Split assembling type cable house-service hole plugging device

A plugging device and assembled technology, applied in the direction of electrical components, pipes, pipes/pipe joints/fittings, etc., can solve the problems of loose cables, increased voids, poor fire performance, etc., and achieve the effect of avoiding looseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

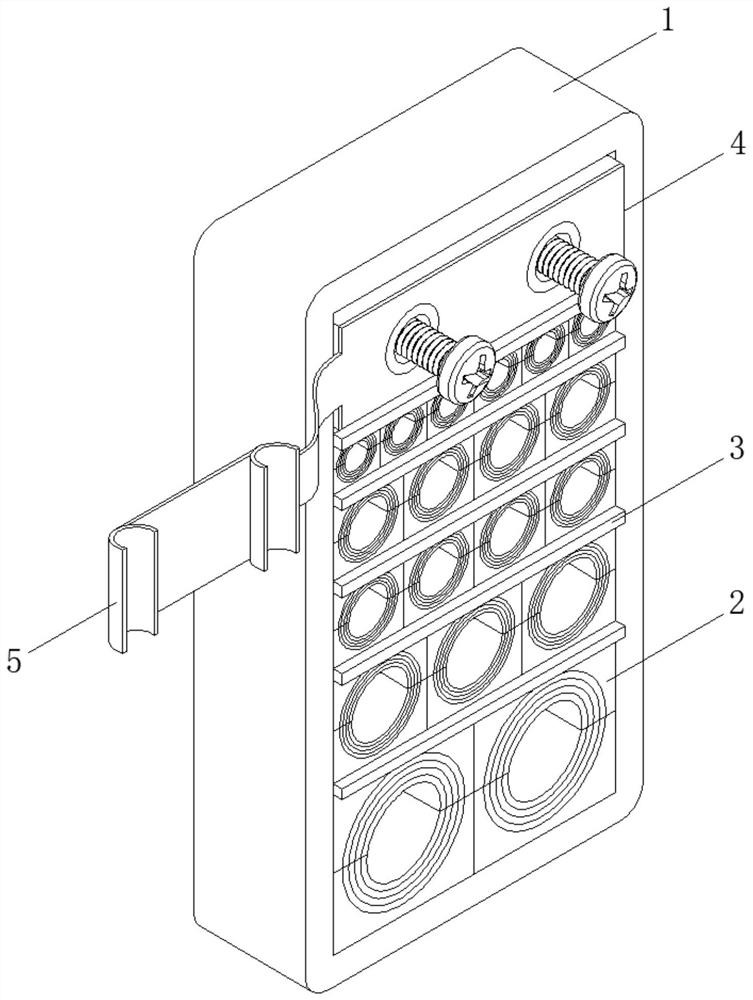

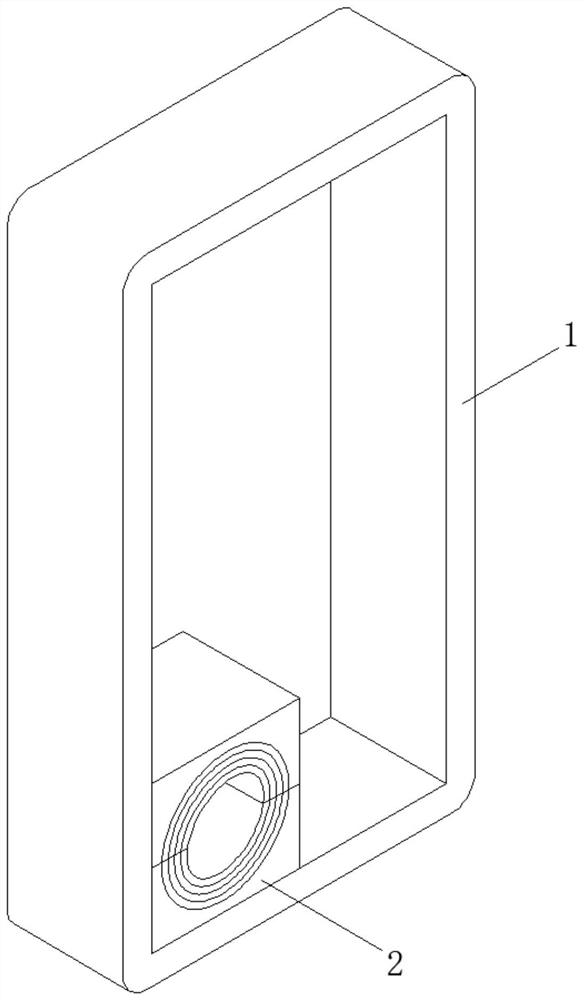

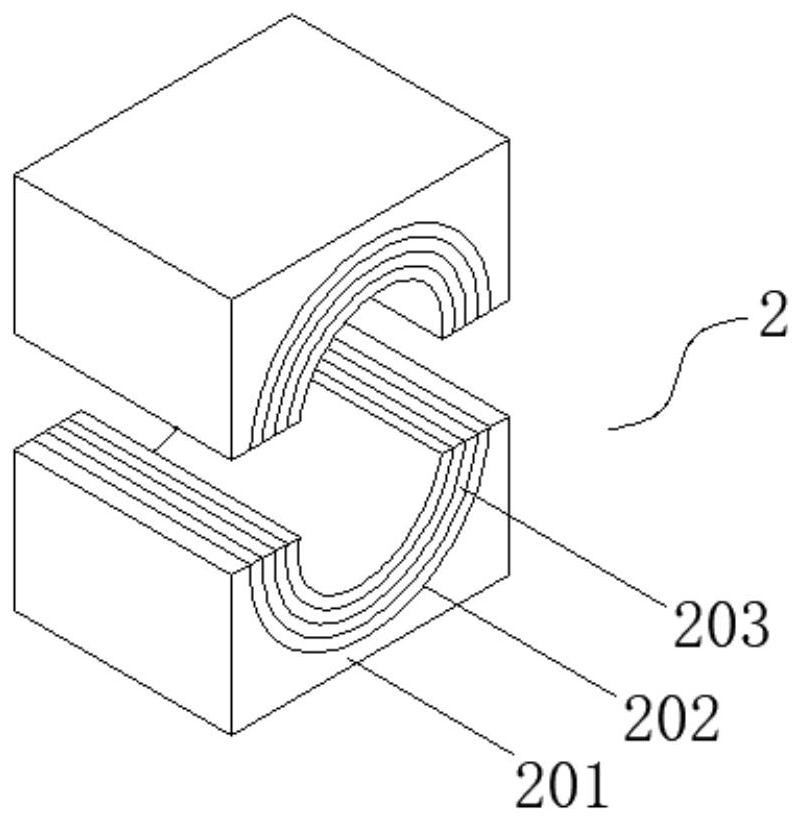

[0026] see Figure 1~6 , in an embodiment of the present invention, a split and assembled cable entry hole sealing device includes a frame body 1, a plugging component 2, a partition component 3, a pressing mechanism 4 and a dustproof component 5, and the frame body 1 Several layers of blocking components 2 are arranged in sequence from bottom to top, and a layer of partitioning components 3 is horizontally arranged between each layer of blocking components 2, and the front and rear sides of the partitioning component 3 extend horizontally to the bottom of the frame body 1. Externally, the top of the frame body 1 is horizontally provided with a pressing mechanism 4, and the upper and lower ends of the pressing mechanism 4 are respectively in contact with the inner side wall of the frame body 1 and the top of the longest layer partition assembly 3, and the front of the pressing mechanism 4 A dustproof assembly 5 is arranged on the side wall.

[0027] exist figure 1 , figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com