Tooling and method for connecting rigid heat protection layer to non-enclosed equal-diameter revolving cabin section

A heat protection layer and non-enclosed technology, applied in the direction of connecting components, material gluing, weight reduction, etc., can solve the problems of high profile requirements, low efficiency, and complicated assembly process of the aircraft, so as to avoid interference and damage the cabin, and can be operated Strong and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

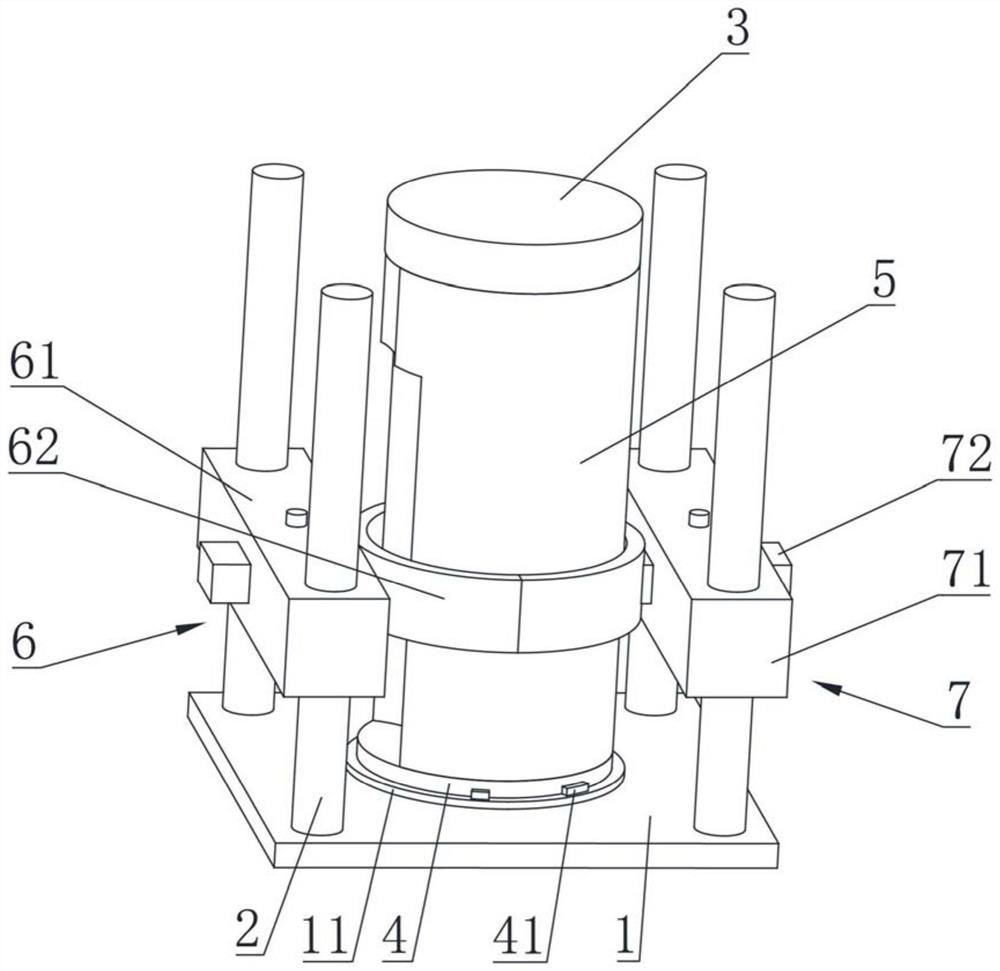

Embodiment 1

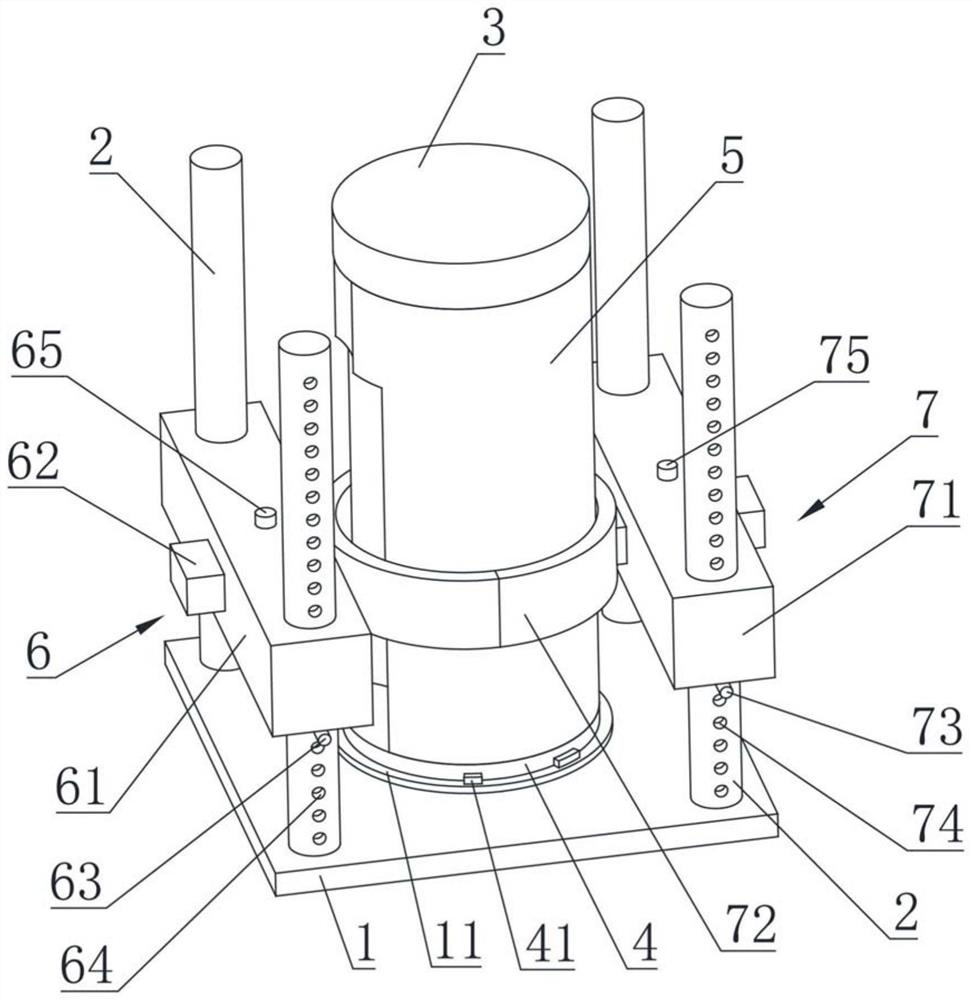

[0066] In this embodiment, between the first axial sliding portion 61 and the column 2, and between the first radial sliding portion 62 and the first shaft

[0068] The structures of the first radial sliding portion 62 and the second radial sliding portion 72 include a connecting portion and a solid portion.

[0074] It should be noted that, the two side molds of the sliding mold, each side mold can also be installed on other numbers of uprights 2,

Embodiment 2

[0077] A plurality of second adjustment holes 74 are provided on at least one column 2 for installing the second axial sliding portion 71,

[0078] Preferably, the first axial sliding portion 61 is also provided with a first radial adjustment perpendicular to the first installation hole

[0079] The second axial sliding portion 71 is also provided with a second radial adjustment screw hole perpendicular to the second mounting hole, so

Embodiment 3

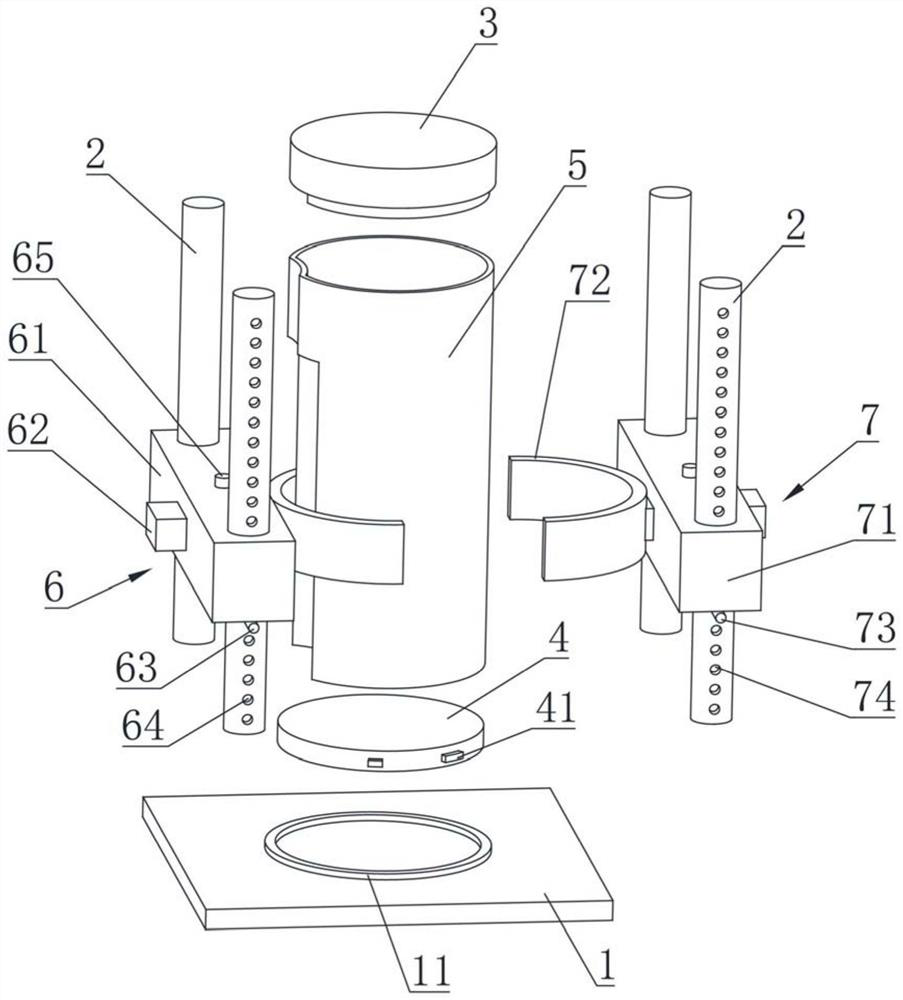

[0082] Referring to FIG. 4, a tooling structure is shown, including two sliding dies, of course in other embodiments

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com