Preparation method of dicyclopentadiene dioxide based on modified nano aluminum oxide loaded heteropolyacid type compound catalyst

A technology of dicyclopentadiene dioxide and aluminum oxide, applied in organic compound/hydride/coordination complex catalysts, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. It can solve the problems that heteropolyacids are easy to fall off, etc., and achieve the effects of environmental protection technology, shortened service life and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

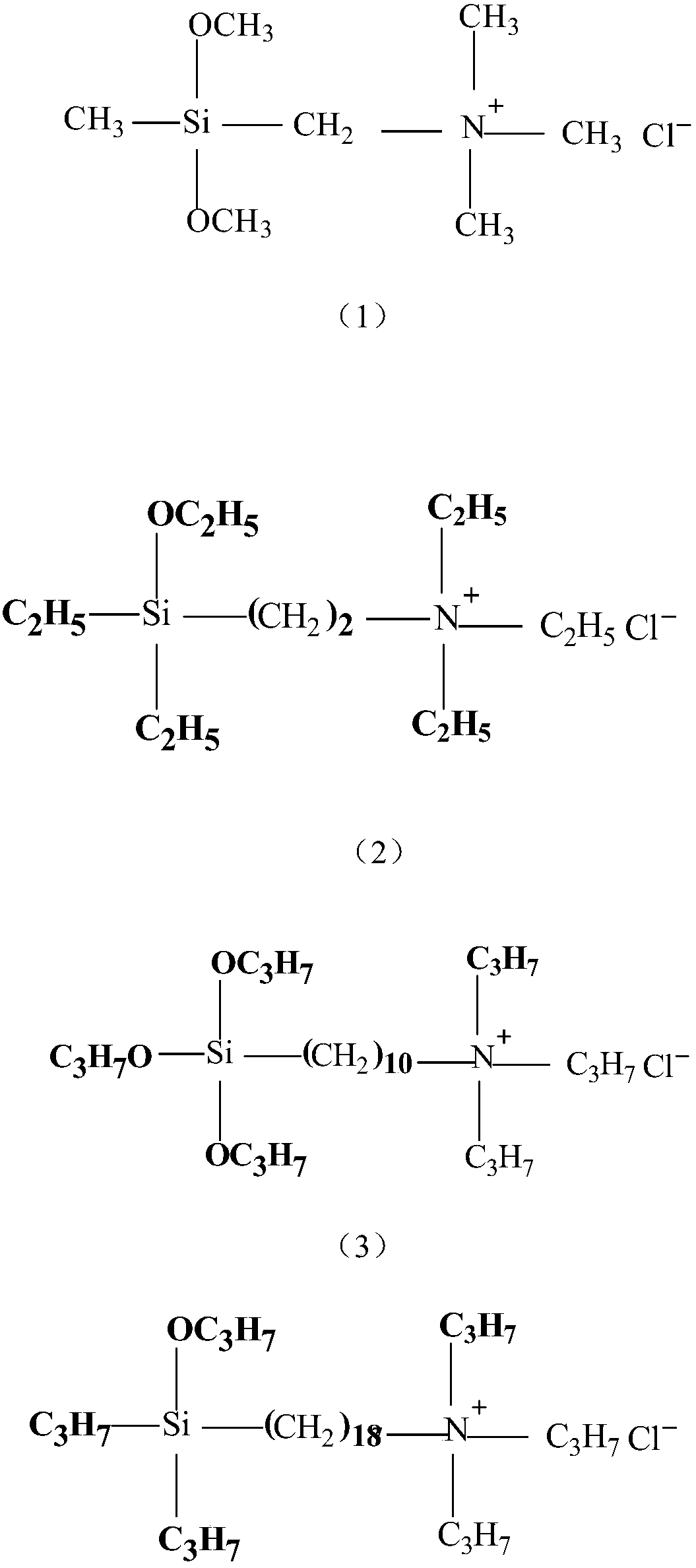

[0021] Example 1 illustrates the preparation method of the modified nano-alumina oxide-supported heteropoly acid compound catalyst, and Examples 2 to 30 illustrate the preparation of dicyclopentadiene dioxide based on the modified nano-aluminum oxide-supported heteropoly acid compound Preparation. The molecular structural formulas of the silylation reagents used in the catalyst modification treatment of Examples 2-7 are as shown in (1) to (6):

[0022]

[0023]

Embodiment 2~22

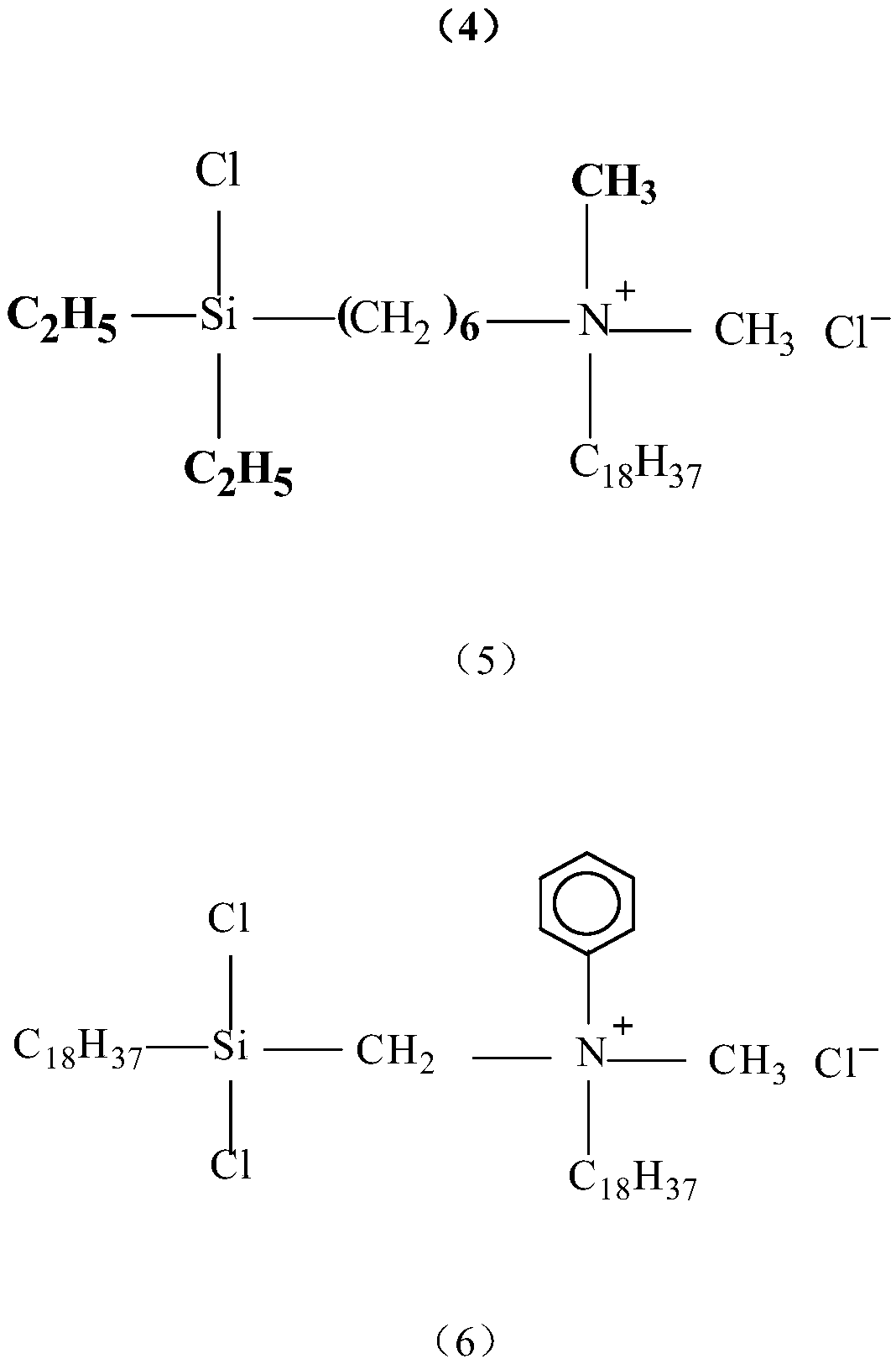

[0024] In Examples 2-22, the reaction yield of dicyclopentadiene dioxide is defined as:

[0025]

[0026] Example 1

[0027] Select nano aluminum oxide as the inorganic oxide carrier, the molecular structure of the silylation reagent used is shown in the molecular structure (2), benzene is used as the solvent, and the catalyst is prepared according to the following steps:

[0028] (1) According to the molar ratio of inorganic oxide powder to silylation reagent of 300:1 and the mass ratio of solvent to inorganic oxide powder of 4:1, weigh the above-mentioned raw materials into the reactor, mix and stir to make the reaction, the reaction temperature is 50 ℃, the reaction time is 15 hours;

[0029] (2) Filter the product in step (1), separate the solid powder from the solution, and wash the separated solid powder with the solvent in step (1). The solvent used for each wash is the same as the inorganic oxide in step (1). The powder mass ratio is 5:1, remove the unreacted silylation reage...

Embodiment 2~7

[0034] Using dicyclopentadiene as the raw material and hydrogen peroxide as the oxidant, the epoxidation reaction adopts a suspended bed reactor to modify the heteropoly acid type compound and its mass percentage composition in the nano alumina supported heteropoly acid type compound catalyst See Table 1. Specific steps: Into an autoclave with a volume of 500ml containing an inner cooling coil, put the modified nano-alumina oxide-supported heteropoly acid compound catalyst, solvent, and dicyclopentadiene according to the process requirements, turn on the stirring, and heat up the material. After the reaction material reaches the process setting temperature, the hydrogen peroxide is added into the reaction kettle by a metering pump, the cooling water system is turned on, and the cooling water flow is adjusted to ensure that the reaction temperature is within the process setting range. After the reaction is over, turn on the cooling water to cool the material to room temperature....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com