File structure with good balance effect and pressing function

A filing and balancing technology, which is used in manufacturing tools, filing/filing devices, filing/filing devices, etc., can solve problems such as time-consuming and labor-intensive, and achieve the effect of reducing operation difficulty, good balancing effect, and improving work accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

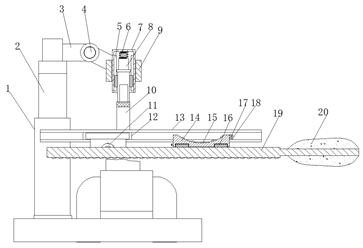

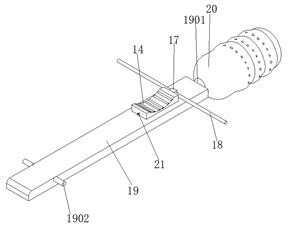

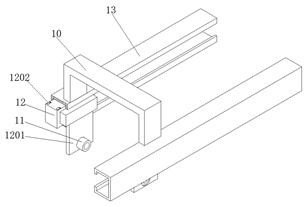

[0028] refer to Figure 1-4 , a file structure with a good balance effect and a press-down function, including a file body 19 and a support frame 1 fixed on a hydraulic clamp fixing platform, an extension rod 2 is arranged on the top of the support frame 1, and the top of the extension rod 2 The arm bar 3 is fixed, the end of the arm bar 3 is provided with a fixed frame 9, the middle of the fixed frame 9 is clamped with a fixed bucket 7 with the opening downward, and the bottom opening of the fixed bucket 7 is slidably connected with an electric push rod 8 The upper and lower ends of the electric push rod 8 are respectively fixed with a compression spring 6 and a bow frame 10, and the bottom end of the bow frame 10 is fixed with two C-shaped steel slide rails 13 with opposite openings and parallel to each other, and the two C-shaped steel slide rails 13 T-shaped sliders 12 are slidably connected in the chute, bearing fixing plates 1201 are fixed on opposite sides of the two T-...

Embodiment 2

[0038] refer to figure 1 and Figure 5 , a file structure with a good balance effect and a pressing function. Compared with Embodiment 1, this embodiment also includes that the span of the bow frame 10 is greater than the distance between two C-shaped steel slide rails 13, and the bow frame 10 Both legs are provided with threaded holes close to the back of the C-shaped steel slide rail 13 and the back of the C-shaped steel slide rail 13. Adjusting bolts 22 are screwed in the threaded holes, and the two C-shaped steel slide rails 13 of the bow frame 10 are fixed by the adjusting bolts 22. together, and the inclination angle of the C-shaped steel slide rail 13 can be changed according to the angle of the workpiece's foiling plane, so that the user can foil an inclined plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com