Magnetic control lock, unlocking device and lock cylinder

An unlocking device and magnetically controlled lock technology, applied in the field of locks, can solve the problems of being unable to be used portablely, low anti-theft performance, low anti-theft security, etc. The realization method can be flexibly designed, the anti-theft safety performance can be improved, and the implementation methods are flexible and diverse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

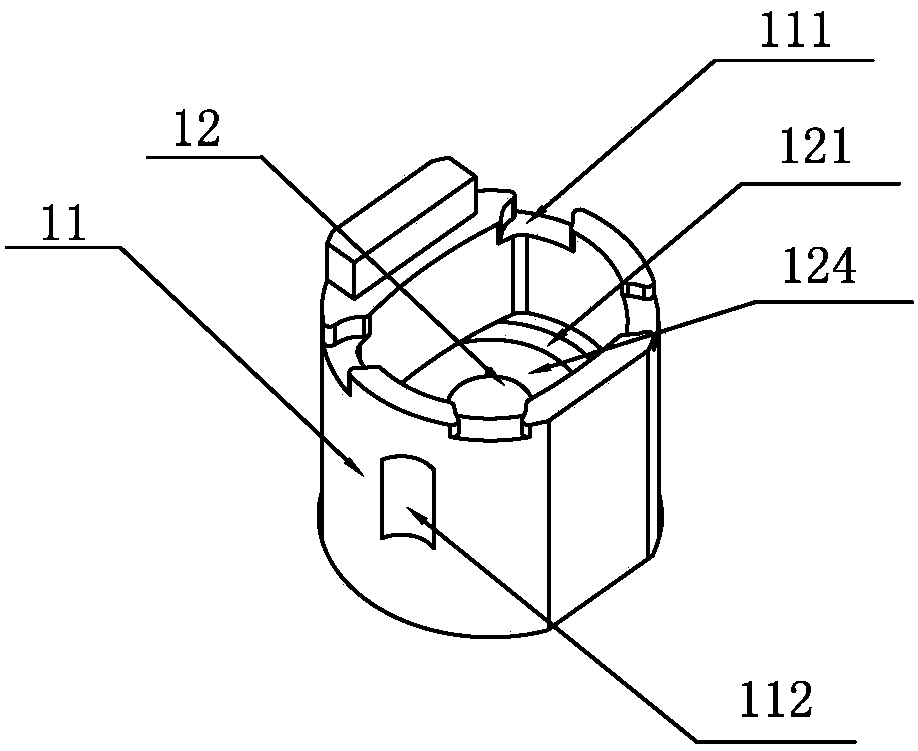

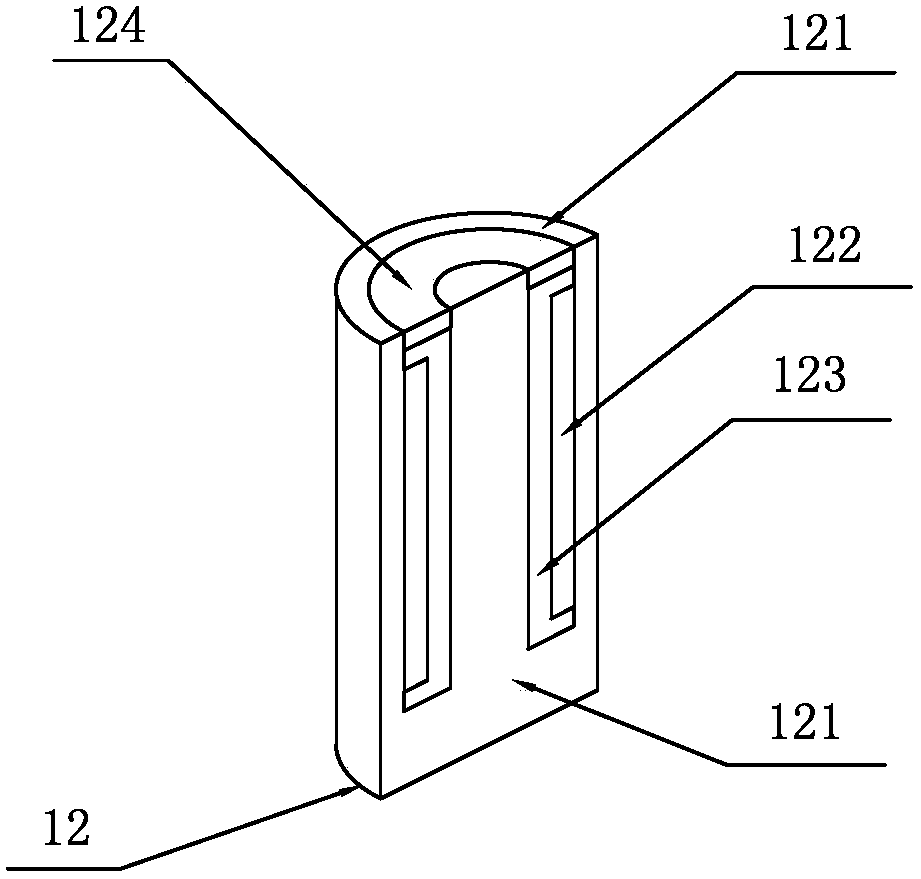

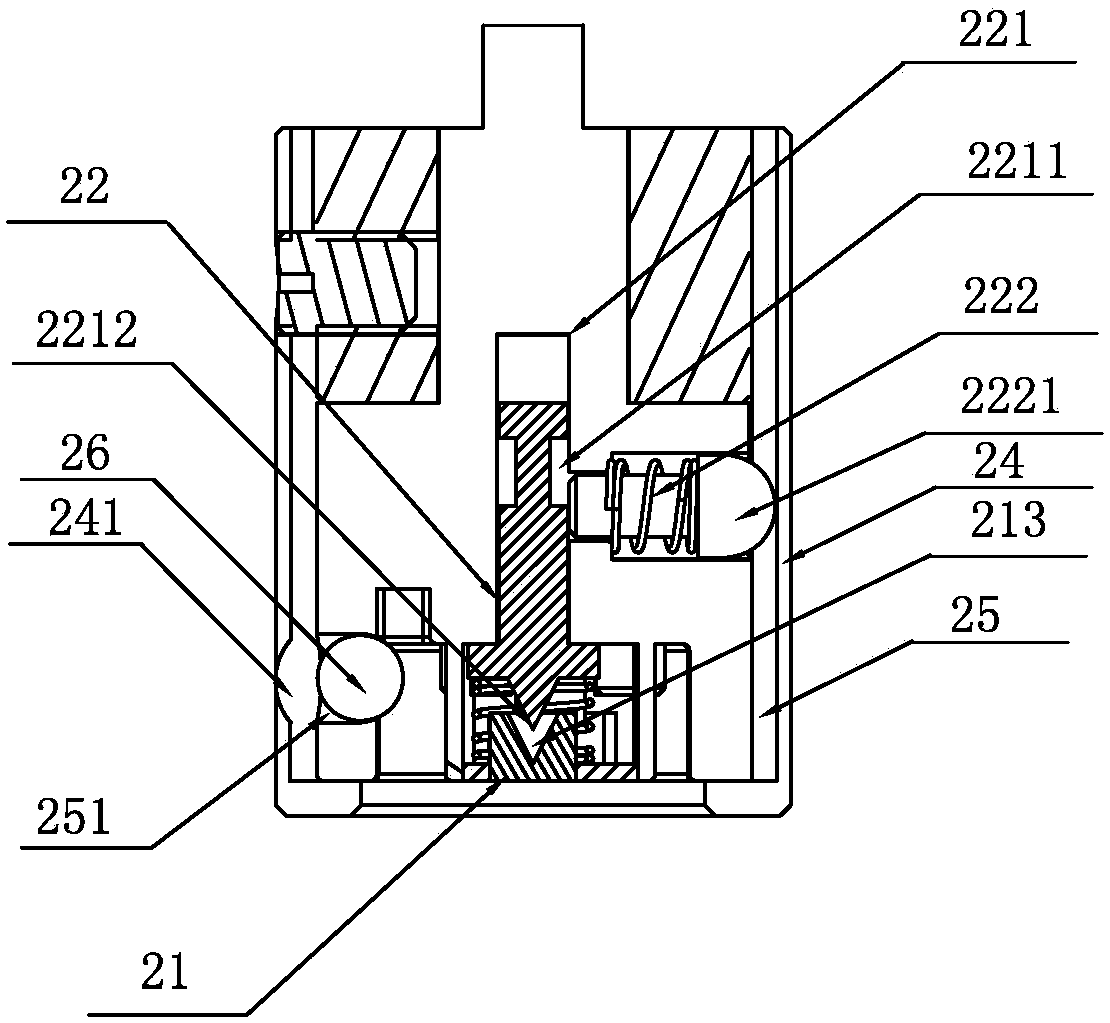

[0083] Refer to the attached Figure 7 And attached Figure 8 shown, among them, attached Figure 7 It is a schematic diagram of the cross-sectional structure of the first embodiment of the present invention in the locked state, with Figure 8 It is a schematic diagram of the cross-sectional structure of the first embodiment of the present invention in the unlocked state. As shown in the figure, in the first embodiment, the electromagnetic device 12 adopts the figure 2 The same implementation method as in , will not be repeated here. The second magnetically conductive part 21 in the lock core 2 adopts the same realization method as the first magnetically conductive part 121, that is, the second magnetically conductive part 21 is a hollow first magnetically conductive cylinder with one end closed and one end open and placed on the It is composed of a second magnetically permeable cylinder in the middle of the hollow first magnetically permeable cylinder, one end of the seco...

Embodiment 2

[0088] Refer to the attached Figure 9 And attached Figure 10 shown, among them, attached Figure 9 It is a schematic diagram of the cross-sectional structure of the second embodiment of the present invention under the locked state, with Figure 10It is a schematic cross-sectional structure diagram of the second embodiment of the present invention in an unlocked state. As shown in the figure, in the second embodiment, the first magnetically conductive member 121 is composed of an L-shaped magnetically conductive shell and a magnetically conductive column, wherein, The magnetically permeable column is arranged flush with the vertical section of the L-shaped magnetically permeable housing, and one end of the magnetically permeable column is connected to the horizontal section of the L-shaped magnetically permeable housing, and the coil 122 is wound on the magnetically permeable column.

[0089] The second magnetically permeable component 21 is divided into two parts, a first ...

Embodiment 3

[0093] Refer to the attached Figure 11 And attached Figure 12 shown, among them, attached Figure 11 It is a schematic diagram of the cross-sectional structure of the third embodiment of the present invention in the locked state, with Figure 12 It is a schematic cross-sectional structure diagram of the third embodiment of the present invention in an unlocked state. As shown in the figure, in the third embodiment, the first magnetically conductive member 121 is a hollow cylinder with one end closed and one end open, and the coil 122 is wound around the sleeve connected to the closed end of the first magnetic permeable component 121 . The second magnetically permeable component 21 is divided into two parts, the two parts are set independently, and one end of the two parts can be aligned with the first magnetically permeable component 121 respectively.

[0094] The difference from the previous two embodiments is that in the first embodiment and the second embodiment, the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com