Lead support frame

A support frame and wire technology, used in overhead installation, overhead line/cable equipment, electrical components, etc., can solve problems such as electric shock risk, reduction of wire sag height, safety hazards, etc., to reduce workload and solve electric shock risks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

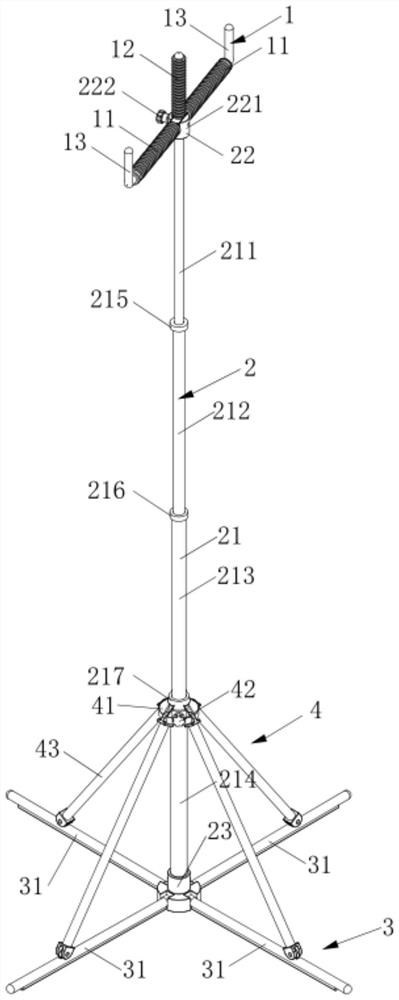

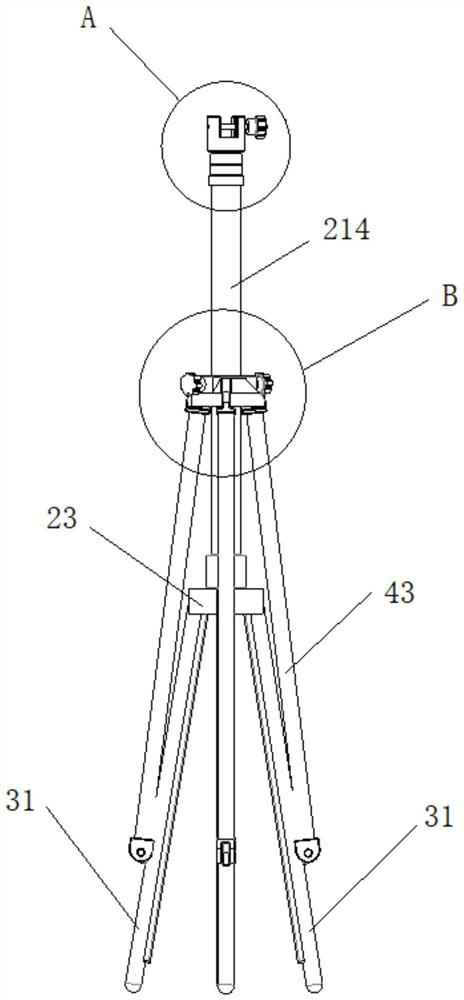

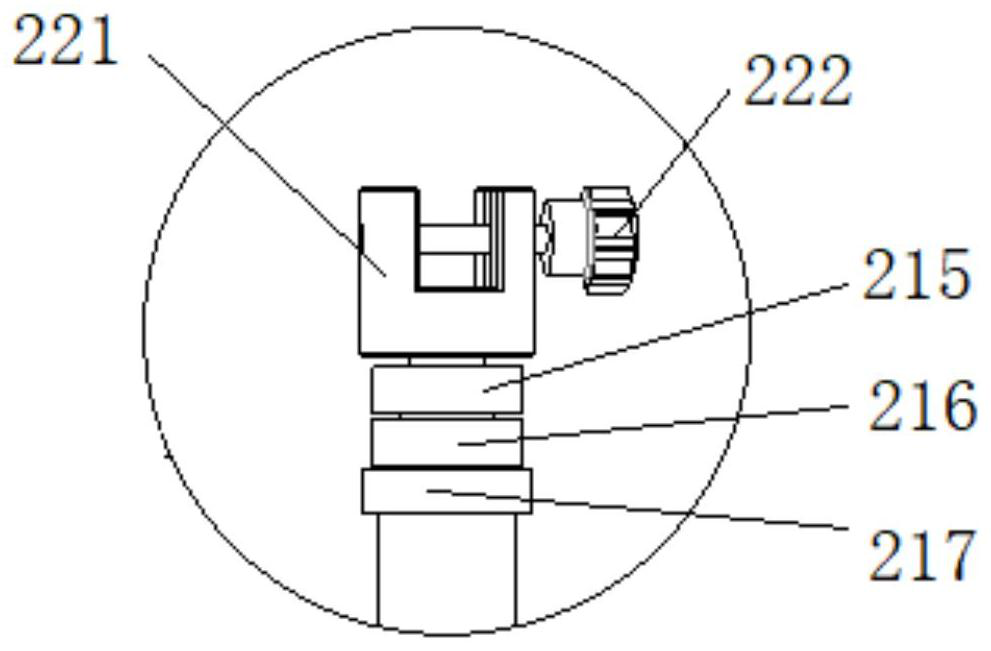

[0037] like Figure 1-Figure 4 As shown, the present invention provides a wire support frame, including a placement frame 1, a lift shaft 2, a chassis 3 and a support mechanism 4, the placement frame 1 is used to support the wire; the length of the lift shaft 2 is adjustable, and the placement frame 1 can be Detachably installed on one end of the lifting shaft 2; the bottom frame 3 is rotatably connected to the other end of the lifting shaft 2; the supporting mechanism 4 is slidably installed on the lifting shaft 2 and connected with the bottom frame 3, and the supporting mechanism 4 slides relative to the lifting shaft 2 , can drive the bottom frame 3 to expand or close. When the bottom frame 3 is unfolded, it is perpendicular to the lifting shaft 2 and can support the lifting shaft 2. When the bottom frame 3 is closed, it is attached to the lifting shaft 2.

[0038] In this embodiment, when using the wire support frame, the placement frame 1 is first installed on the lifting...

Embodiment 2

[0052] This embodiment provides a wire support frame, which is further improved on the basis of Embodiment 1 to further enhance the stability of the wire support frame.

[0053] More specifically, an anti-slip member is provided on the side of the pole 31 away from the supporting mechanism 4 . In this embodiment, the anti-slip member may be rubber to enhance the friction between the pole 31 and the ground.

[0054] More specifically, the bottom of the connection base 23 is provided with spikes, which can be inserted into the ground, so that the wire support frame is not easy to fall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com