Preparation device of cut stems for cigarettes and operation method thereof

A technology of preparation device and operation method, which is applied in the fields of tobacco, application, and treatment of tobacco, can solve problems affecting consumer experience, affecting the ash of cigarette packs, and blackening of cigarette ash, so that it is not easy to elute and repair, Easy to promote and reduce the effect of crushing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

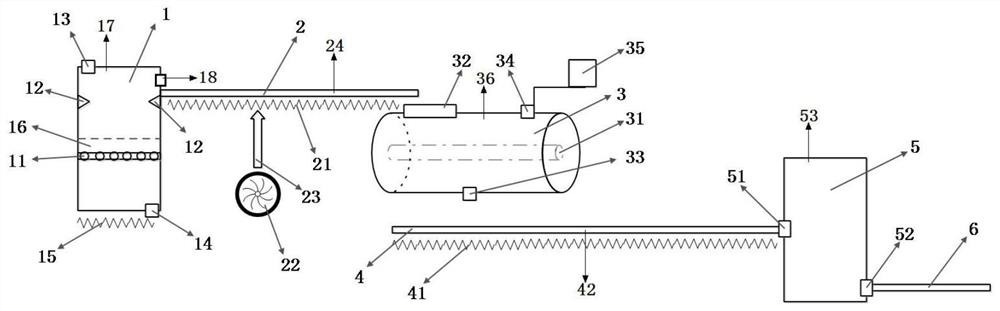

[0049] The preparation device of whole this shredded stem is as attached figure 1 shown.

[0050] In addition, in this example, the cigarette ash whiteness is detected by conventional powder whiteness detection method, and the ash index is calculated by the aforementioned method.

Embodiment 1

[0052] Such as figure 1 Shown, the preparation method of shredded stem for tobacco specifically comprises the following steps:

[0053] a. Close the water outlet 14, put the tobacco stems into the perforated transfer filter disc 11 in the tobacco stem elution chamber 17, add water through the first feeding port 13 until the The liquid level of the eluent 16 can completely submerge the tobacco stems, then turn on the first heater 15, heat the eluent 16 to elute the tobacco stems, and lift the perforated transmission filter disc 11 to make its height reach the required level. On the fixed buckle 12, stabilize for 0.5-1min, make the eluent 16 in the tobacco stem fall back to the bottom of the tobacco stem elution chamber 17, and open the water outlet 14 to release the eluent 16;

[0054] According to actual production needs, the water outlet 14 can be closed again, and after lowering the height of the perforated transfer filter disc 11, the above elution process can be repeated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com