Particulate burnable poison reactivity control method, burnable poison plate and fuel rod

A reactivity control and reactivity technology, applied in the control of nuclear reactions, reactor fuel materials, reactors, etc., to achieve the effects of facilitating control, improving flexibility and operational safety, and reducing burnable poison residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The invention provides a method for controlling the reactivity of particulate combustible poisons, comprising:

[0032] By setting the residual reactivity and lifetime at the beginning of the core life, and inputting the residual reactivity and lifetime at the beginning of the core life into the core reactivity and burnup change model, the parameters of the particulate burnable poison are obtained; the particulate burnable poison The parameters include particle type, particle diameter, particle volume fraction, particle doping ratio, and particle porosity; based on the particle burnable poison parameters, the target particle burnable poison is selected to add to the core.

[0033] Among them, the particulate burnable poison refers to the burnable poison existing in the form of particles. Compared with the conventional uniformly distributed form of burnable poison, the burnable poison in the form of particles can increase the space self-shielding effect of the burnable p...

Embodiment 2

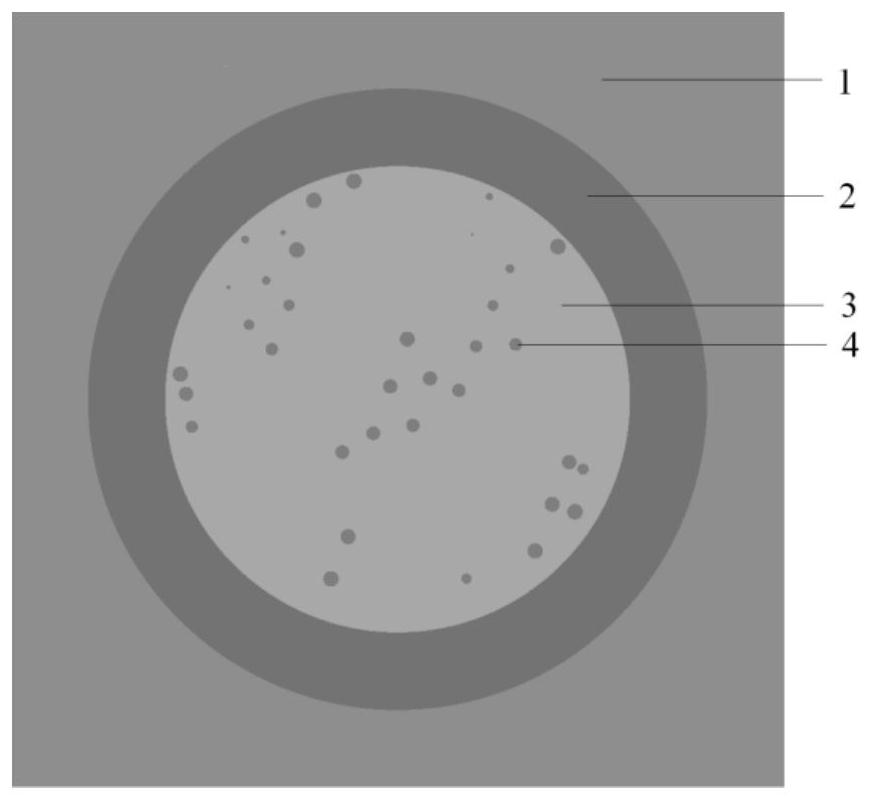

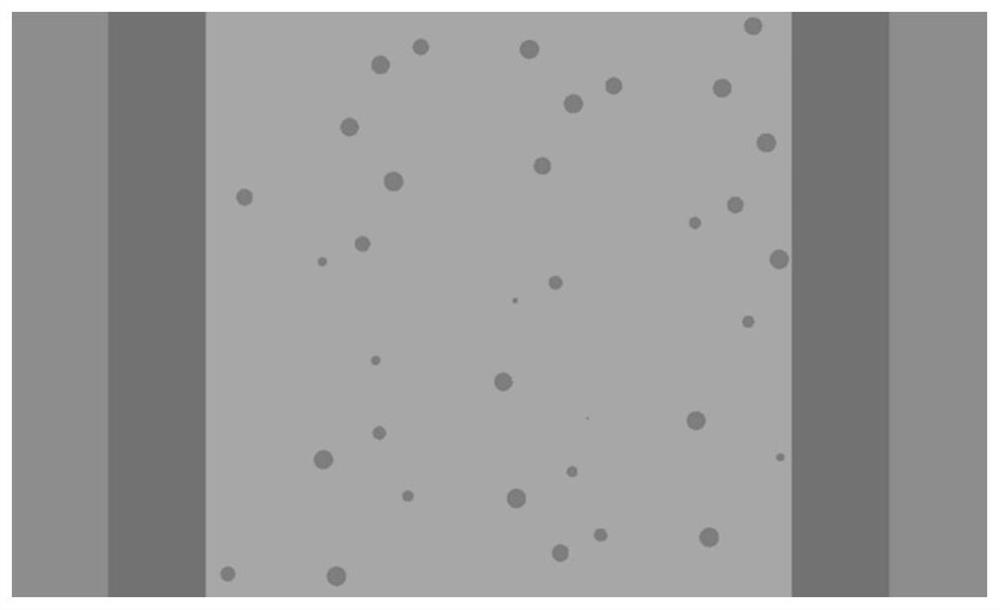

[0038] Such as figure 1 and figure 2 As shown, the target particle combustible poison in the form of particles is uniformly and randomly dispersed in the fuel matrix. According to the residual reactivity at the beginning of the core life and the length of life, the fuel enrichment degree of the matrix in this embodiment is 4.45%, and the particle type is B 4 C. The particle diameter is 100 μm, the particle volume fraction is 5%, the particle doping rate and particle porosity are 0% to realize the control of reactivity, and the neutron absorption of the particle is gradually released through the space self-shielding effect of the particle combustible poison , the poison burnup rate is effectively controlled, so that the reactivity of the core during its entire life is effectively controlled.

[0039] Specifically, dispersing the target particle burnable poison in the fuel matrix does not occupy the position of the fuel cell, and at the same time, it does not cause serious pow...

Embodiment 3

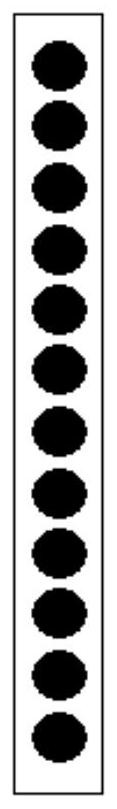

[0041] Such as image 3As shown, the target particle burnable poison can not only be dispersed in the fuel matrix, but also can be used to form a separate burnable poison to form burnable poison pellets, and then use the burnable poison pellets to form a burnable poison plate. In this embodiment, Er2O3 pellets are used in the separated burnable poison plate. The diameter of the burnable poison pellets is 500 μm, the particle volume fraction is 45%, and the particle doping rate is 20%. The base material of the burnable poison plate in this embodiment is doped with zirconium, and the particle porosity is 0%.

[0042] Specifically, the separated burnable poison composed of target particle burnable poison not only helps to increase the absorption area of the burnable poison, but also increases the burnup rate of the poison so as to reduce the residual poison at the end of life, and facilitates the division of the poison, which is beneficial to the residual reaction of the reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com