Long-focal-length high-uniformity vision detection system and manufacturing method thereof

A visual inspection and uniformity technology, which is applied in installation, optics, instruments, etc., can solve the problems of small light transmission of the inspection lens, poor close-range image quality, and complex structure, so as to improve the illumination and field area, and balance the optical focus Degree, improve the effect of primary chromatic aberration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

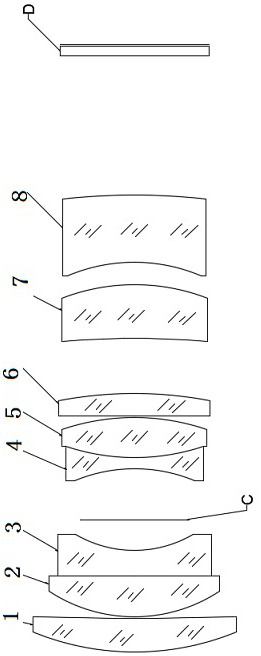

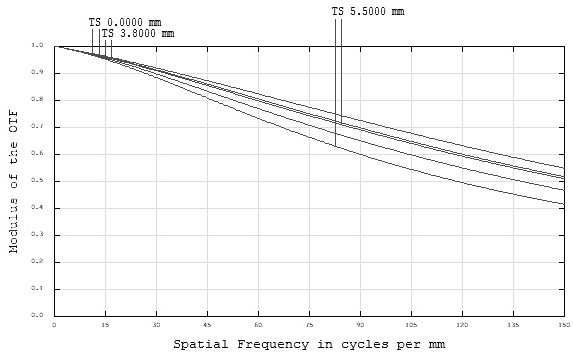

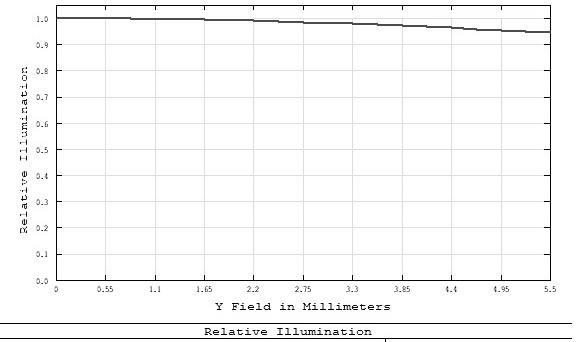

[0029] Such as Figure 1~4 As shown, a long focal length and high uniformity visual inspection system, the optical system of the lens is sequentially provided with a front lens group A, a diaphragm, a rear lens group B, and a flat protective glass D along the incident direction of light from left to right, The front lens group A includes a crescent-shaped lens A1 with a positive refractive power, a crescent-shaped lens A2 with a positive refractive power, and a crescent-shaped lens A3 with a negative refractive power arranged in sequence. The rear lens group B sequentially includes a crescent-shaped lens B1 with a negative power, a biconvex lens B2 with a positive power, a bi-convex lens B3 with a positive power, and a crescent lens with a positive power. Shaped lens B4, crescent-shaped lens B5 with negative power, flat protective gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com