Differential chain assembly line for bundling, loading and unloading

A technology of assembly line and differential chain, which is applied to the parts of strapping machinery, strapping materials, packaging, etc., and can solve problems such as downward bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

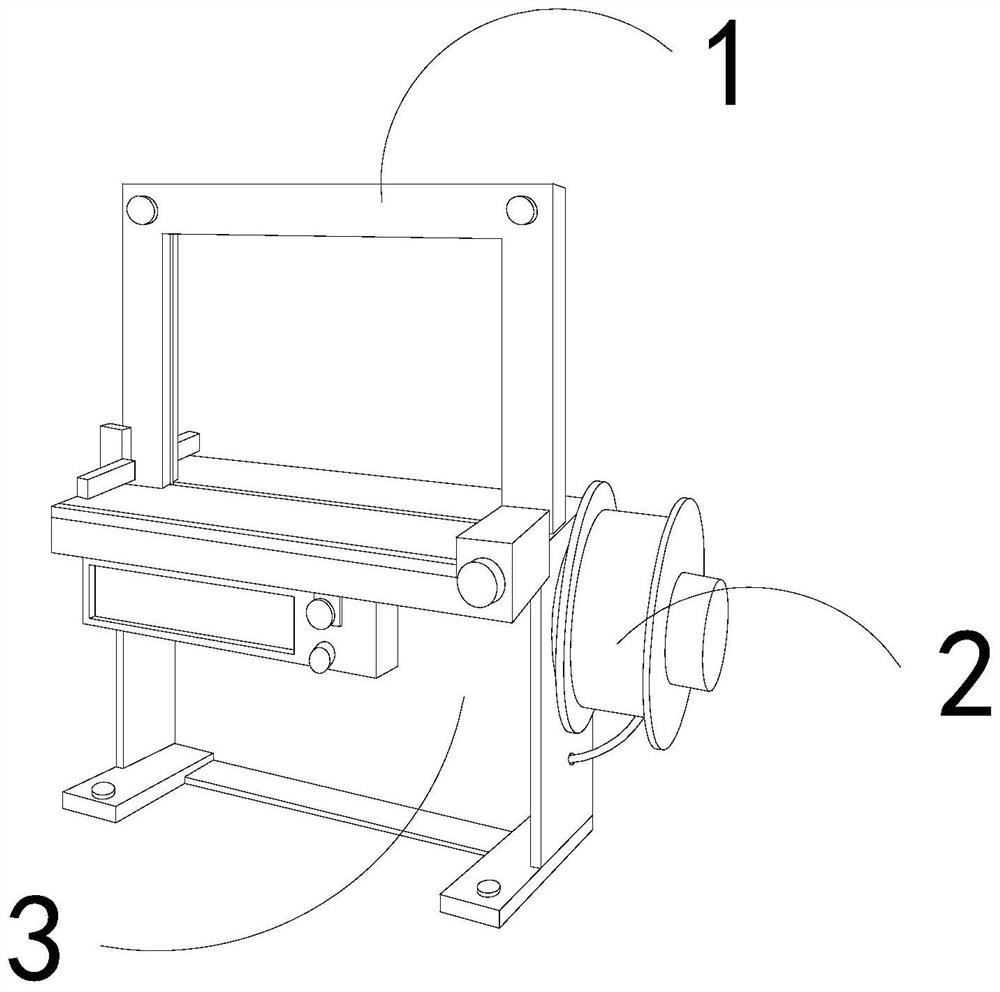

[0026] For example figure 1 -example Figure 5 Shown:

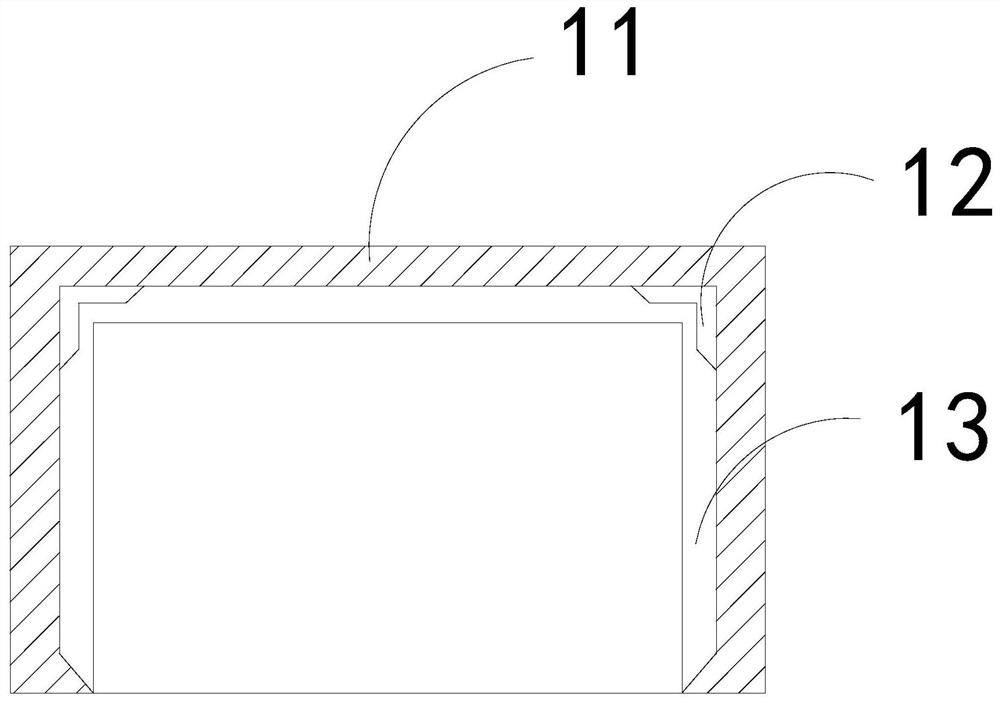

[0027] The present invention provides a differential chain assembly line for bundling and loading and unloading. The folding frame 1 is embedded in the upper end position of the strapping machine 3; the bending frame 1 includes a frame 11, a positioning mechanism 12, and a guide cavity 13, and the positioning mechanism 12 is embedded and connected with the inner side of the frame 11, and the guiding The cavity 13 and the frame 11 are an integral structure.

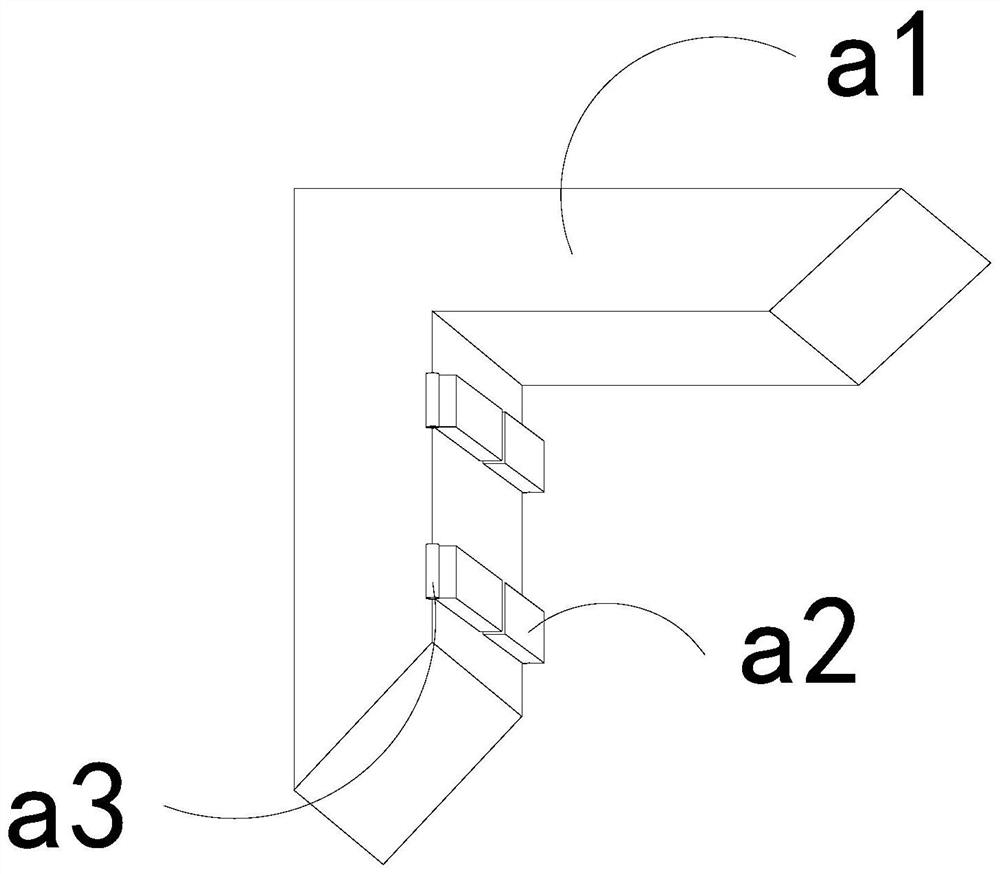

[0028] Wherein, the positioning mechanism 12 includes a plate body a1, a swing plate a2, and a connecting roller a3. The swing plate a2 is movably engaged with the plate body a1 through the connecting roller a3. There are four swing plates a2, and two One is a group of evenly distributed in parallel on the inner lower end of the plate body a1 , and the packing tape can be clamped by the tape collecting roller 2 .

[0029] Wherein, the connecting roller a3 includes...

Embodiment 2

[0034] For example Figure 6 -example Figure 8 Shown:

[0035] Wherein, the swing plate a2 includes an upper frame c1, a springback piece c2, and a shrinkage frame c3, the springback piece c2 is movably engaged with the upper frame c1, and the shrinkage frame c3 is installed on the springback piece c2 and the upper frame c1 Between the inner walls of the bag, the reverse thrust generated by the packaging belt on the resilient piece c2 can make the resilient piece c2 shrink upward along the upper frame c1, so that the packaging bag can smoothly pass between the surface of the object and the resilient piece c2.

[0036] Wherein, the resilient sheet c2 includes an elastic rod c21, a contact block c22, a bottom plate c23, and a receiving plate c24. connection, the bottom plate c23 and the receiving plate c24 are an integrated structure, and the contact blocks c22 are provided in five, and are evenly distributed in parallel on the bottom plate c23, and the contact block c22 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com