Inkjet printer

An inkjet printer and print head technology, applied in printing and other directions, can solve problems such as ineffectiveness and inability to use regulators, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, an inkjet printer according to an embodiment of the present invention will be described with reference to the drawings.

[0050]

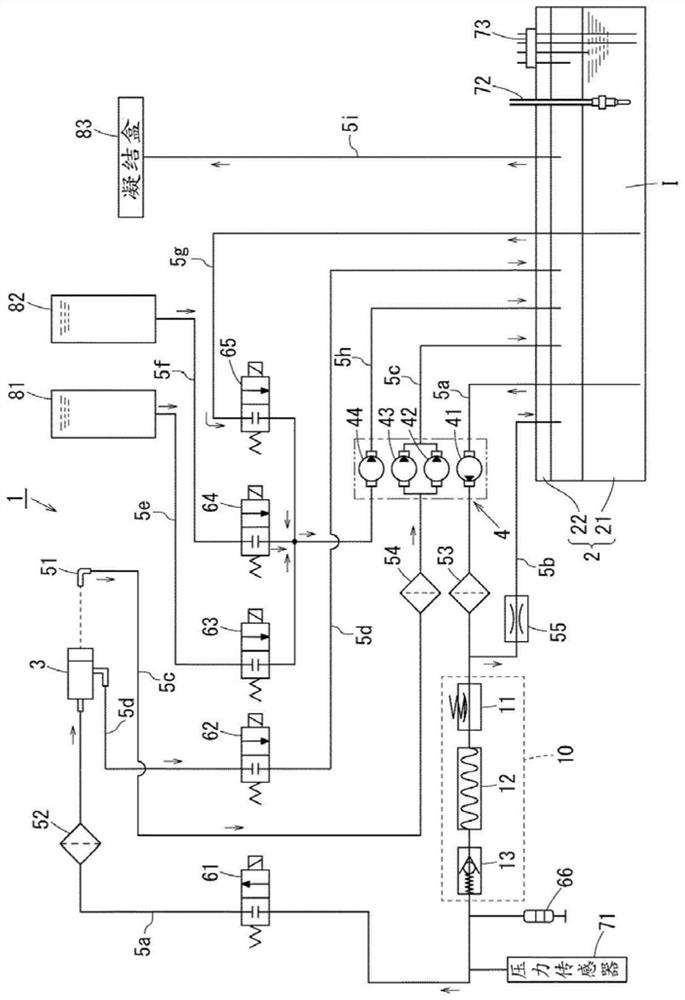

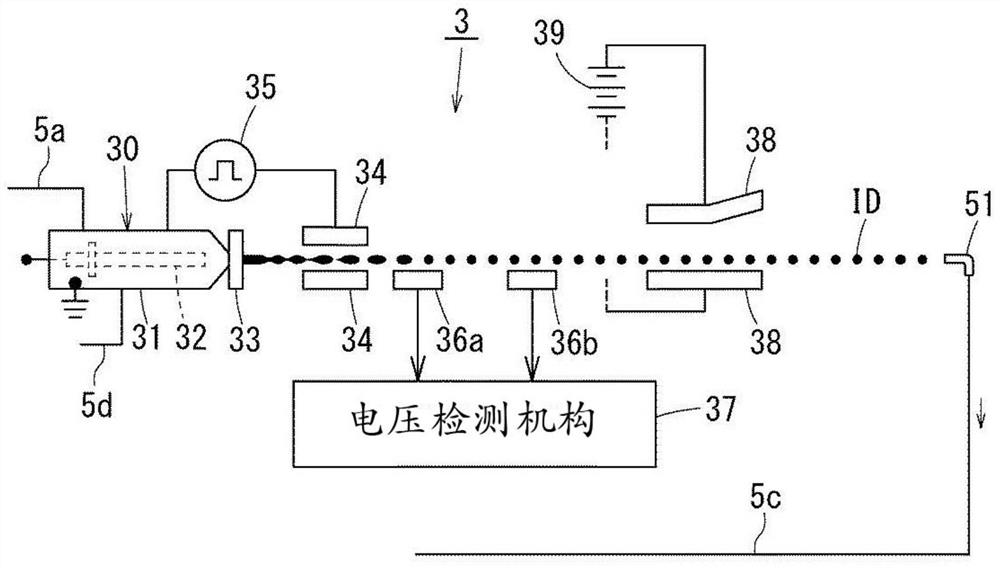

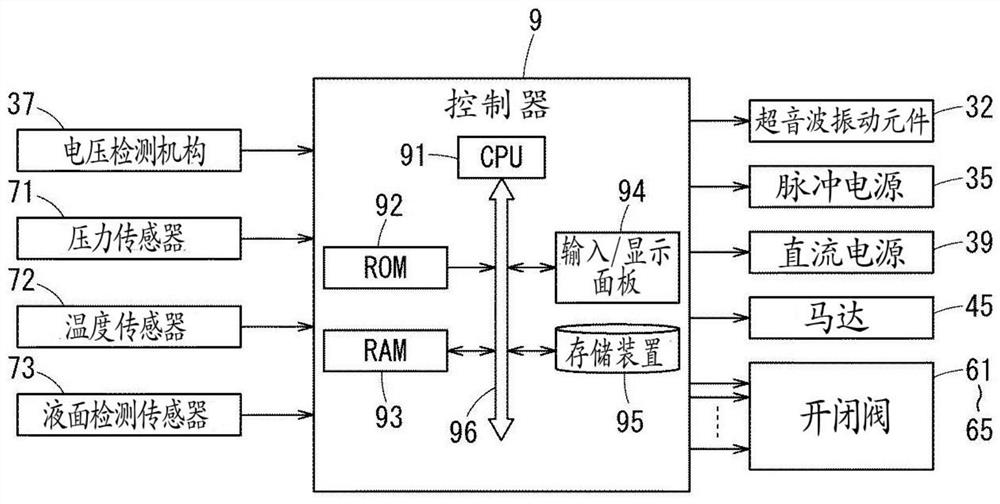

[0051] figure 1 It is a piping diagram showing the inkjet printer according to the embodiment of the present invention, figure 2 yes means figure 1 Schematic diagram of the print head of the printer. in addition, image 3 yes means figure 1 The block diagram of the control system of the printer.

[0052] First, refer to figure 1 , to describe the configuration of the printer other than the print head, and then, refer to figure 2 , to explain the composition of the print head, and finally refer to image 3 , the configuration of the controller 1 will be described.

[0053] Such as figure 1 As shown in the piping diagram of , an inkjet printer (hereinafter referred to as "printer") 1 is composed of the following parts, namely: an ink cartridge 2 for storing ink 1, a print head 3 for ejecting ink to print on the surfac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap