A combined thrust vectoring nozzle system and projectile with the system

A thrust vectoring, combined technology, applied in the direction of self-propelled missiles, jet propulsion devices, offensive equipment, etc., can solve the problems of low reliability of thrust vectoring devices, increased engine weight, increased engine weight, etc., to enhance the anti-ablation ability. , reduce friction, reduce the effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

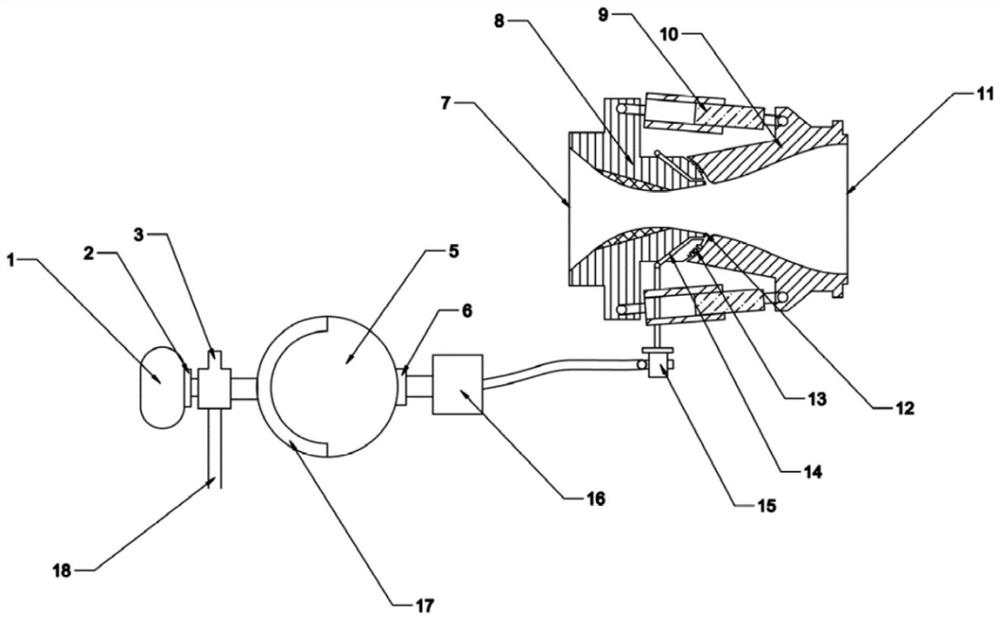

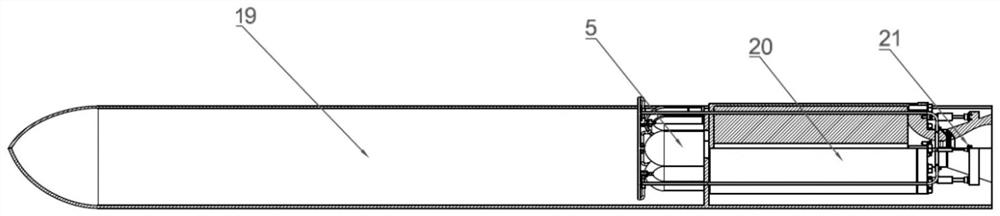

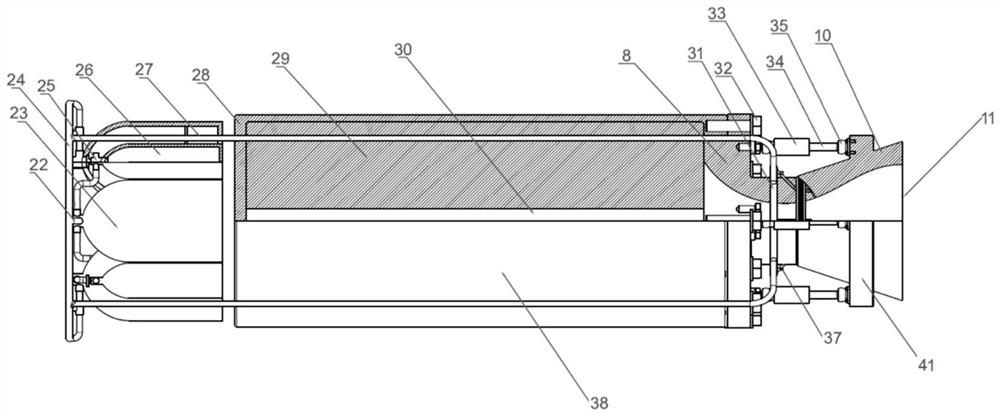

[0043] see Figure 1-Figure 3 , the invention provides a combined thrust vectoring nozzle system, comprising a supersonic separation line swinging nozzle (such as Figure 4-Figure 5 shown), liquid secondary injection system (such as Figure 6-Figure 8 shown) and the control system (such as Figure 9-Figure 12 shown).

[0044] The control system (such as Figure 9-Figure 12 shown) including the comprehensive lateral force control system (such as Figure 9 shown), the secondary injection control system (such as Figure 10 shown) (including electromagnetic flowmeter controller, liquid secondary injection controller, flow signal processing module), and supersonic separation line swing nozzle control system (such as Figure 11 shown).

[0045] The invention combines the supersonic separation line swing nozzle with the liquid secondary injection system, effectively increasing the reliability of the supersonic separation line swing nozzle. The present invention simultaneously ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com