An adaptive method of presser foot

A self-adaptive, presser foot technology, applied in textiles and papermaking, embroidery machines, feeding devices, etc., can solve quality problems, time-consuming and labor-consuming problems, and achieve the effect of avoiding quality problems and improving adjustment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

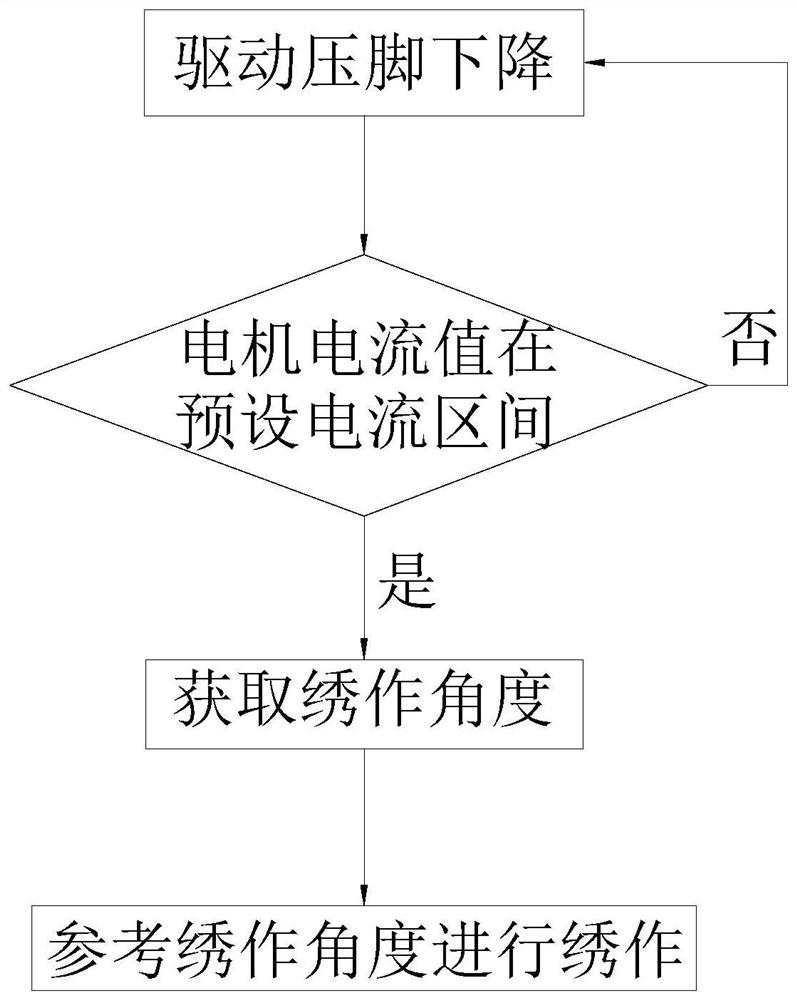

[0029] like figure 1 As shown, this embodiment discloses a presser foot self-adaptive method, which includes the following steps:

[0030] S1. The presser foot is driven by the closed-loop motor, and the current value of the motor is obtained in real time. The closed-loop motor rotates and the presser foot drops. When the presser foot touches the fabric and encounters resistance, the current of the closed-loop motor will increase, so the closed-loop motor can be detected by detecting the closed-loop motor. The current value is used to detect whether the presser foot effectively touches the fabric.

[0031] S2. Determine whether the presser foot is effectively in contact with the fabric according to the current motor current value. When the motor current value is too large, it means that the presser foot contacts the fabric too tightly, and when the motor current value is too small, it means that the presser foot does not completely contact the fabric, so here, when the motor ...

Embodiment 2

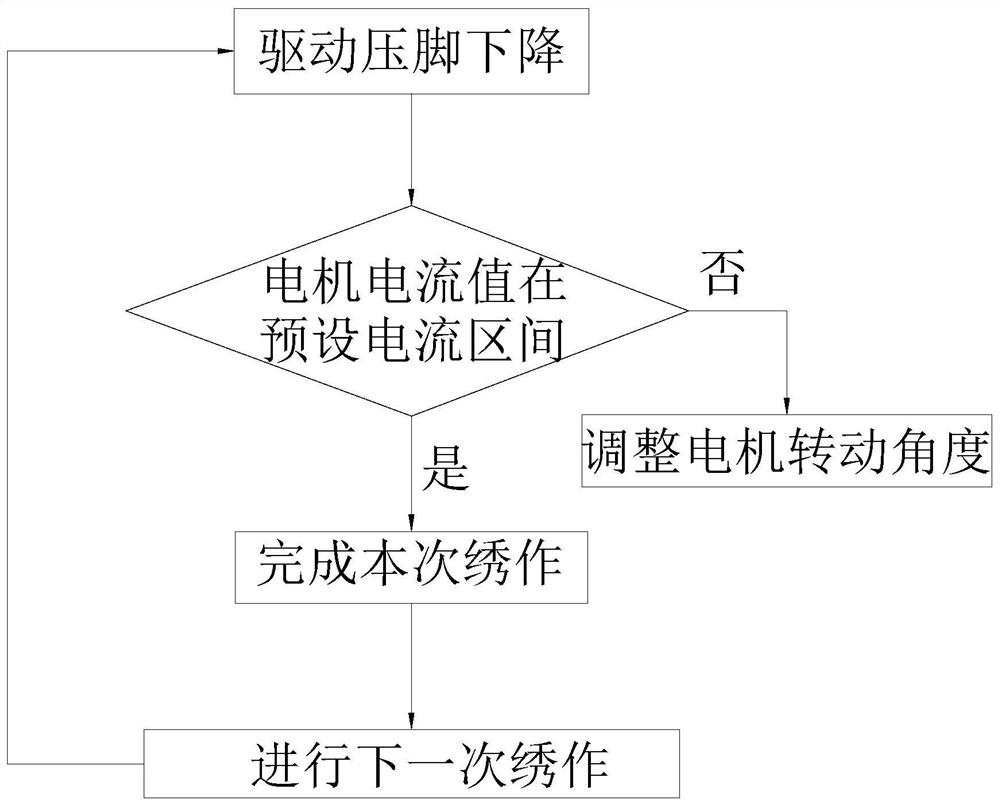

[0041] like figure 2 As shown, this embodiment is similar to Embodiment 1, the difference is that this embodiment belongs to the intelligent mode, which can be used for embroidering fabrics with different thicknesses, and is automatically adjusted according to the fabric thickness in real time during the embroidery process. Specifically:

[0042] In the smart mode, steps S1-S3 are:

[0043] S12. Drive the presser foot down, and obtain the motor current value in real time;

[0044] S22. Determine whether the motor current value is within the preset current range, if so, carry out this embroidery, otherwise adjust the motor rotation angle to maintain the motor current value within the preset current range;

[0045] S32. Repeat steps S12 and S22 in the subsequent embroidery process.

[0046] Compared with the first embodiment, this embodiment has a higher degree of intelligence, and is more adaptable to fabrics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com