Reciprocating type interfacial agent smearing device for foamed ceramic insulation plate

A technology of foaming ceramics and thermal insulation boards, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of unevenness and low efficiency of manual application, and achieve the effect of uniform and efficient application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

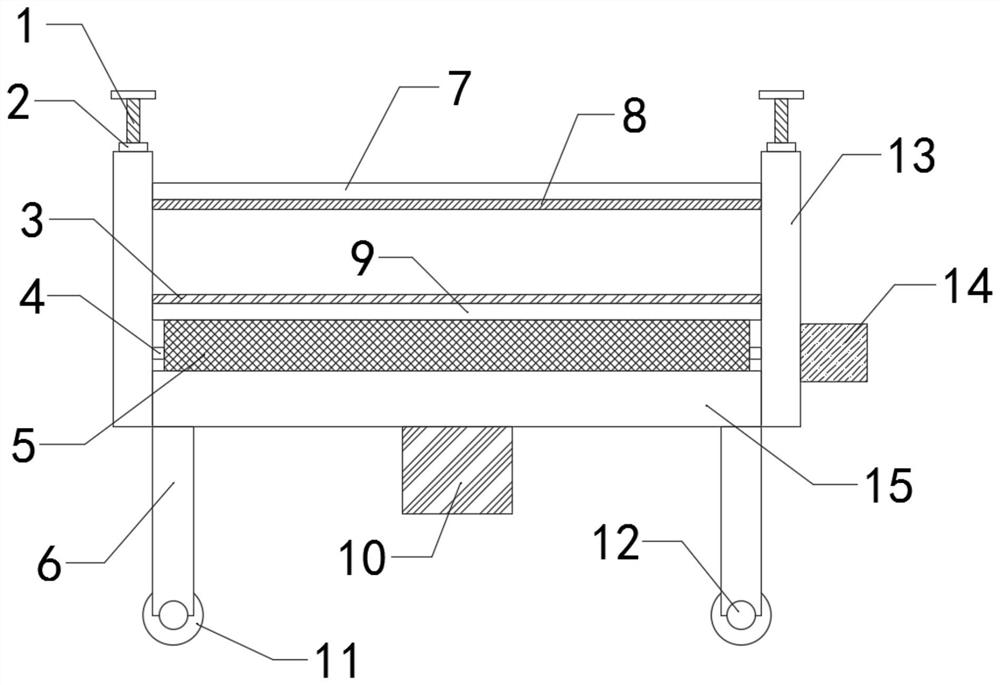

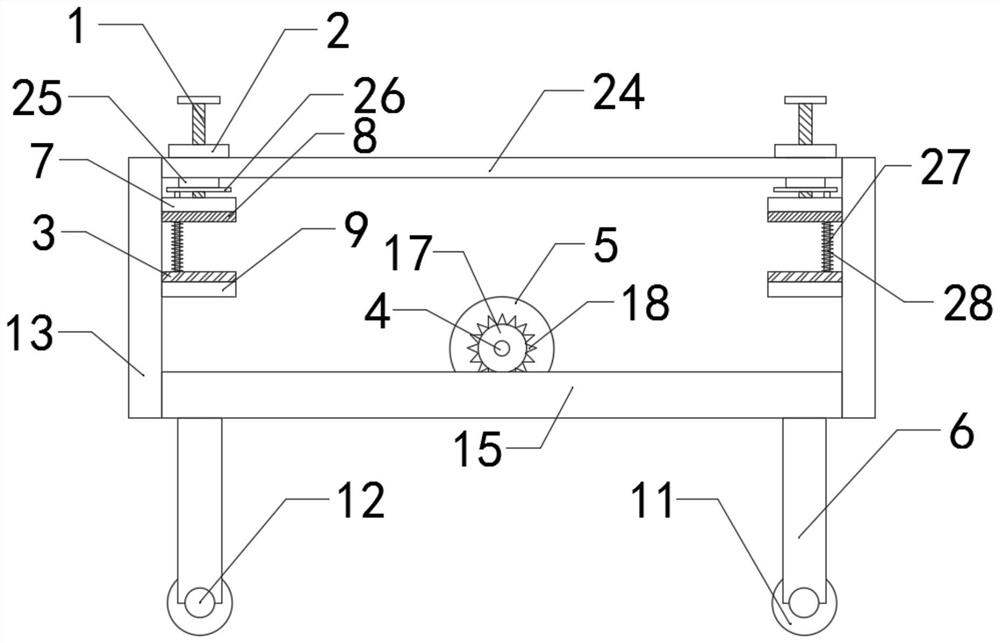

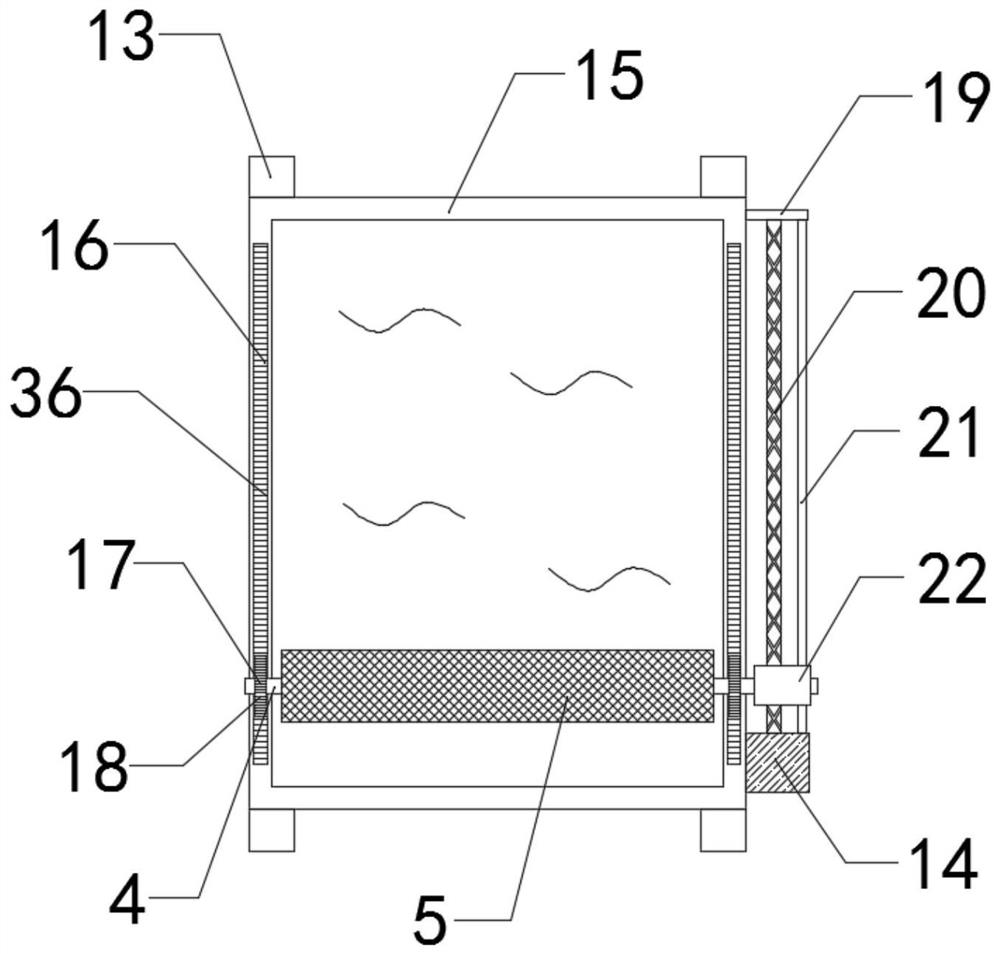

[0023] see Figures 1 to 5 , In the embodiment of the present invention, a reciprocating device for coating an interface agent for a foamed ceramic thermal insulation board includes a device mainboard 15, which is used to store the interface agent, and the lower end of the device mainboard 15 is connected to four supports The legs 6 are connected, and the lower ends of the four supporting legs 6 are connected with the moving wheel 11 through the rotating shaft 12. The user moves the reciprocating foamed ceramic insulation board with the interface agent applicator through the moving wheel 11. The device main board 15 There is a fixing mechanism on it, which can fix different sizes of foamed ceramic insulation boards. The main board 15 of the device is also provided with a reciprocating smearing mechanism, and the foamed ceramic insulation board is evenly smeared by the reciprocating smearing mechanism.

[0024] The specific form of the fixing mechanism is not limited. In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com