Crystallizer for continuous casting

A crystallizer and copper tube technology, applied in the field of continuous casting crystallizers, can solve the problems of high inner wall temperature of copper tubes, poor copper tube deformation resistance, low heat transfer coefficient, etc., to ensure heat transfer efficiency, enhance rigidity, The effect of enhancing the ability to resist thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present utility model is described below through specific examples, and those skilled in the art can easily understand other advantages and effects of the present utility model from the content disclosed in this specification. The utility model can also be implemented or applied through other different specific implementation modes, and the details in this specification can also be modified or changed based on different viewpoints and applications without departing from the spirit of the utility model. It should be noted that the illustrations provided in the following embodiments are only schematically illustrating the basic idea of the present utility model, and the following embodiments and the features in the embodiments can be combined with each other in the case of no conflict.

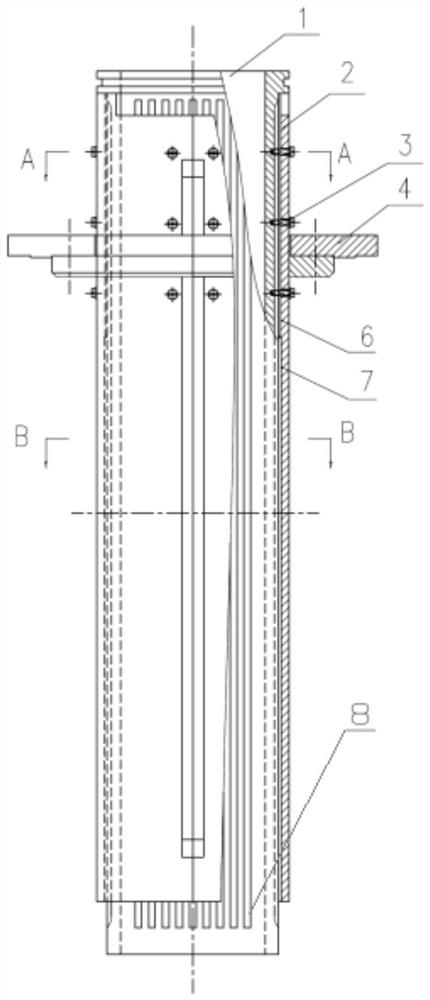

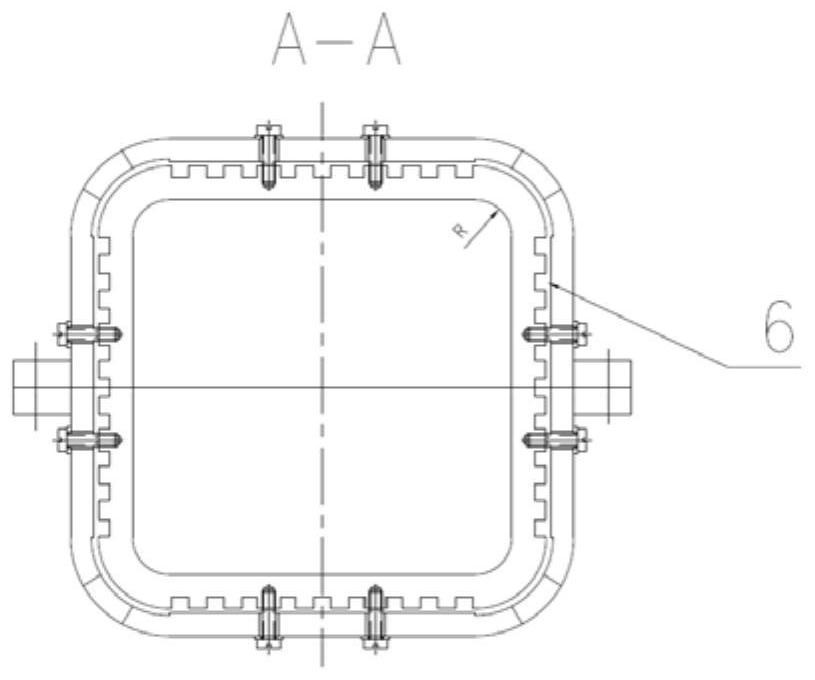

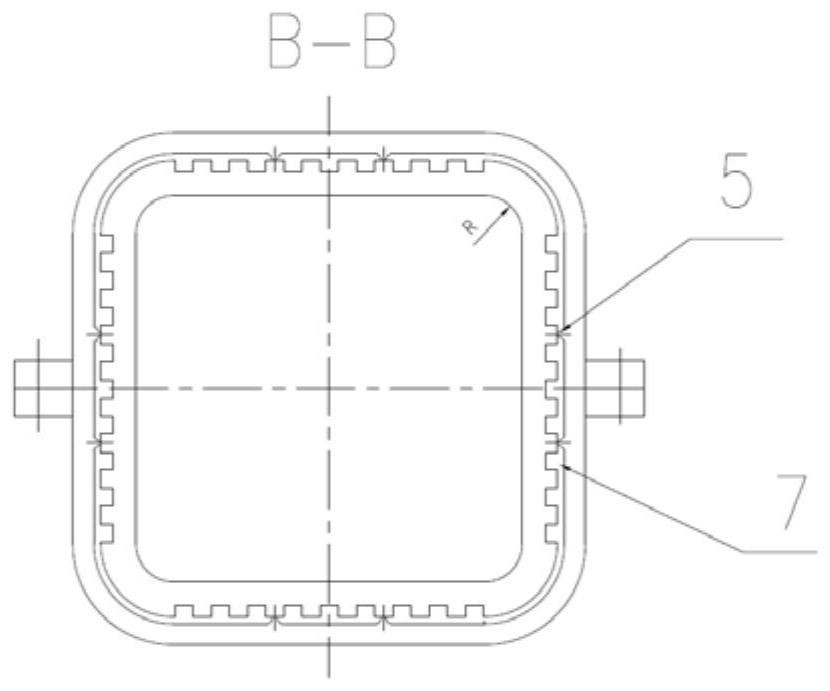

[0029] Such as Figure 1-4 As shown, in the crystallizer for continuous casting mentioned in this embodiment, the copper pipe 1 and the water jacket 2, the wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com