Horizontal flapping wing low-altitude aircraft

A low-altitude aircraft, flat shooting technology, applied in the field of aircraft, can solve problems such as limited application scope and the need for taxiing distance on the take-off runway.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

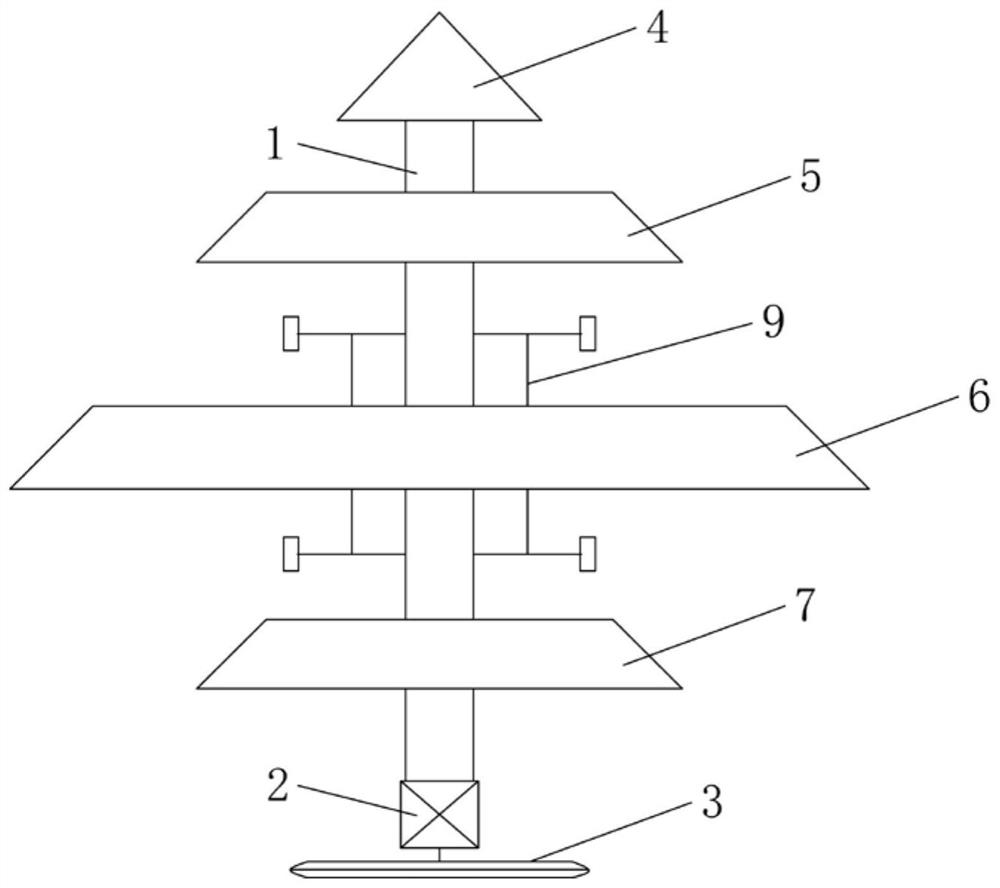

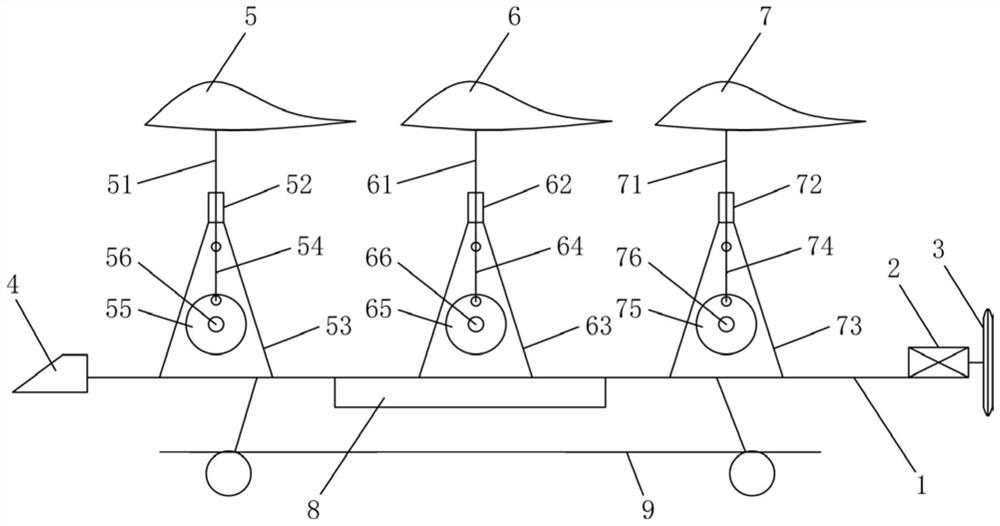

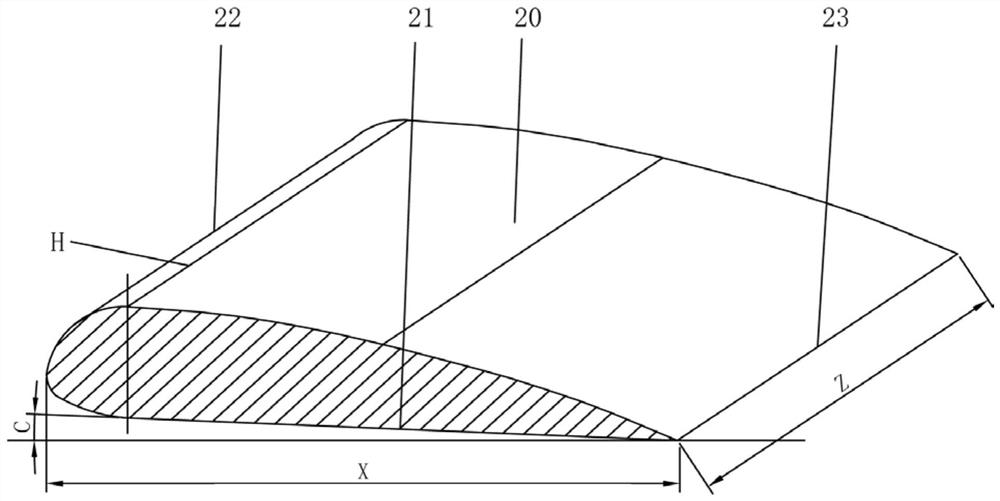

[0022] like figure 1 As shown, a kind of flat flap wing low-altitude aircraft of the present invention comprises frame 1, and frame 1 front end is provided with nose 4, and frame 1 tail end is provided with propulsion device, is provided with between nose 4 and propulsion device successively. The first flying unit, the second flying unit and the third flying unit, the second flying unit is set at the center between the first flying unit and the third flying unit, and is set at the center of gravity of the frame 1, on the frame 1 A control circuit 8 is provided, and the first flying unit, the second flying unit and the third flying unit are respectively controlled by the control circuit 8, and the first flying unit and the third flying unit move up and down synchronously, and alternate up and down with the second flying unit . The ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com