A kind of equipment for painting both sides of industrial boards

An industrial and painting technology, which is applied to the device and coating of the surface coating liquid, which can solve the problems of time-consuming and labor-intensive painting, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] An industrial board two-sided painting equipment, such as figure 1 As shown, it includes a base 1, a pillar 2, a propulsion mechanism 3 and a painting mechanism 4. The front side of the base 1 is evenly provided with a pillar 2, and the rear side of the base 1 is provided with a propulsion mechanism 3. There is a painting mechanism4.

[0061] When it is necessary to paint the industrial board, the industrial board is first placed on the parts of the painting mechanism 4, then the propulsion mechanism 3 is controlled to drive the parts of the painting mechanism 4 to paint the industrial board, and the industrial board is taken out after completion. board.

Embodiment 2

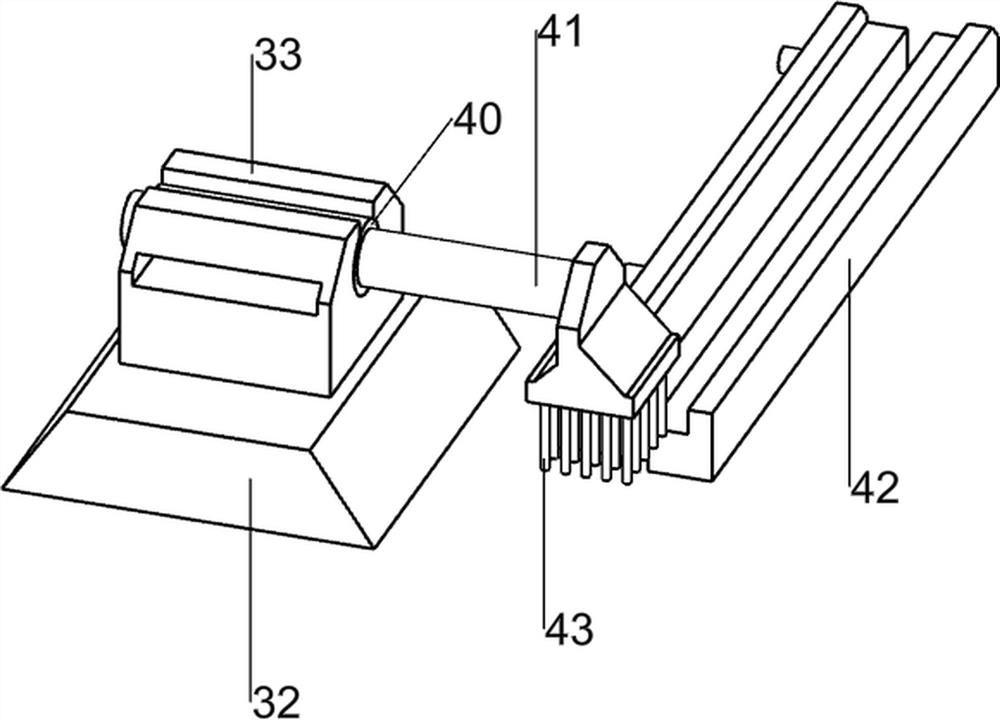

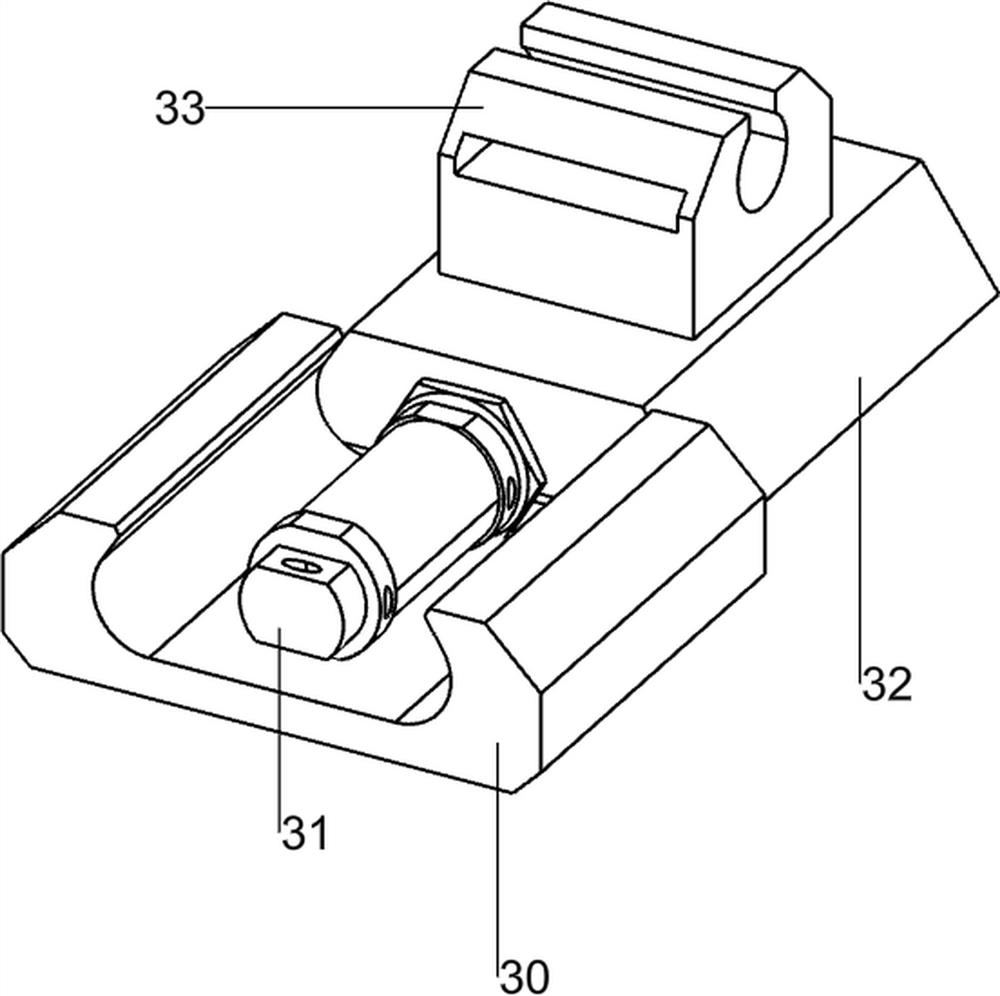

[0063] On the basis of Example 1, such as Figure 2-3 As shown, the propulsion mechanism 3 includes a mounting base 30, a cylinder 31, a sliding block 32 and a mounting block 33. The rear side of the base 1 is provided with a mounting base 30, and the left side of the mounting base 30 is provided with a cylinder 31. The mounting base 30 is slidingly connected. A sliding block 32 is arranged, and the sliding block 32 is connected with the cylinder 31. The top of the sliding block 32 is provided with a mounting block 33, and the mounting block 33 is connected with the painting mechanism 4.

[0064] After the industrial board is placed, the extension of the control cylinder 31 drives the sliding block 32 and the installation block 33 to move to the right, drives the parts of the painting mechanism 4 to paint the industrial board, and then controls the shortening of the cylinder 31 to drive the sliding block 32 and the installation block 33 Move left to reset.

[0065] The painti...

Embodiment 3

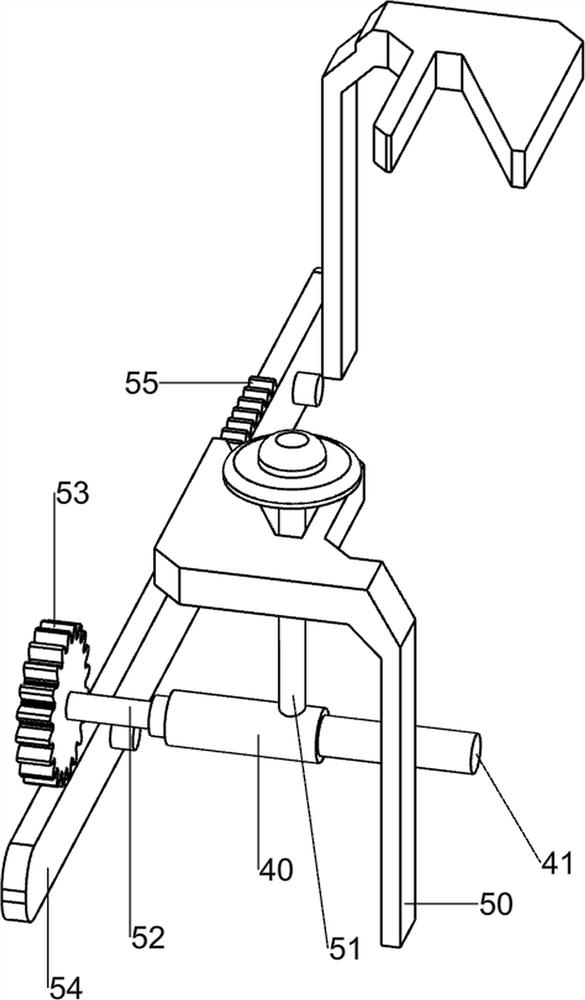

[0068] On the basis of Example 2, such as Figure 4-7As shown, it also includes a turning mechanism 5, and the turning mechanism 5 includes a mounting plate 50, a sliding column 51, a second rotating shaft 52, a first gear 53, a fixed plate 54 and a first rack 55, and the left front side and the right side of the mounting seat 30 The rear side is provided with a mounting plate 50, the hollow cylinder 40 top front side is provided with a sliding column 51, the first rotating shaft 41 rear side is provided with a second rotating shaft 52, the second rotating shaft 52 rear side is provided with a first gear 53, and the mounting seat 30 The rear side is provided with a fixed plate 54 , and the top right side of the fixed plate 54 is provided with a first rack 55 , and the first rack 55 meshes with the first gear 53 .

[0069] The hollow cylinder 40 moves to the right to drive the sliding column 51, the second rotating shaft 52, the first gear 53 and the first rotating shaft 41 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com