Mechanism capable of achieving automatic rotating and automatic pressing of cylindrical valve bodies

A technology of automatic rotation and pressing mechanism, applied in metal processing machinery parts, clamping, supporting and other directions, which can solve the problems of low efficiency and poor effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

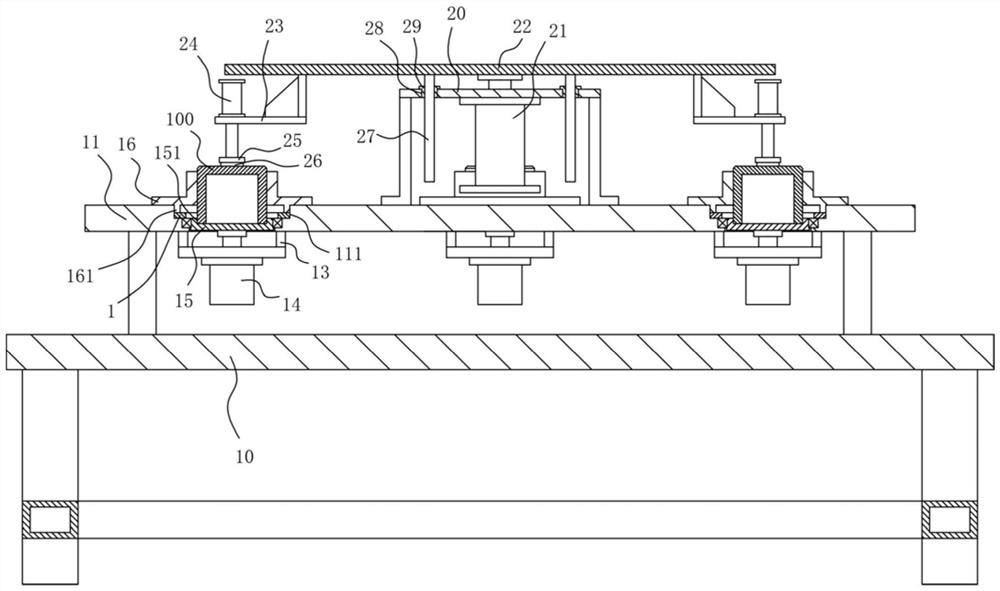

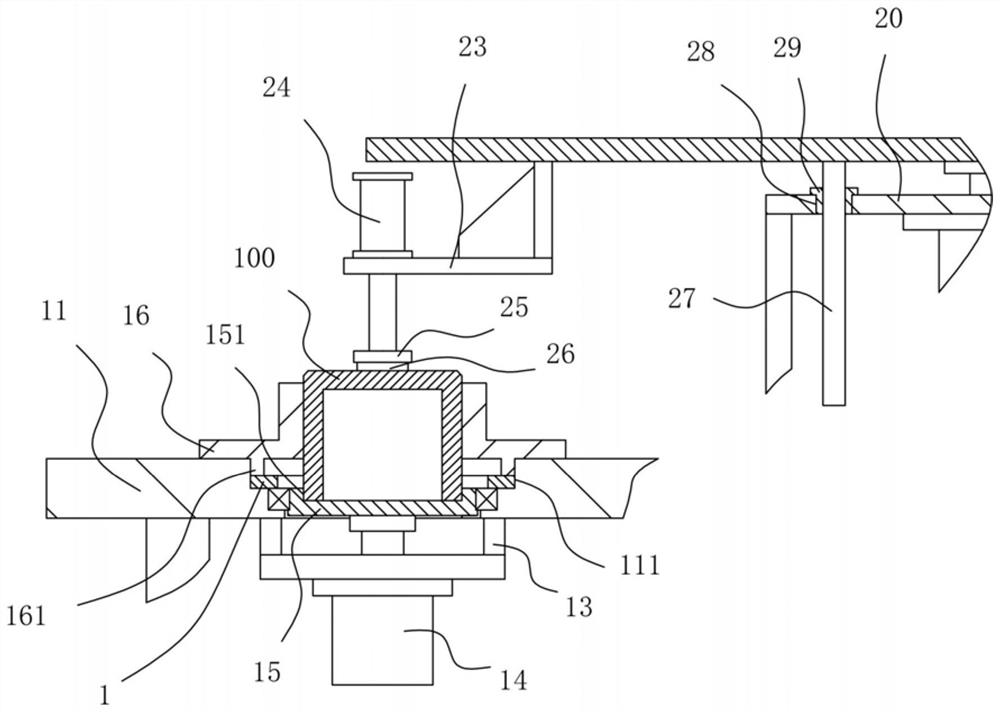

[0021] Example: see Figure 1 to Figure 3 As shown, a cylindrical valve body can automatically rotate and automatically compress the mechanism, including a frame 10, and an upper support frame 11 is fixed on the top surface of the top plate of the frame 10;

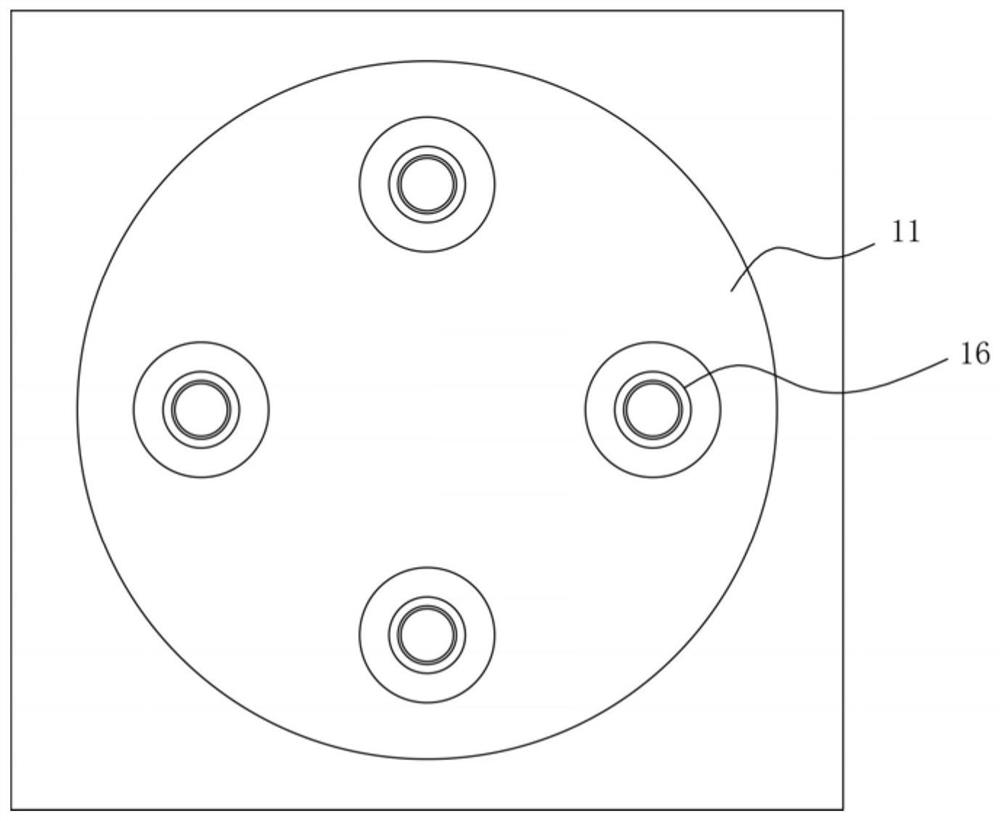

[0022] The edge of the top plate of the upper support frame 11 is formed with a plurality of connecting step through holes 111, and the bottom surface of the edge portion of the top plate of the upper support frame 11 is fixed with a plurality of motor frames 13, and the middle part of the bottom surface of the bottom plate of the motor frame 13 is fixed with a rotating Servo motor 14, the output shaft of the rotary servo motor 14 passes through the top surface of the bottom plate of the motor frame 13 and is fixed with a rotating plate 15, the rotating plate 15 is inserted and sleeved in the connecting step through hole 111, and the middle part of the top surface of the rotating plate 15 is formed with Place the groove 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com