Manufacturing method of storage battery box and the storage battery box

A battery box and manufacturing method technology, applied in the direction of manufacturing tools, battery pack parts, circuits, etc., can solve the problems of inability to effectively accommodate multiple cells and low loading density, and achieve improved cell loading density and high sealing performance, the effect of suppressing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

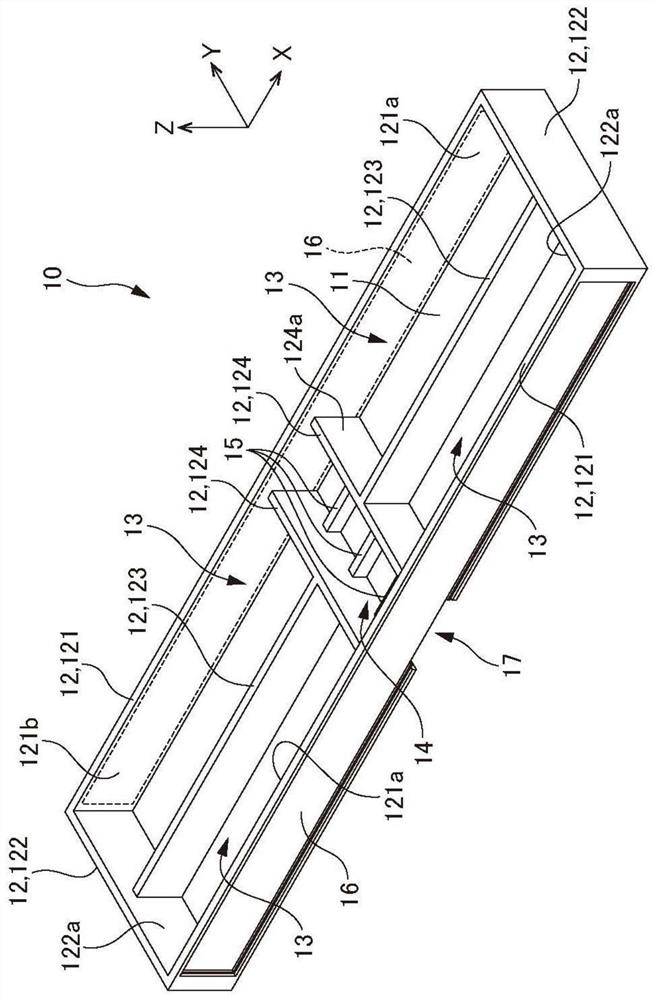

[0048] Such as figure 1 As shown, the battery case 10 is composed of a box-shaped container having a rectangular bottom wall 11 in plan view and a standing wall 12 standing upright from the upper surface of the bottom wall 11 with an upper opening. The battery case 10 is formed in an elongated shape in the X direction in the drawing. In addition, among the directions shown in the figure, the X direction represents the longitudinal direction of the battery case 10 . The Y direction represents the width direction of the battery case 10 . The Z direction represents the height direction of the battery case 10 .

[0049] The standing wall portion 12 has side wall portions 121 , 121 , end wall portions 122 , 122 , intermediate wall portions 123 , 123 , and central end wall portions 124 , 124 . The side wall portions 121 , 121 are arranged at both end portions in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com