Indoor photoelastic lining model multi-axis loading experiment system and multi-axis loading mechanism

A shaft loading and shaft loading technology, which is applied in the direction of strength characteristics, using stable tension/pressure testing material strength, measuring devices, etc., can solve the problem of multi-directional loading, large limitations, and single loading method in geotechnical engineering. problem, to achieve a comprehensive and reliable experimental loading operation, to meet the effect of adaptation and comprehensive experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

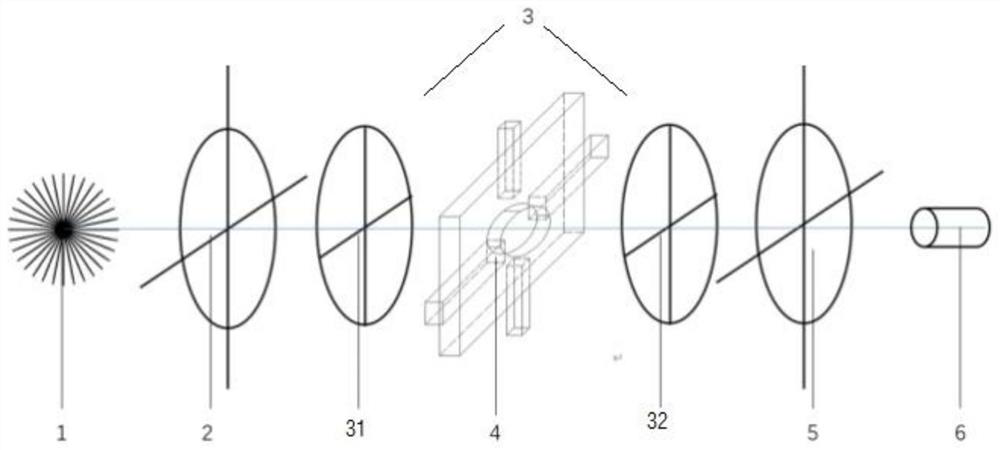

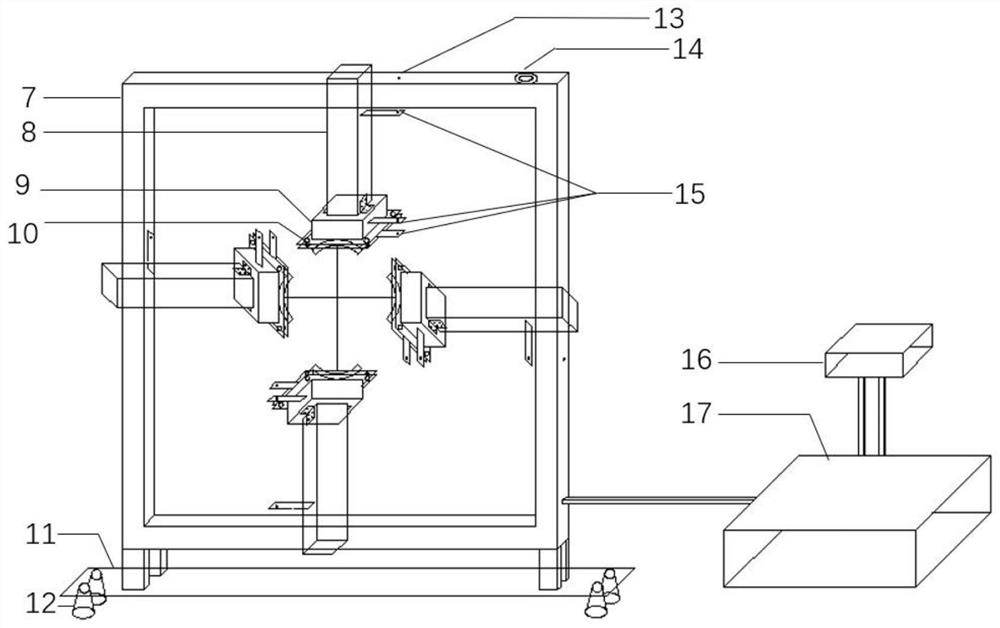

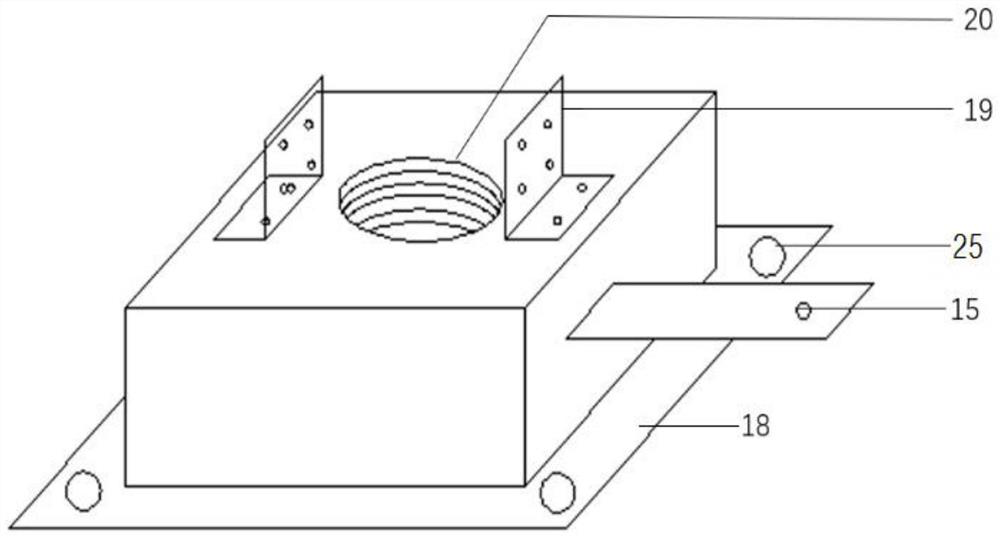

[0032] The embodiment of the present application provides an indoor photoelastic lining model multi-axial loading experiment system and a multi-axial loading mechanism to solve the problem of the single loading method and too many limitations in the photoelastic experiment in the prior art, which cannot meet the multi-directional loading of geotechnical engineering Technical issues required by the experiments.

[0033] In order to better understand the above technical solutions, the above technical solutions will be described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the embodiments of the present invention and the specific features in the embodiments are detailed descriptions of the technical solutions of the present application. , rather than limiting the technical solutions of the present application, the embodiments of the present application and the technical features in the embodiments c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com