Display screen structure and driving method thereof

A technology of display screen and sub-pixel, applied in the field of display screen, can solve the problems of increased power consumption of display screen, increase of manufacturing cost of driving unit, reduction of Y-axis, etc., and achieve the effect of saving power consumption and improving the problem of shortening lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

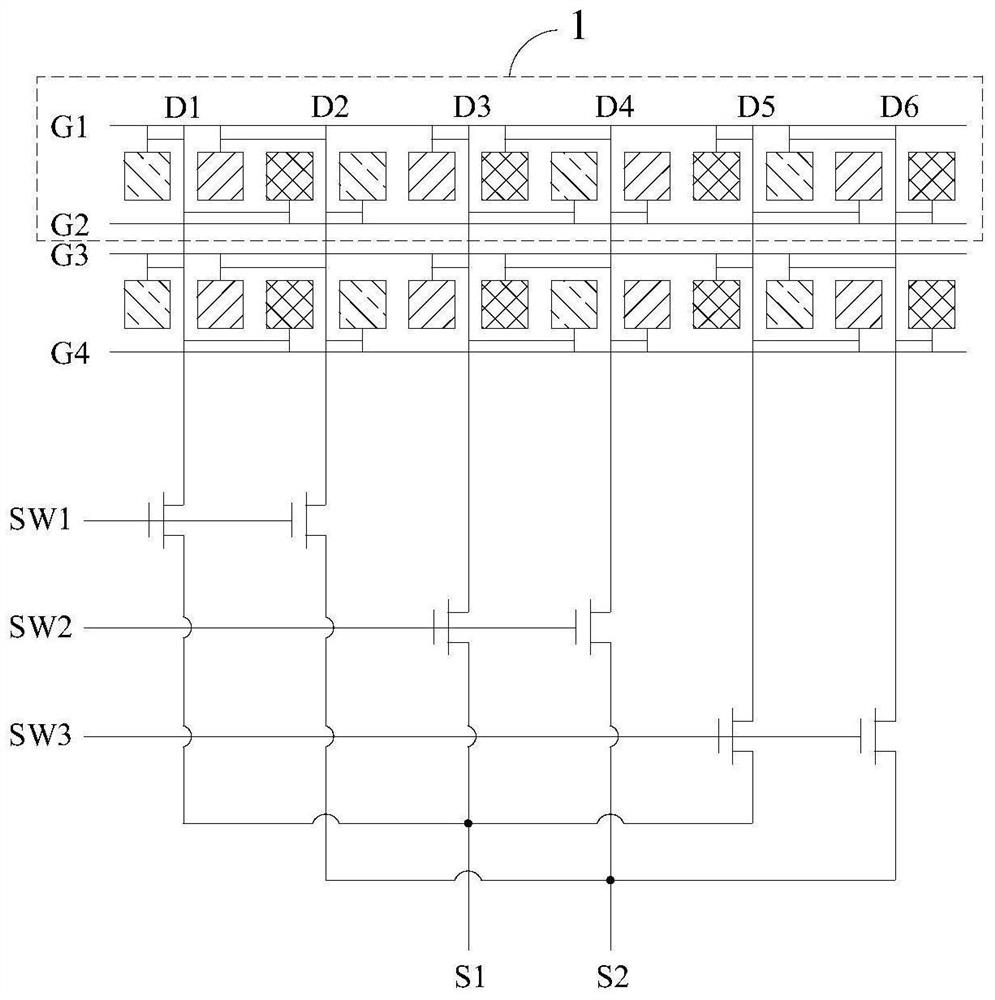

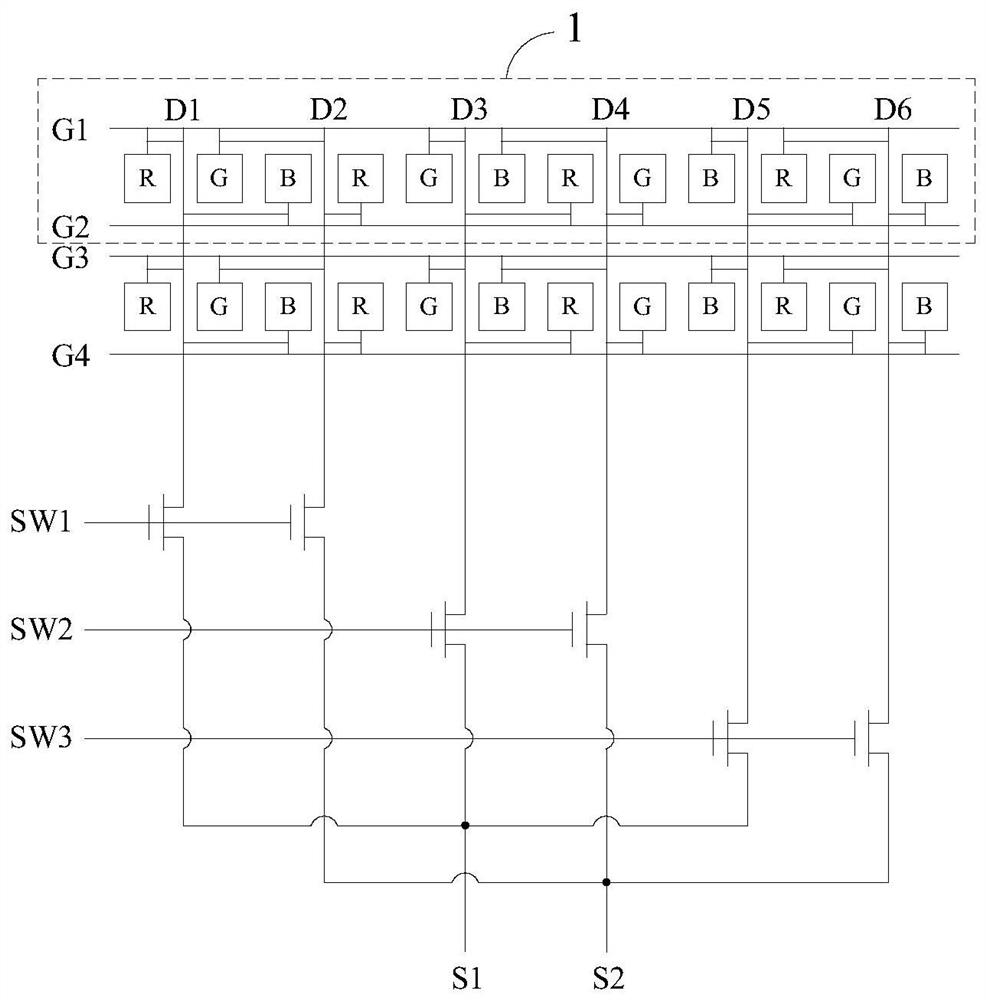

[0044] Please refer to Figure 1 to Figure 4 , Embodiment 1 of the present invention is:

[0045] Please refer to figure 1 and figure 2 , a display structure, including more than two pixel units 1, a first Demux wiring (Demux wiring is also called decompositing unit structure wiring), a second Demux wiring, a third Demux wiring and a plurality of gates Pole wires, one pixel unit 1 is configured with two gate wires and is located between the two gate wires;

[0046] Please refer to figure 1 and figure 2 , each of the pixel units 1 includes six columns of sub-pixel pairs arranged in sequence from left to right, the sub-pixel pairs in the first column and the sub-pixel pairs in the second column are divided into the first sub-pixel group, and the sub-pixel pairs in the third column are divided into sub-pixel groups. The sub-pixel pair in the column and the sub-pixel pair in the fourth column are divided into the second sub-pixel group, and the sub-pixel pair in the fifth c...

Embodiment 2

[0057] Please refer to Figure 5 , the second embodiment of the present invention is:

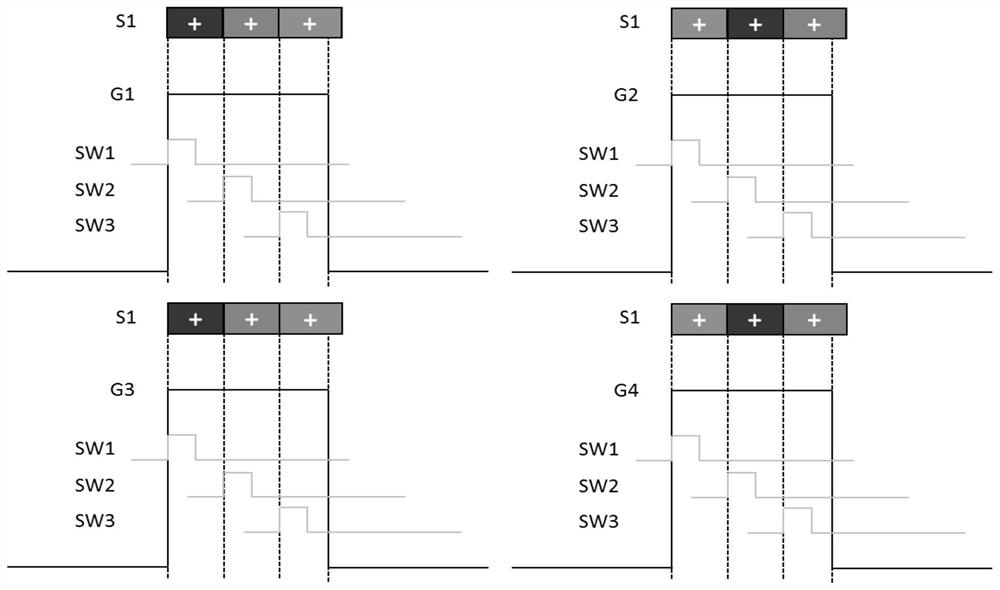

[0058] A method for driving a display screen structure, comprising the following steps:

[0059] Step S1, in one pixel unit 1, controlling one of the two gate lines to be turned on;

[0060] Step S2, during the opening period of a gate line, sequentially control the opening of the first Demux line, the second Demux line and the third Demux line; during the opening period of the first Demux line, control the source line to transmit the signal To the pixel pair connected to the data traces at the first and second locations; during the turn-on of the second Demux trace, the control source trace transmits the signal to the data trace connections at the third and fourth locations during the turn-on period of the third Demux wiring, control the source wiring to transmit the signal to the pixel pair connected to the data wiring at the fifth position to the sixth position;

[0061] Step S3, cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com