One-by-one automatic feeding device and feeding method for strip-shaped revolving body workpieces

A technology of automatic feeding and revolving body, applied in the direction of rotary conveyor, conveyor control device, vibrating conveyor, etc., can solve the problems of low efficiency, high cost, difficult to realize automatic feeding, etc., to improve the degree of automation, Stable and reliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

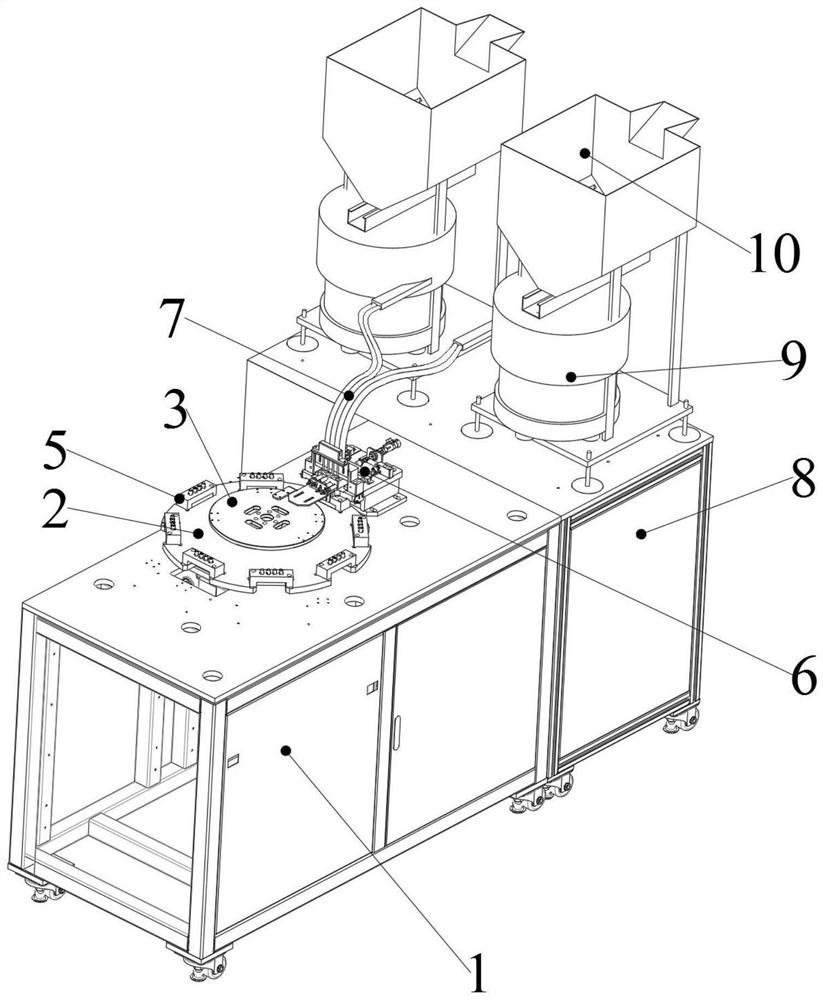

[0030] Such as figure 1 As shown, a bar-shaped rotary workpiece automatic feeding device one by one, including a vibrating plate feeding mechanism, a feeding circular tube 7 and a separate feeding mechanism arranged side by side. The vibrating plate conveying mechanism includes a conveying base 8 , a vibrating plate 9 and a storage funnel 10 . There are two vibrating disks 9. Two vibrating discs 9 are all installed on the charging base 18 . Each vibrating plate 9 has two workpiece output ports. A storage funnel 10 is arranged above the vibration plate 9 . The storage funnel 10 is fixed to the feeding base 18 . The loaded workpieces are stacked in the storage funnel 10 and the vibrating plate 9 .

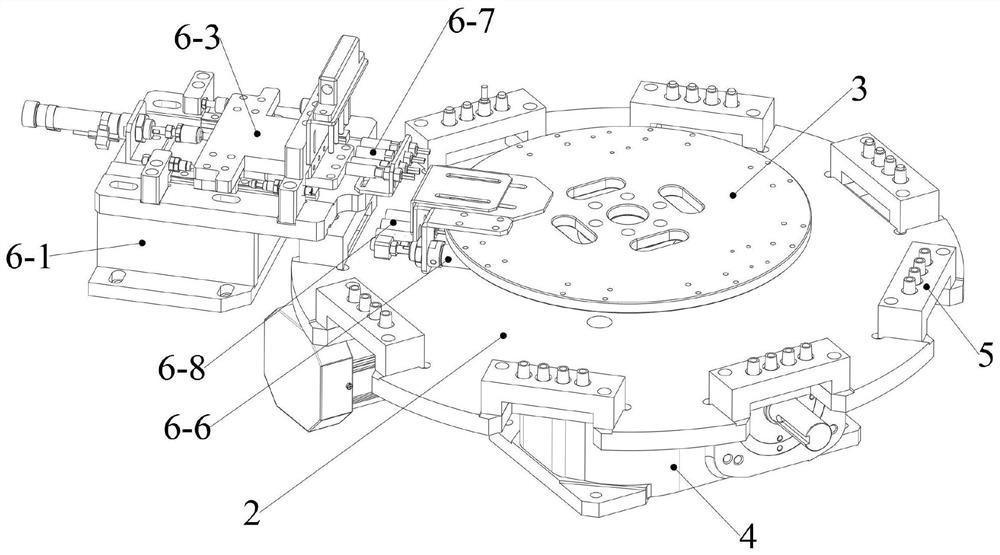

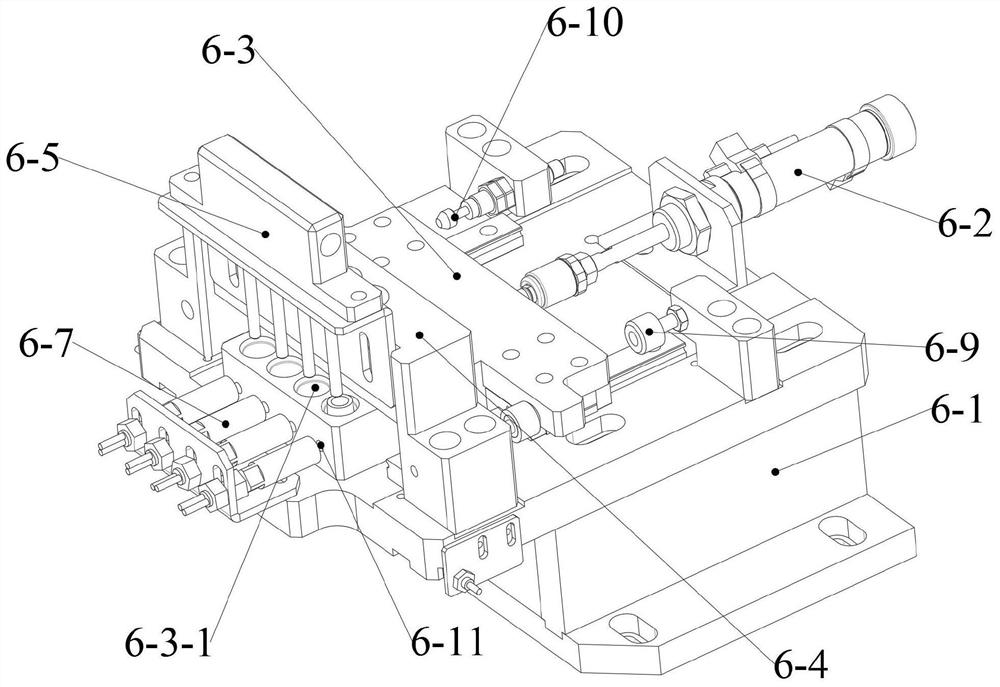

[0031] Such as figure 2 , 3 As shown in and 4, the separation feeding mechanism includes a feeding base 1, a switching turntable 2, a central fixed disk 3, a switching drive element 4, a workpiece storage block 5 and a feeding mechanism 6 one by one. The switching drive elem...

Embodiment 2

[0043] The difference between this embodiment and Embodiment 1 is that each workpiece storage block 5 does not adjust its position by switching the turntable, but adjusts its position by a conveyor belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com