A method for processing cut stems that can improve the whiteness of cigarette ash

A treatment method and cut stem technology, which is applied in the field of cut stem treatment that can improve the whiteness of cigarette ashes, can solve the problems of cigarette ashes turning black, easy to burst, and black burning ash, and achieve improved combustibility, obvious shrinkage, and ash The effect of index improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

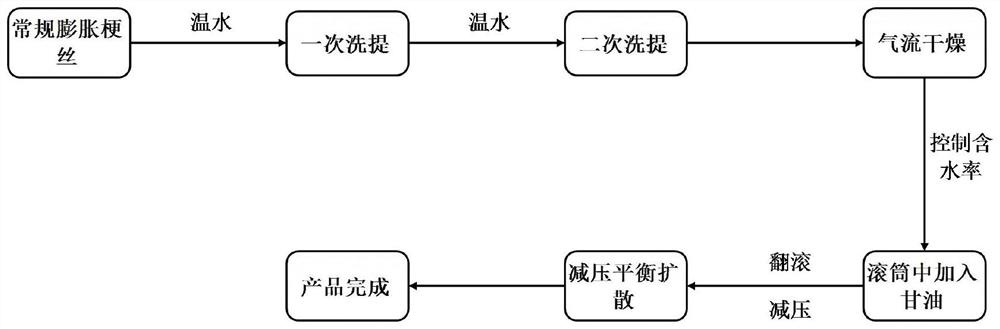

[0034] Add 40°C warm water to the conventional expanded cut stems and filter them for immersion for 30 minutes. After repeating the dipping once, the cut stems are dried by air drying process to control the moisture content at about 8%. The eluted and dried cut stems are transferred into a rotating drum, sprayed into glycerin with 5% mass of cut stems under the condition of constant rotation, and taken out after 40min under reduced pressure and equilibrium diffusion at 400 mbar, which is the method described in the present invention. Cut stem products that enhance the whiteness of cigarette ashes.

[0035] The cutting rate of cut stems obtained by the above method is about 12%. The shredded stem was used to make cigarette (2#) with shredded tobacco according to the ratio in the original formula, and compared with the original cigarette (1#), the results are as follows:

[0036] Sample serial number Ash whiteness Tuff Index 1# 96.2 6.1 2# 121.2 4.9 ...

Embodiment 2

[0040] Add 60°C warm water to the conventional expanded cut stems and filter them for 20 minutes. After repeating the dipping once, the cut stems are dried by the air drying process to control the moisture content at about 10%. The eluted and dried cut stems are transferred into a rotating drum, and under the condition of continuous rotation, 15% of the cut stem mass is sprayed with glycerin, and then taken out after 20 minutes of decompression and equilibrium diffusion at 800 mbar. Cut stem products that enhance the whiteness of cigarette ashes.

[0041] The cutting rate of cut stems obtained by the above method is about 17%. The shredded stem was used to make cigarette (2#) with shredded tobacco according to the ratio in the original formula, and compared with the original cigarette (1#), the results are as follows:

[0042] Sample serial number Ash whiteness Tuff Index 1# 96.2 6.1 2# 126.4 5.5

[0043] As can be seen from the above table, com...

Embodiment 3

[0045] Add 50°C warm water to the conventional expanded cut stems and filter them for immersion for 20 minutes. After repeating the dipping once, the cut stems are dried by air drying process to control the moisture content at about 9%. The eluted and dried cut stems are sent into the rotating drum, and under the condition of continuous rotation, 10% of the cut stem mass is sprayed with glycerin, and then taken out after 30 minutes of decompression and equilibrium diffusion at 600 mbar. Cut stem products that enhance the whiteness of cigarette ashes.

[0046] The cutting rate of cut stems obtained by the above method is about 16%. The shredded stem was used to make cigarette (2#) with shredded tobacco according to the ratio in the original formula, and compared with the original cigarette (1#), the results are as follows:

[0047] Sample serial number Ash whiteness Tuff Index 1# 96.2 6.1 2# 124.1 5.1

[0048] As can be seen from the above table,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com