Pile gripper of vibrating pile hammer with internal supporting type clamping structure and using method of pile gripper

An inner support type and clamping oil cylinder technology is applied in the field of building foundation engineering, which can solve the problems of the clamping device not being able to sink into the ground, and the pile top being driven into the depths of the ground, so as to achieve the effect of being beneficial to the pile sinking operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Next, the technical solutions adopted in the present invention will be further described through the embodiments and accompanying drawings, so as to help those skilled in the art better understand the present invention.

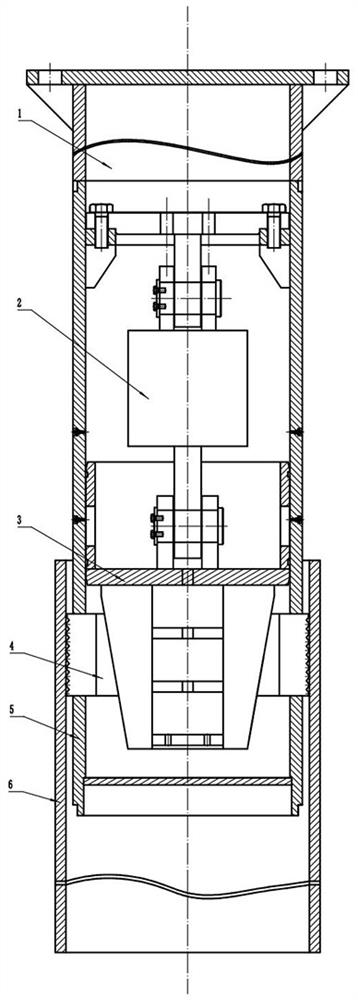

[0024] The present invention provides an inner support type pile clamping structure, see figure 1 , including a sleeve 5; a clamping cylinder 2 installed in the sleeve 5; several wedge-shaped push blocks 3, the wedge-shaped push blocks 3 are connected to the bottom of the clamping cylinder 2, and the cylinder 2 drives the wedge-shaped The pushing block 3 moves up and down along the axial direction of the sleeve 5; several wedge-shaped clamping blocks 4, the position of the wedge-shaped clamping block 4 matches with the wedge-shaped pushing block 3, and the mating surface is a slope, and the wedge-shaped pushing block 3 Moving up and down in the axial direction causes the wedge-shaped clamping block 4 to move radially along the sleeve 5 , and the wedge-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com