Preparation method of dicyclopentadiene dioxide based on modified nano MgO loaded heteropolyacid catalyst

A technology of dicyclopentadiene dioxide and loaded heteropolyacid, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problem that heteropolyacids are easy to fall off. and other problems, to achieve the effect of environmental protection process method, high activity, improved service life and shortened life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

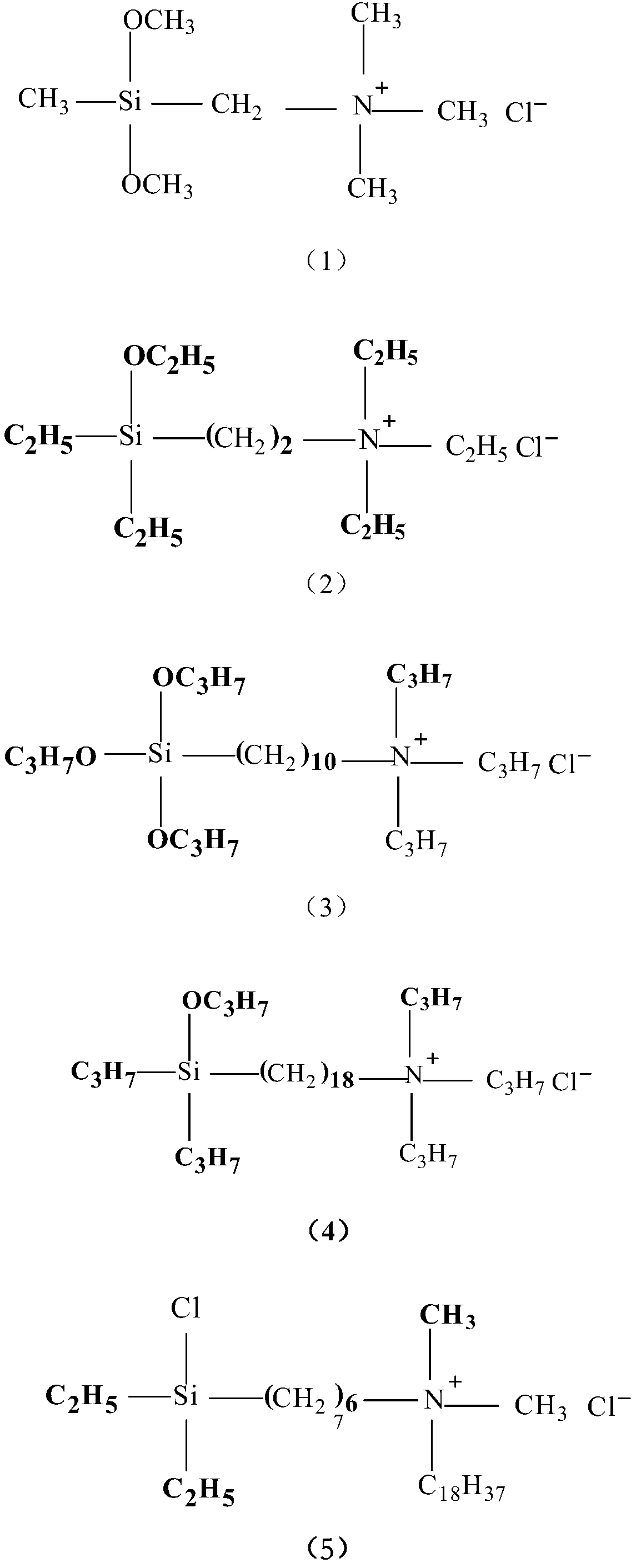

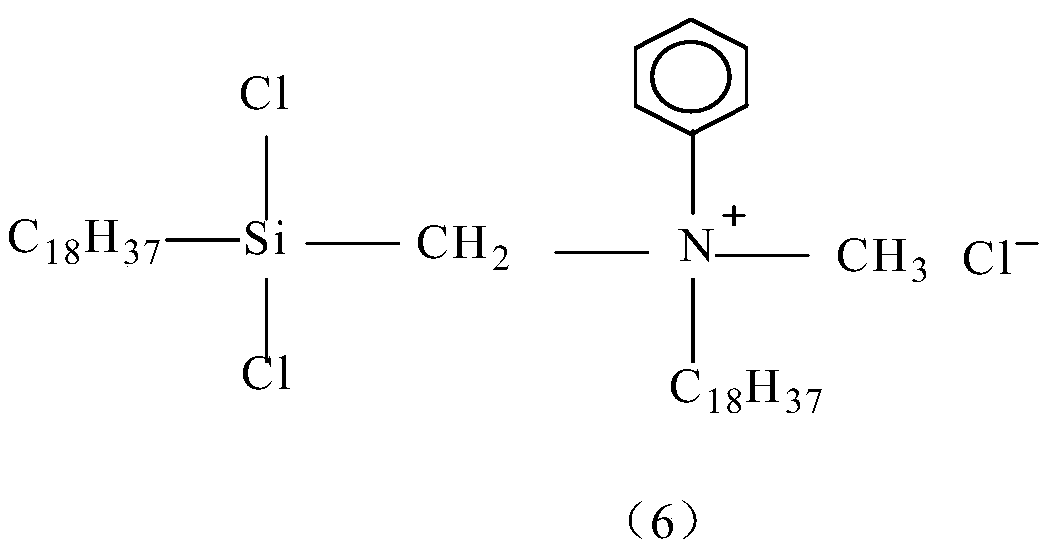

[0020] Example 1 illustrates the preparation method of the modified nanometer MgO-supported heteropolyacid compound catalyst, and Examples 2-22 illustrate the preparation method of dicyclopentadiene dioxide based on the modified nanometer MgO supported heteropolyacid compound catalyst. The silylating reagents used for catalyst modification treatment in Examples 2-7 have molecular structural formulas as shown in (1)-(6) respectively:

[0021]

[0022]

Embodiment 2~22

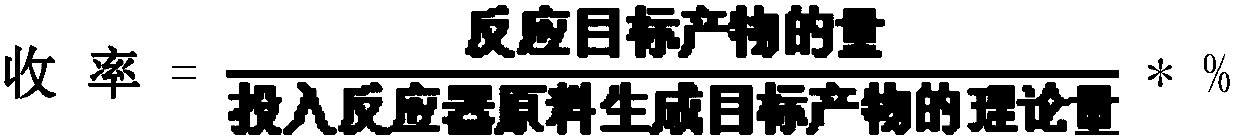

[0023] In embodiment 2~22, the definition of dicyclopentadiene dioxide reaction yield:

[0024]

[0025] Example 1

[0026] Nano-MgO is selected as the inorganic oxide carrier, the molecular structure of the silylation reagent used is shown in formula (3), acetonitrile is used as the solvent, and the catalyst is prepared according to the following steps:

[0027](1) According to the molar ratio of inorganic oxide powder to silylation reagent 100:1, the mass ratio of solvent to inorganic oxide powder is 4:1, weigh the above-mentioned raw materials and put them into the reactor, mix and stir to make them react, and the reaction temperature is 90 °C, the reaction time is 10 hours;

[0028] (2) The product in step (1) is filtered, the solid powder is separated from the solution, and the isolated solid powder is washed with the solvent in step (1), and the solvent used for each washing is mixed with the inorganic oxide in step (1). The powder mass ratio is 4:1, remove the unre...

Embodiment 14~22

[0042] Further illustrate the stability of the modified nanometer MgO loaded heteropolyacid compound catalyst used in the present invention, the reaction raw material that drops into every time is identical, and catalyst is reused, and adopts suspension reactor, and concrete steps: to volume is 500ml containing inner cooling plate In the autoclave of tube, drop into the used catalyst 15g of embodiment 2, with 316L stainless steel wire mesh, catalyst adopts hanging basket mode to be fixed on the inner cooling coil of autoclave, drop into 98% dicyclopentadiene 60g, mass percentage is 50 % hydrogen peroxide 74ml, acetone 222ml, reaction temperature 60 ~ 62 ℃, reaction pressure 5MPa, mechanical stirring to ensure that the reaction raw materials and the catalyst fully contact, the materials are mixed evenly, the reaction time is 10h, and the reaction is terminated. The material is cooled to room temperature and discharged. The water and solvent were separated to obtain a crude prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com