Center line marking device for end face of long-strip-shaped part

A scribing device and strip-shaped technology, applied in workshop equipment, manufacturing tools, etc., can solve the problems of inaccurate center line scribing and troublesome operation of the center scribing device, and achieve accurate center line scribing, convenient operation, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

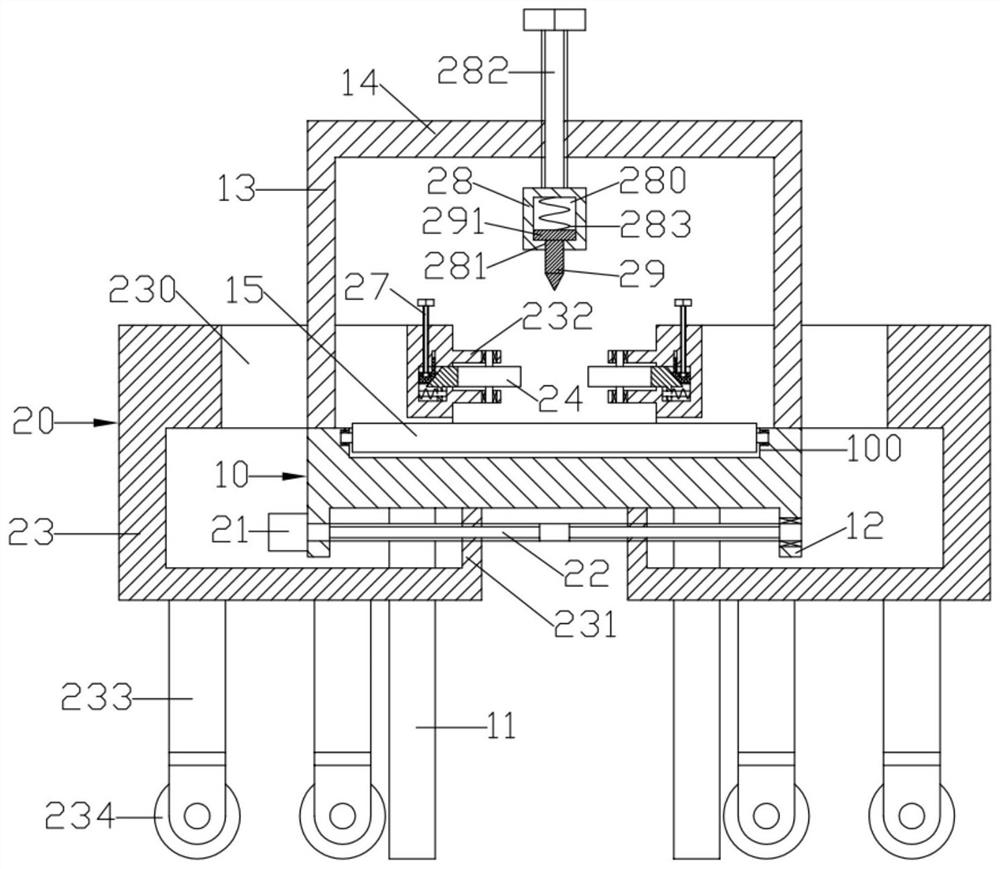

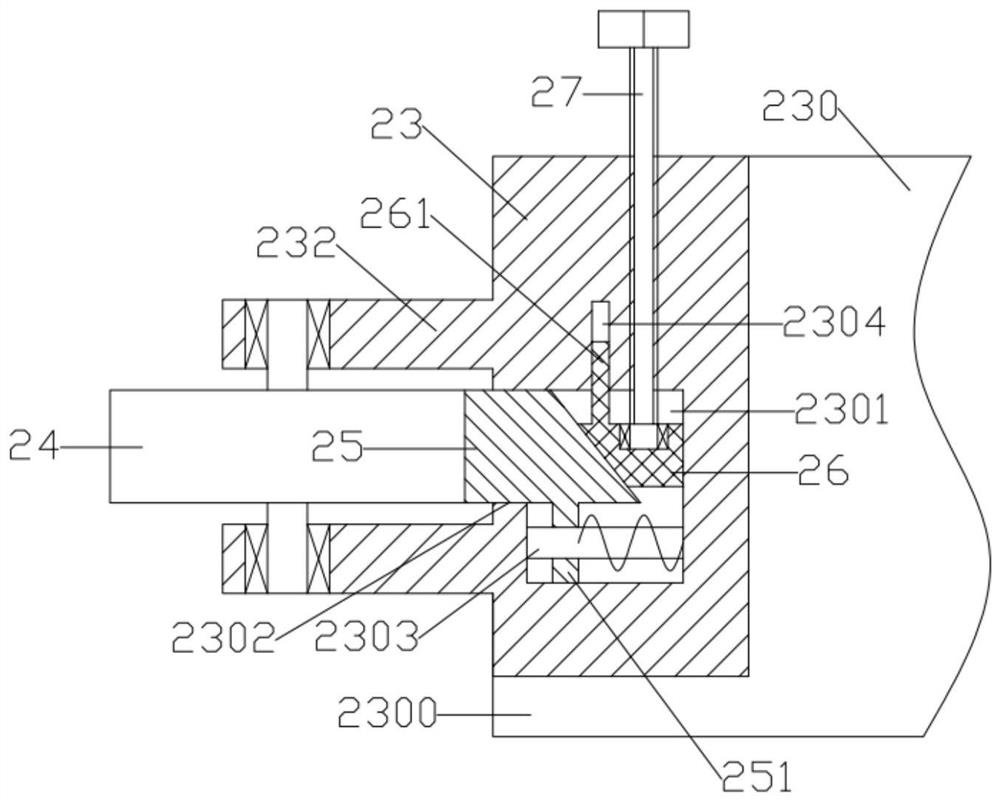

[0016] like figure 1 , figure 2 As shown, a centerline scribing device for the end face of a strip-shaped part includes a workbench 10 and a scribing device 20; a number of evenly distributed support feet 11 are arranged on the bottom surface of the workbench 10; the left end of the upper end surface of the workbench 10 The upper end of a pair of vertical connecting plates 13 is formed with a horizontal support plate 14; the lower end surface of the horizontal support plate 14 is vertically lifted with a sliding pen 29; the marking device 20 includes a The left and right limit seats 23 are symmetrically arranged on the left and right sides; a pair of left and right limit seats 23 are arranged on the workbench 10 for left and right movement and are set away from or approached synchronously; The upper part of the left and right limiting seat 23 is formed with a left and right moving avoidance groove 230 that cooperates with the vertical connecting plate 13; a pair of left and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap