Safety management mechanism of industrial host guard

A security management and host technology, applied in the direction of electrical digital data processing, digital processing power distribution, digital data processing components, etc., can solve the problems of slow installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

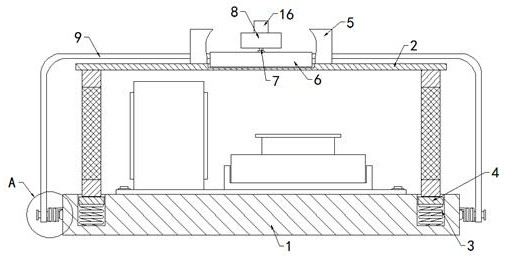

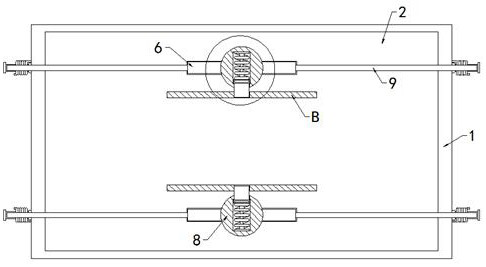

[0025]Example 1figure 1 As shown, the safety management mechanism of this industrial host guard includes a base plate 1 and a machine cover 2. The top of the base plate 1 is provided with an annular groove, and both ends of the inner surface of the annular groove are fixed with first springs 3, two The top of the first spring 3 is jointly fixed with an annular plate 4, the annular plate 4 is in contact with the groove wall of the annular groove, and the cover 2 is in contact with the top of the annular plate 4, and the bottom is located in the annular groove. The position of the cover 2 is initially determined. The top of the cover 2 is fixed with two symmetrical vertical plates 5, the top of the cover 2 is provided with two symmetrical limit slots, and the outer ends of the cover 2 are equipped with elastic In the limiting mechanism, the groove wall of the limiting slot contacts and connects with the limiting block 6, the top of the limiting block 6 is provided with a circular plat...

Embodiment 2

[0026]Example 2 is based on Example 1 asFigure 1-2 As shown, the top of its limit block 6 is rotatably connected with a rotating rod 7 through a second rotating bearing, and the top of the rotating rod 7 is fixedly connected to the top of the circular plate 8. The rotating rod 7 makes the circular plate 8 available in the limit block. The top of the 6 is easily rotated.

Embodiment 3

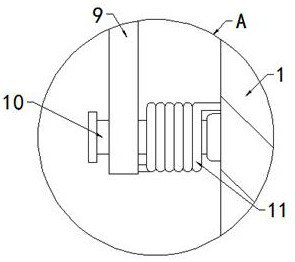

[0027]Example 3 is based on Example 1 asFigure 1-3 As shown, its elastic limit mechanism includes a U-shaped rod 9. Both sides of the base plate 1 are rotatably connected with a cross rod 10 through a second rotating bearing. The bottom ends of the U-shaped rod 9 and the rod walls of the two cross rods 10 A torsion spring 11 is sleeved on the rod wall of the cross bar 10, two ends of the torsion spring 11 are respectively fixedly connected with the U-shaped rod 9 and the base plate 1, and the top of the U-shaped rod 9 of the limit block 6 is fixedly sleeved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com