Dielectric waveguide filter

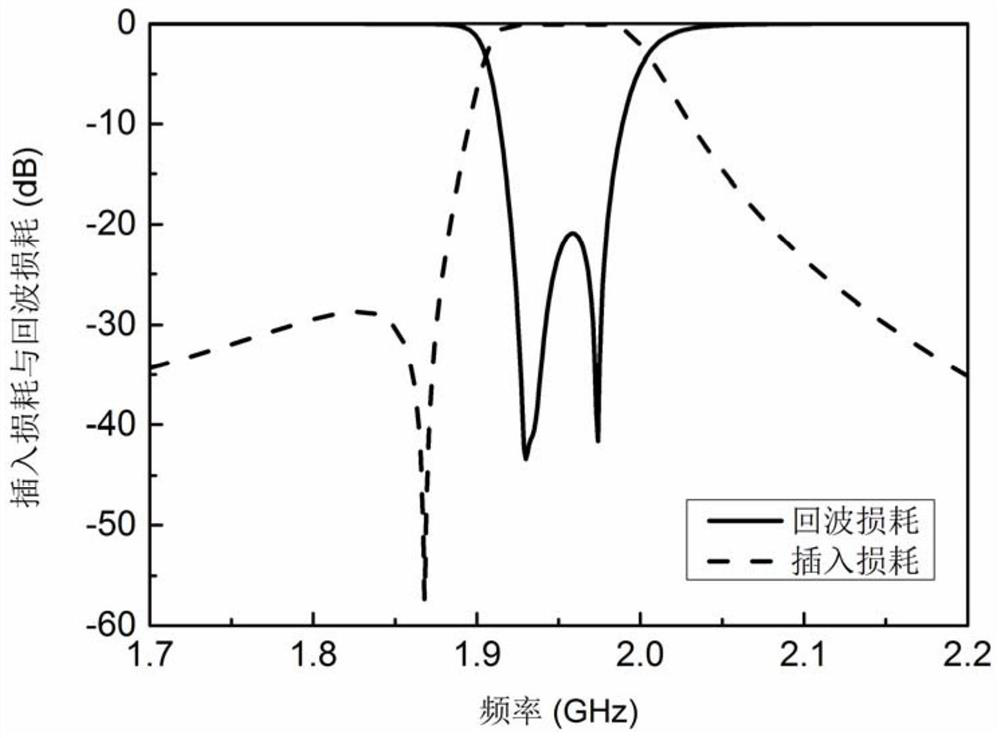

A dielectric waveguide and filter technology, which is applied in the field of communication equipment components, can solve the problems affecting the selectivity of ceramic dielectric filters and the difficulty of adding negative coupling structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

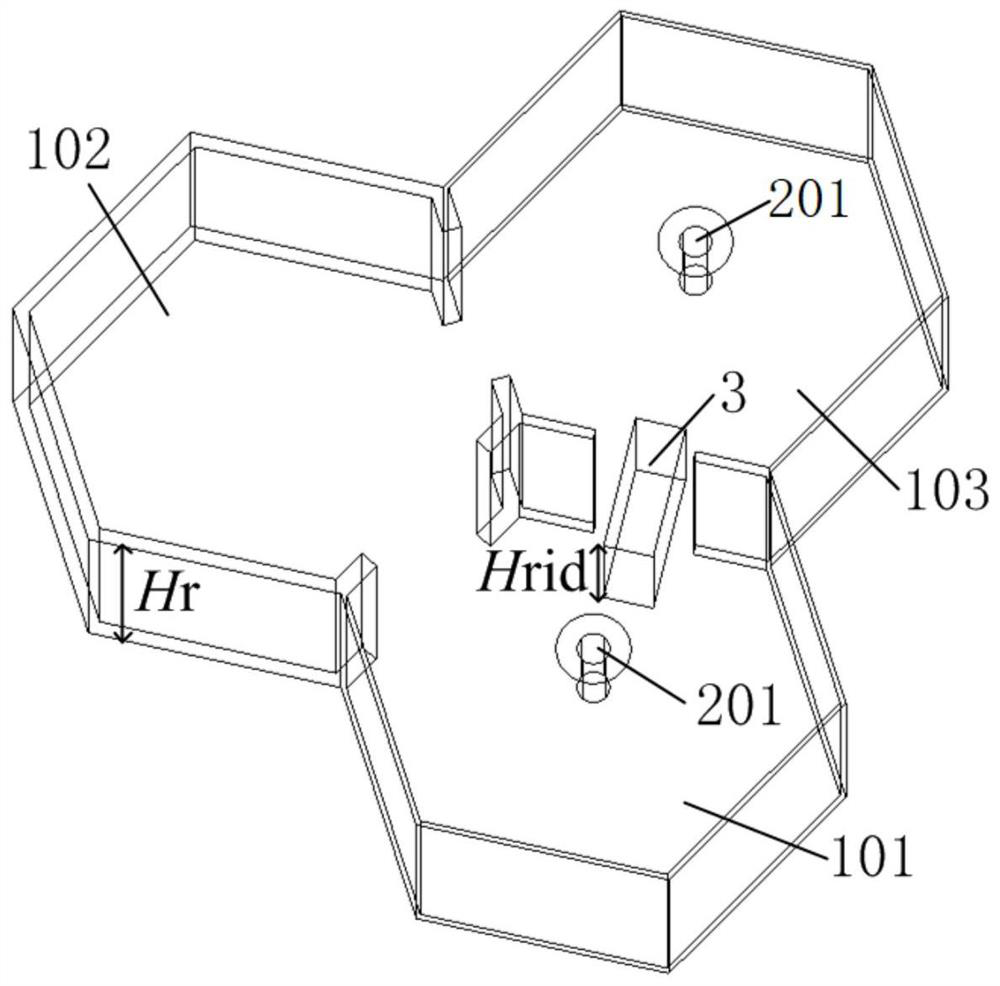

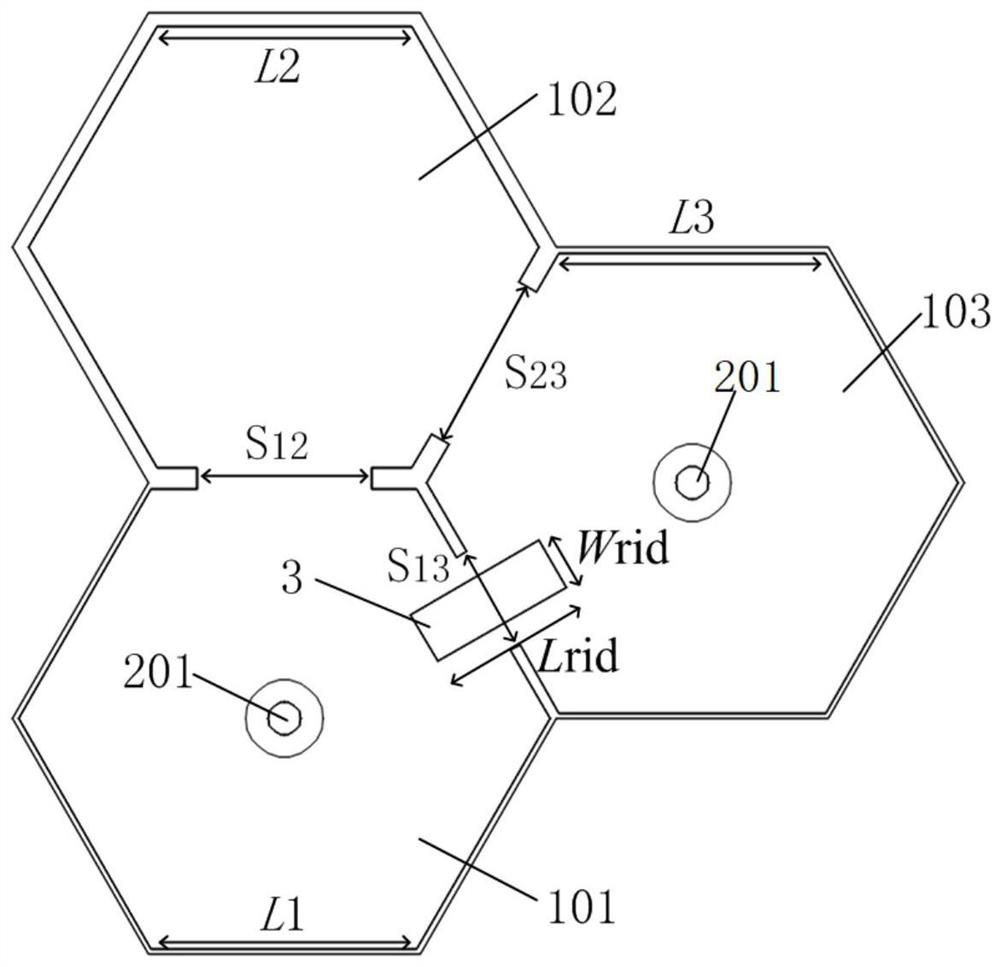

[0030] This embodiment provides a dielectric waveguide filter, such as figure 1 and figure 2 As shown, it includes three interconnected dielectric waveguide resonators and metallized slots 3 .

[0031] Wherein, the metallized groove is straddled on the interface between two adjacent dielectric waveguide resonators; the two adjacent dielectric waveguide resonators are connected through the metallized groove to realize negative coupling. The dielectric waveguide filter body is made of ceramic material. The three dielectric waveguide resonators are a first dielectric waveguide resonator 101 , a second dielectric waveguide resonator 102 and a third dielectric waveguide resonator 103 . The metallization groove 3 is arranged between the first dielectric waveguide resonant cavity 101 and the third dielectric waveguide resonant cavity 103 .

[0032] The metallized groove is arranged across the interface between two adjacent dielectric waveguide resonant cavities and connects the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com