Lifting device for gypsum board ceiling for interior decoration

A gypsum board and interior decoration technology, which is applied in the direction of construction and building construction, and can solve problems such as boom collision, clamping device loosening, and gypsum board damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

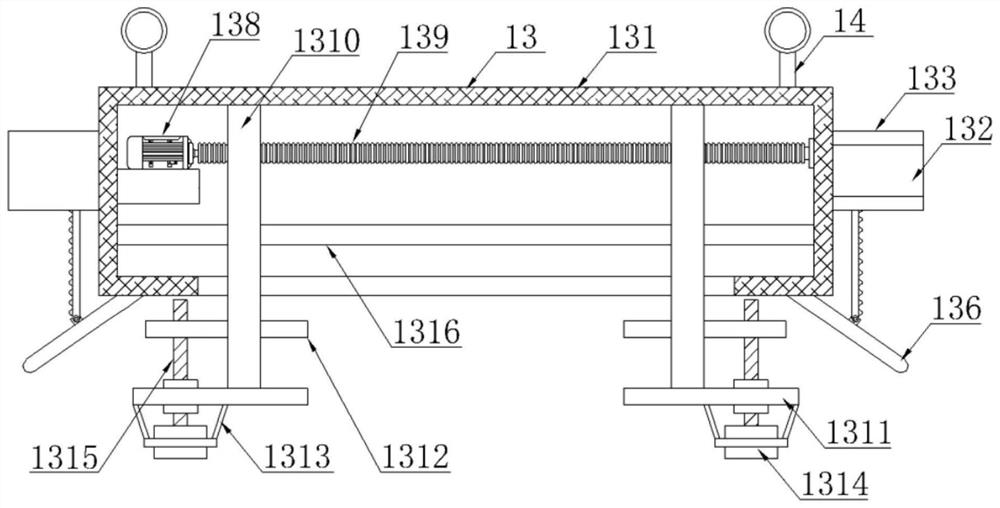

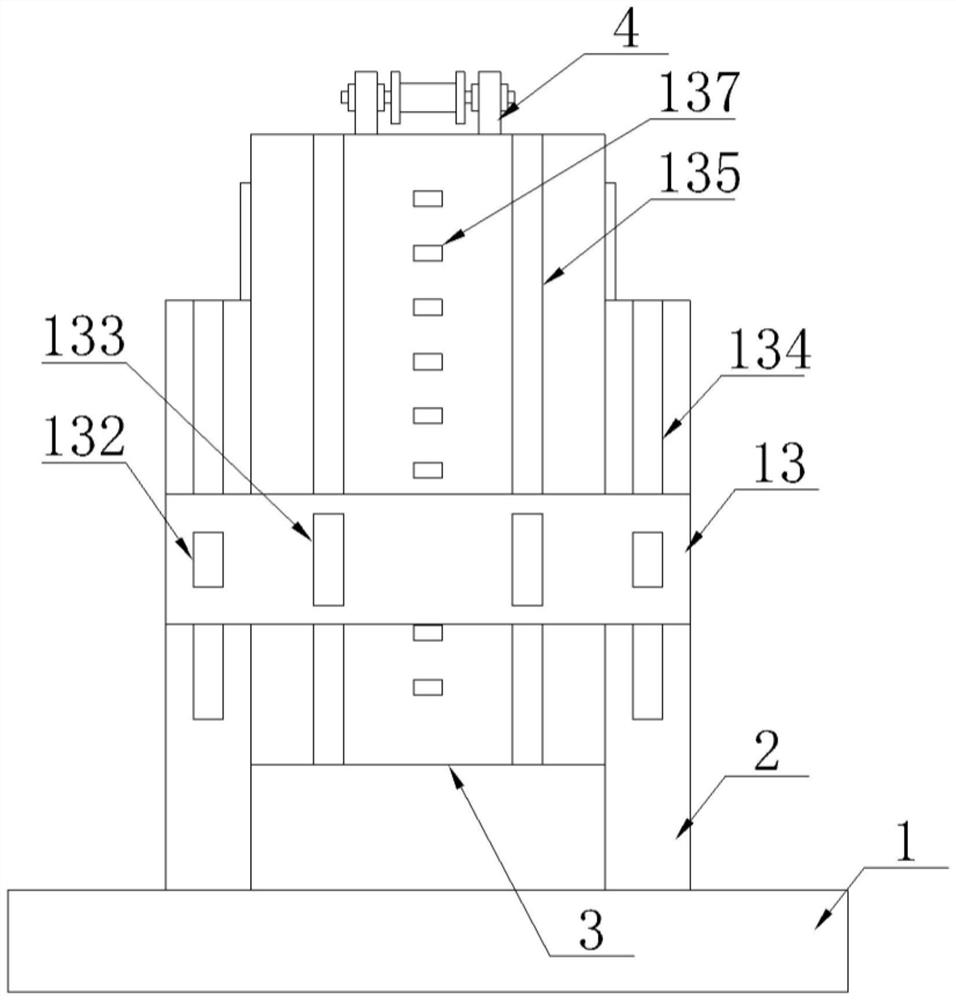

[0025] 1) Preparation for lifting the gypsum board ceiling: first, lower the gypsum board lifting device 13 to the bottom through the winding machine 12, then start the motor 138, and the motor 138 drives the two-way screw rod 139 to rotate so that the two groups of movable splints 1310 are separated from each other. At this time, the gypsum board The plate ceiling is placed between the pressing plate 1312 and the bottom plate 1311, and then the motor 138 is started to make the movable splints 1310 close to each other to clamp both sides of the gypsum board ceiling, and then the rotating motor 1314 is started, and the rotating motor 1314 drives the screw rod 1315 to rotate, so that The pressing plate 1312 moves downward to clamp the gypsum board ceiling;

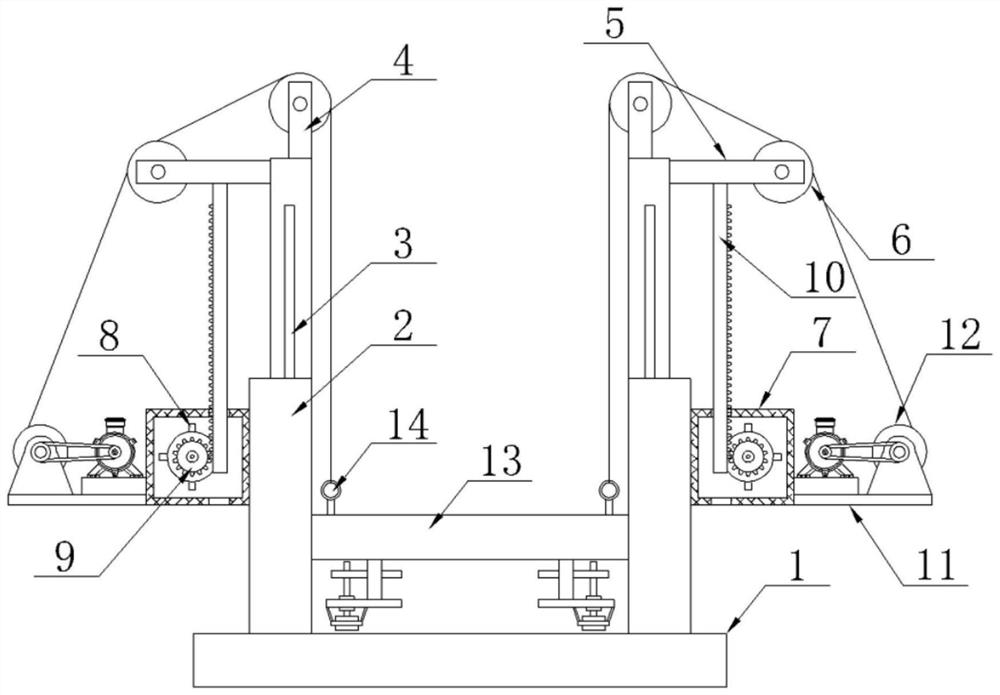

[0026] 2) Lifting of the gypsum board ceiling: After the gypsum board ceiling is fixed, start the drive motor 8 according to the height of the transfer position, the drive motor 8 drives the gear 9 to rotate, and the rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com