Dustproof device for building construction socket

A technology for building construction and dust-proof devices, which is applied in the direction of coupling devices, parts of connecting devices, bases/shells, etc., which can solve the inconvenience of operation, increase the difficulty of using dust-proof devices, and the lack of dust-proof protection and sealing of sockets, etc. problems, to achieve the effect of strengthening the dustproof function and sealing effect, increasing flexibility and practicality, and improving the effect of dustproof protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

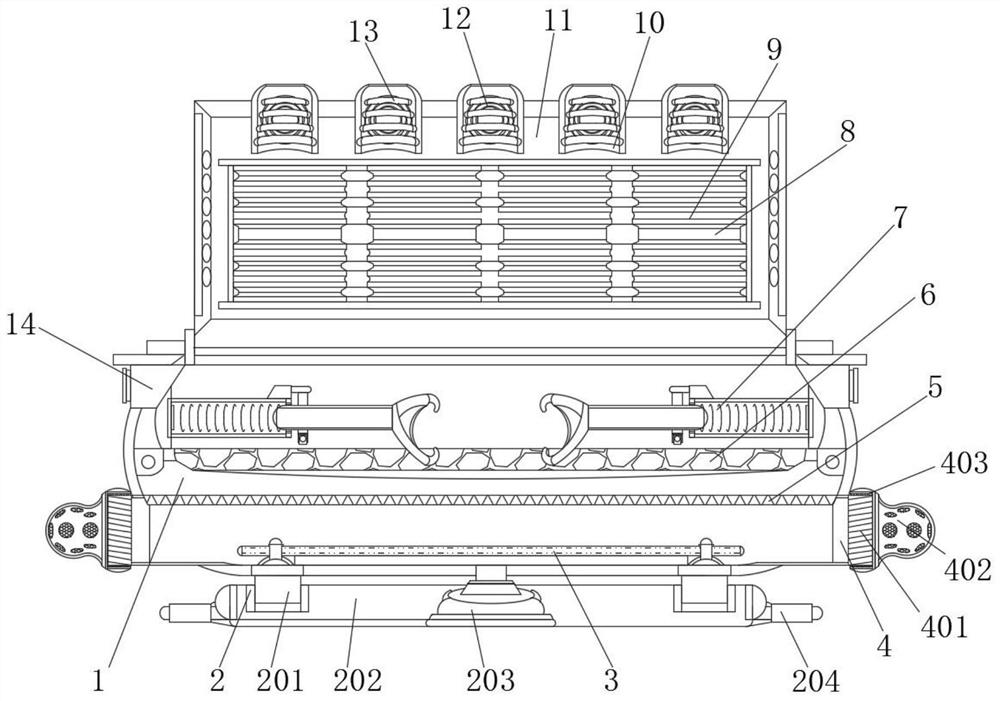

[0032] Example 1, such as Figure 1-4 As shown, when the socket is fixed in the protection groove 1, the power cord inserted into the connection can be connected, and then the movable cover 11 is closed, during which when the movable cover 11 is pulled down, the power cord can be placed in the specified position and arc The curved clips 13 are attached to each other, so that after the curved clips 13 are attached to the power cord, as the curved clips 13 descend in the guide groove 15 and are extruded by the compression spring, the curved clips of different widths can be used. The clamping part of the plate 13 presses and fits different types of power cords, so that the reserved space for the power cords of the semi-arc installation compartment 10 can be automatically adapted to reduce the penetration space of the dust-proof device and enhance the sealing performance of the device.

Embodiment 2

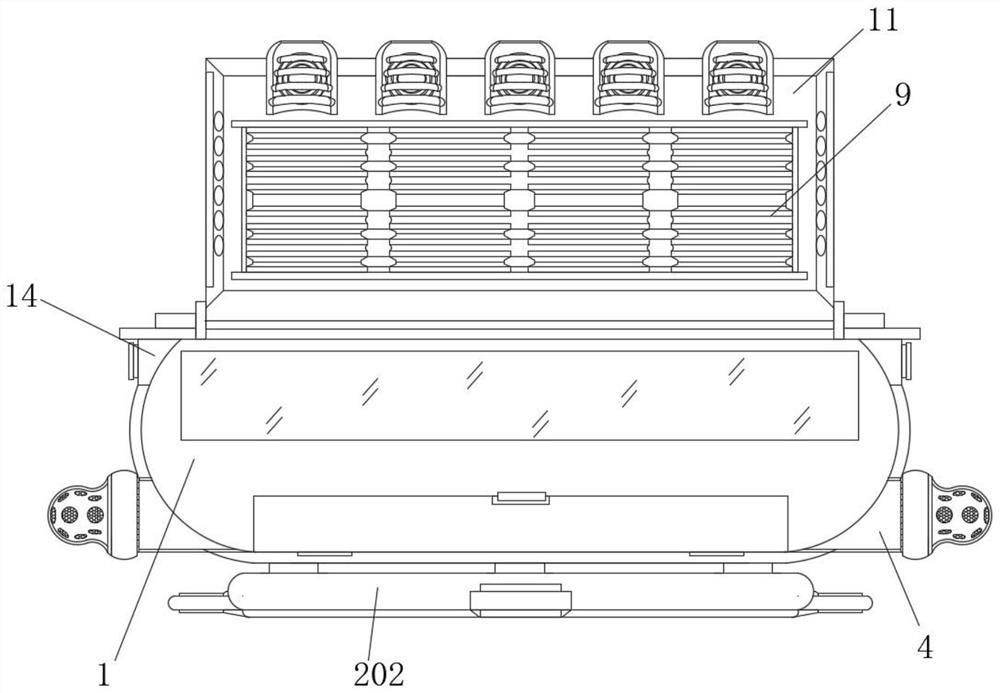

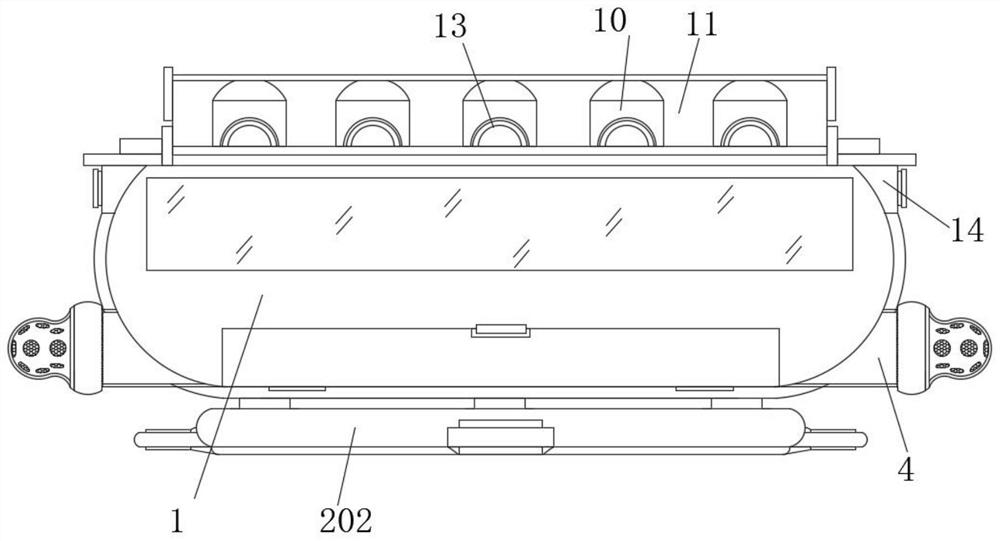

[0033] Example 2, such as Figure 5 As shown, when the device needs to be fixed, the installation and cooperation of the locating member 204 can be used to position the device in a specified position. At this time, the connection and cooperation between the rotating suction cup 203 and the slider 201 and the protective groove 1 enable the device to be fixed on the rotating suction cup 203. And the rotary guide structure of the annular chute 2 can move, so that after the device is fixed, the angle of the power cord can also be changed at any time, increasing the flexibility of the device and the convenience of use.

[0034] Working principle: When using the device, first open the movable cover 11 to open the inside of the protective groove 1, and then pull the inner sleeve 702 to shrink and move with the cooperation of the outer sleeve 7, and drive the spring 701 to compress, at this time the protection can be achieved. Put the socket into the clamping part of the fixed claw 704,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com