Differential pressure sectional plugging process for bittern natural gas waste well

A technology for natural gas and abandoned wells. It is applied in the direction of sealing/isolation, wellbore/well components, and drilling compositions. It can solve the problems of plugging construction failure, formation fracture development, collapse, etc., and achieve good resistance to water loss. Good performance and fluidity, save cement slurry, and reduce self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

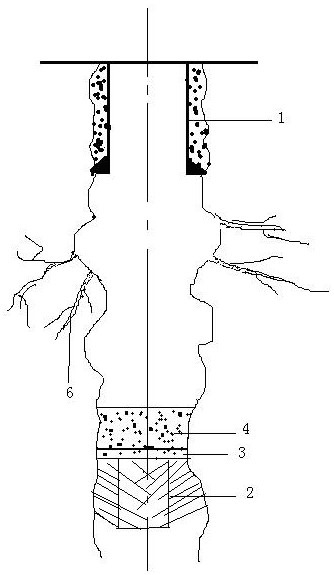

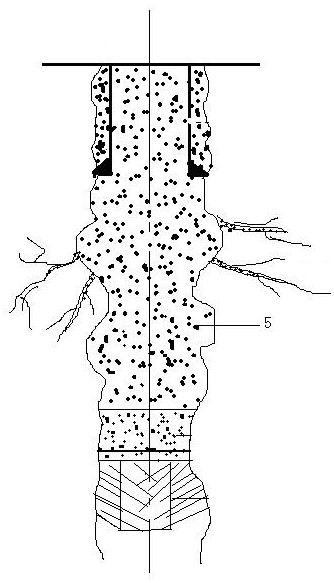

[0013] Below in conjunction with accompanying drawing, the present invention is described in further detail.

[0014] The pressure difference staged plugging process of the brine natural gas waste well of this embodiment, such as figure 1 As shown, it includes the following steps: A) Install casing 1 and blowout preventer at the wellhead, and drill through the well; B) Conduct engineering logging: use methods such as borehole diameter, natural gamma ray and acoustic wave time difference to obtain the wellbore diameter and formation Fracture development data; C) Use the drilling tool to push the tough plug: the rubber plug 2 is pushed to a certain distance below the bottom formation fracture 6 for positioning, the outer diameter of the rubber plug 2 is larger than the inner diameter of the wellbore at the location, and then the drilling tool is slightly lifted; D) Inject the first front-section cement slurry 3 with a liquid column length of 10 meters above the rubber plug 2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com