Film mulching device for agricultural planting

A film-covering device and agricultural technology, applied in applications, plant protection, plant protection covers, etc., can solve problems such as cumbersome operations and affecting work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

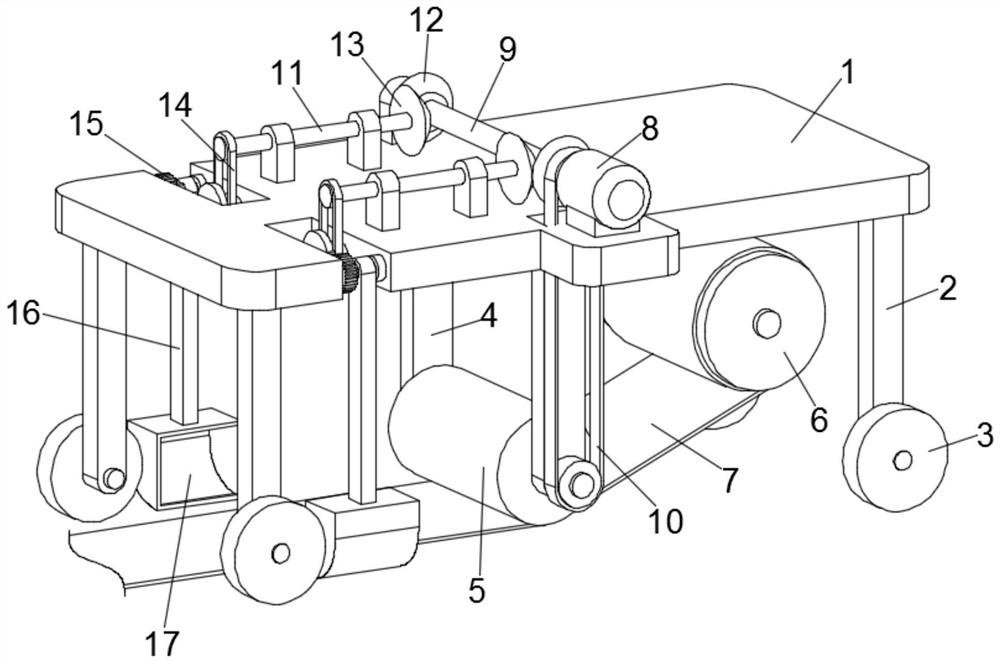

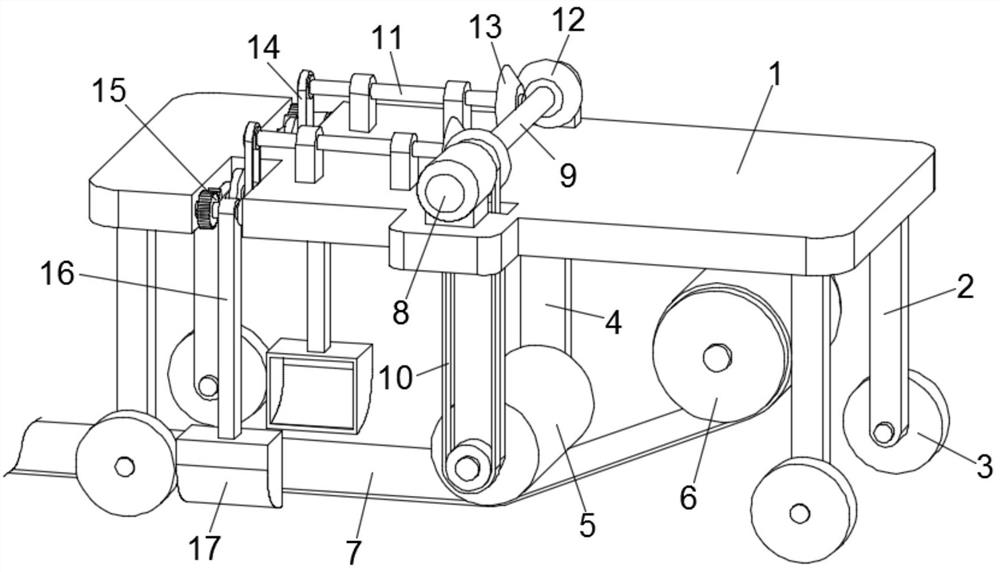

[0024] see Figure 1-2 , a film covering device for agricultural planting, comprising a platform 1, the four corners of the bottom of the platform 1 are fixed with legs 2, the lower ends of the legs 2 are rotatably mounted with walking wheels 3; the lower end of the platform 1 is fixed with a support frame 4. The bottom of the support frame 4 is rotatably installed with a coating roller 5, and the lower end surface of the platform 1 is also rotatably installed with a winding wheel 6, and a film 7 is wound on the winding wheel 6; the platform 1 A drive motor 8 is fixedly installed on the upper end surface, and a first transmission shaft 9 is installed on the output end of the drive motor 8, and a first transmission belt 10 is rotatably connected between the first transmission shaft 9 and the laminating roller 5, and the platform 1. A second transmission shaft 11 is installed on both sides of the upper end surface for symmetrical rotation. The second transmission shaft 11 is ver...

Embodiment 2

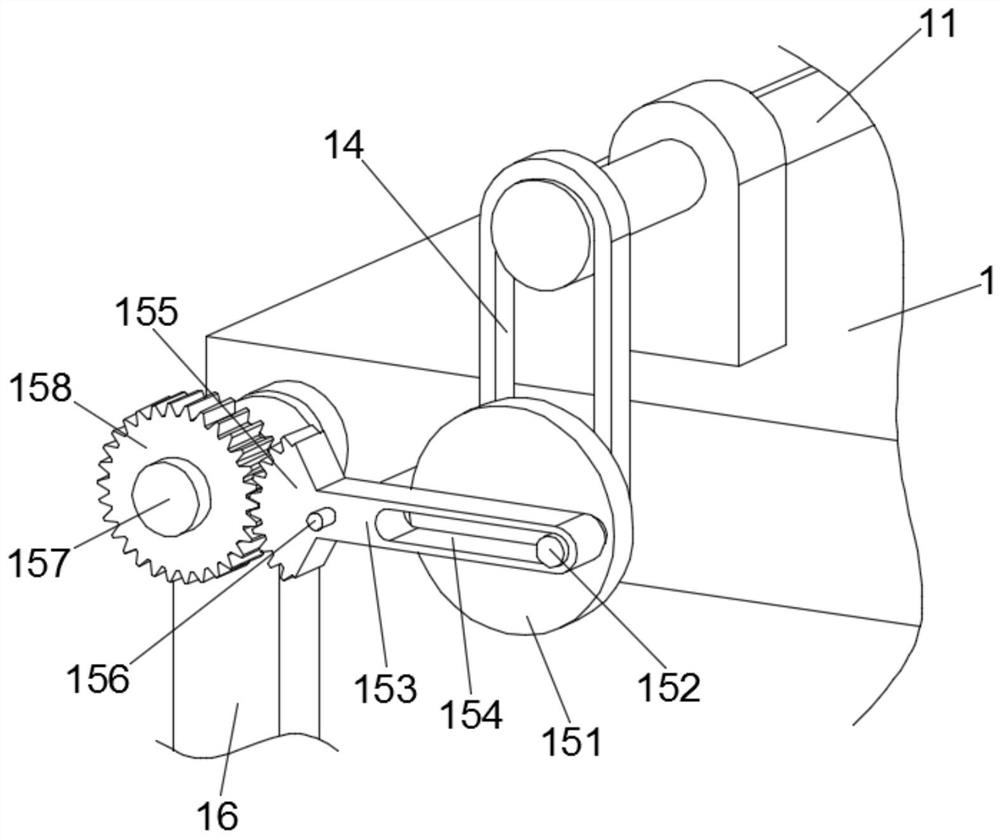

[0034]A film covering device for agricultural planting, comprising a platform 1, legs 2 are fixed at the four corners of the bottom of the platform 1, the lower end of the legs 2 is rotatably mounted with a walking wheel 3; the lower end of the platform 1 is fixed with a support frame 4 , the bottom of the support frame 4 is rotatably equipped with a coating roller 5, and the lower end surface of the platform 1 is also rotatably installed with a winding wheel 6, and a film 7 is wound on the said winding wheel 6; A drive motor 8 is fixedly installed on the end face, and a first transmission shaft 9 is installed on the output end of the drive motor 8, and a first transmission belt 10 is rotatably connected between the first transmission shaft 9 and the coating roller 5. The platform 1 A second transmission shaft 11 is installed on both sides of the upper end surface for symmetrical rotation, and the second transmission shaft 11 is vertically distributed with the first transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com