Cotton filling machine for stuffed toy processing

A plush toy, cotton filling machine technology, applied in toys, dolls, entertainment and other directions, can solve the problems of plush toys impact force, difficult to adjust the height of the cotton filling machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

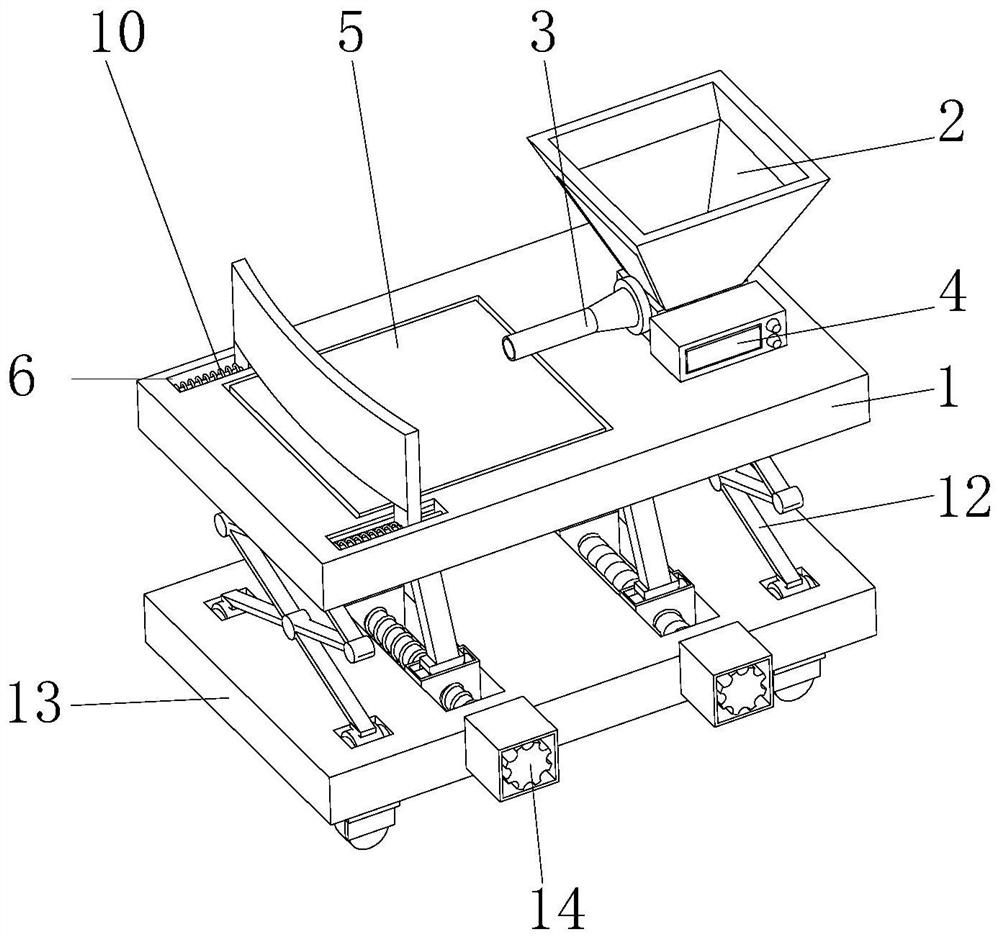

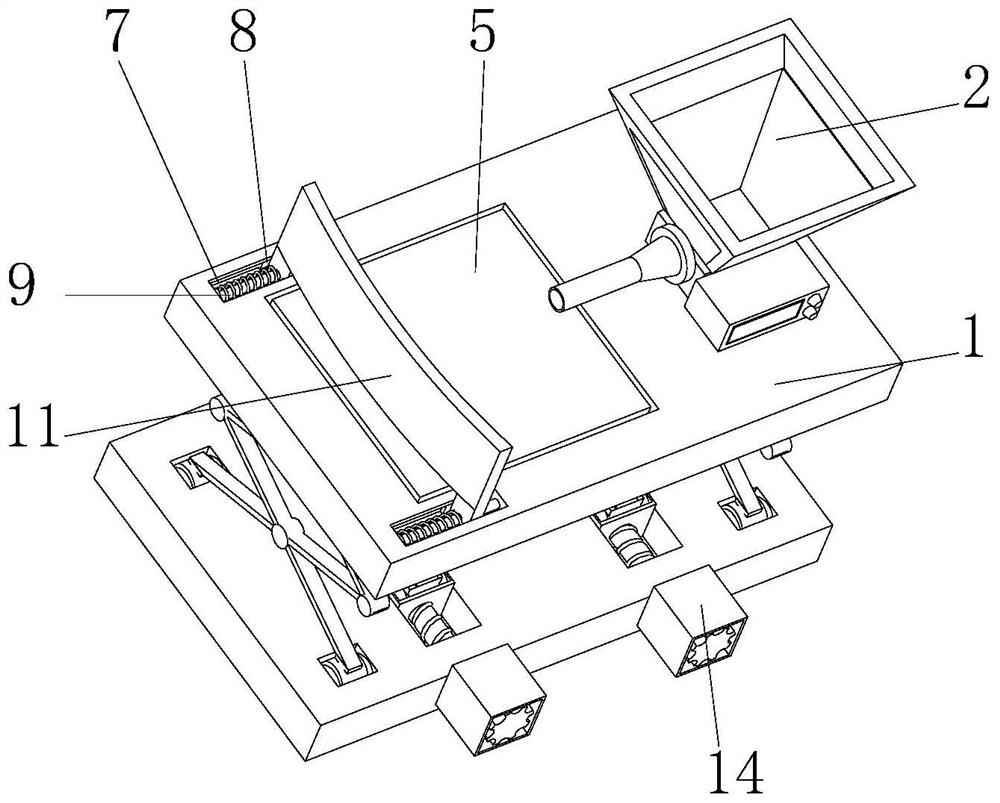

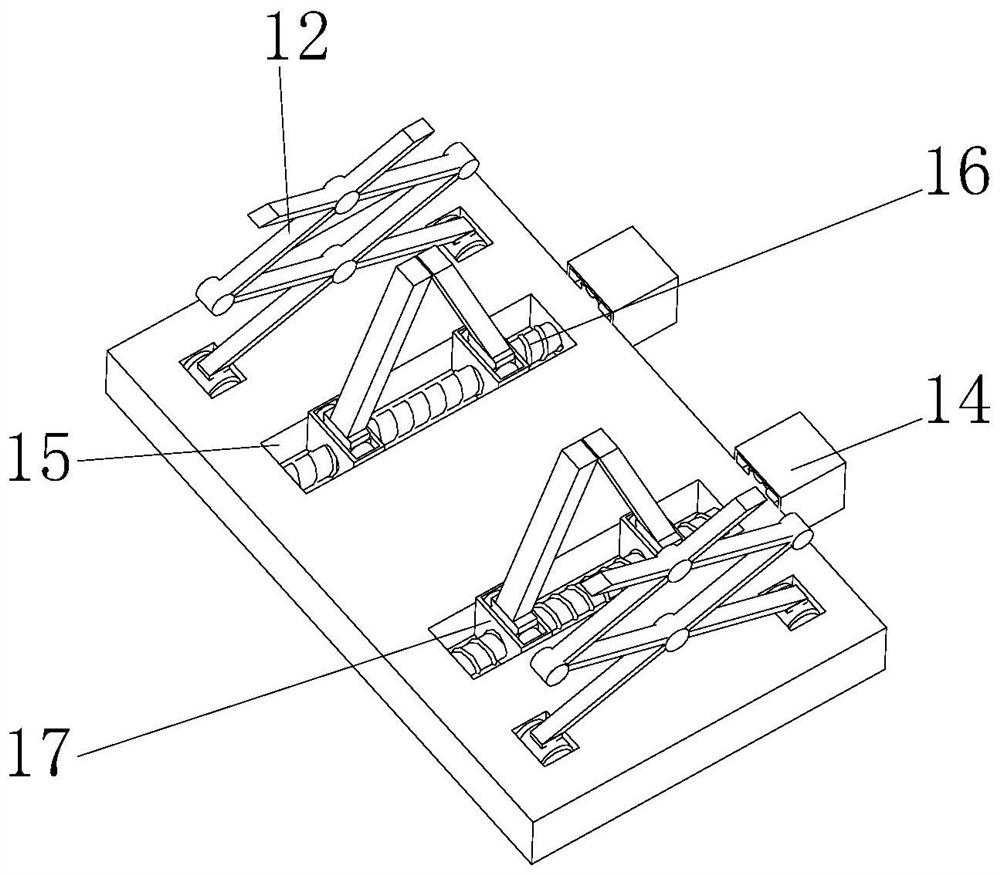

[0027] see Figure 1-4 , the present invention provides the following technical solutions: a cotton filling machine for plush toy processing, including a bearing platform 1, a conical cotton storage bin 2 is fixedly connected to the bearing platform 1, and the side of the conical cotton storage bin 2 is fixedly connected with The cotton blowing pipe 3 is provided with a first groove 6 on the carrying platform 1, and a sliding rod 9 is fixedly connected in the first groove 6, and a first spring 10 is set on the sliding rod 9, and the sliding rod 9 slides A baffle 11 is connected, the two ends of the first spring 10 are respectively fixedly connected with the slide bar 9 and the baffle 11, the bottom of the carrying platform 1 is connected with a telescopic frame 12 through a rotating shaft, and the bottom of the telescopic frame 12 is connected with a base through a rotating shaft 13. The motor 14 is fixedly connected to the side of the base 13. The base 13 is provided with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com