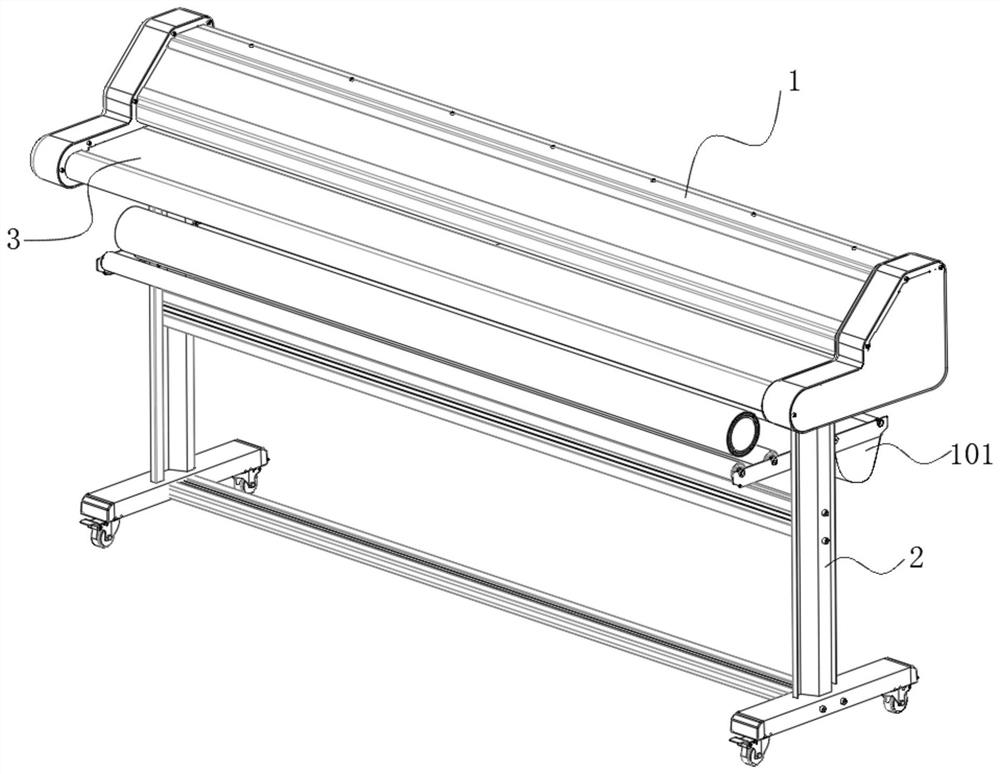

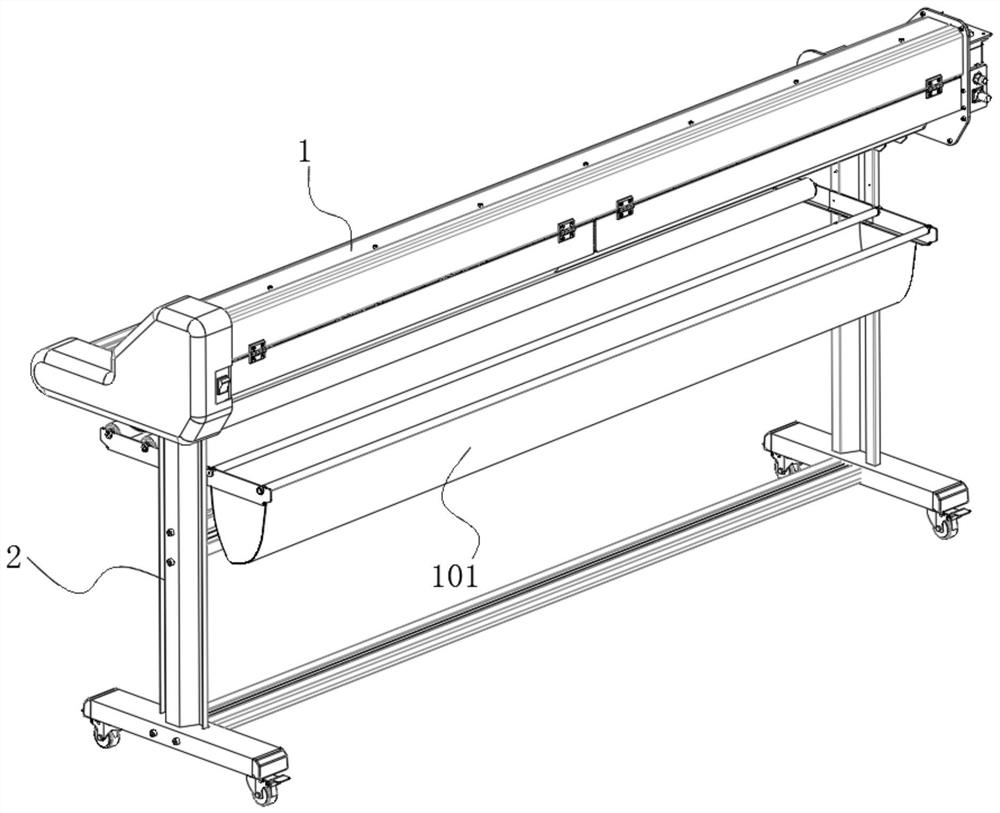

Cutter mechanism for cutting sheet-shaped material

A sheet material and cutting knife technology, applied in the field of cutting machines, can solve the problems of cutting edge wear and affect cutting effect, etc., to achieve smooth cutting surface, improve grinding effect, and increase cutting rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

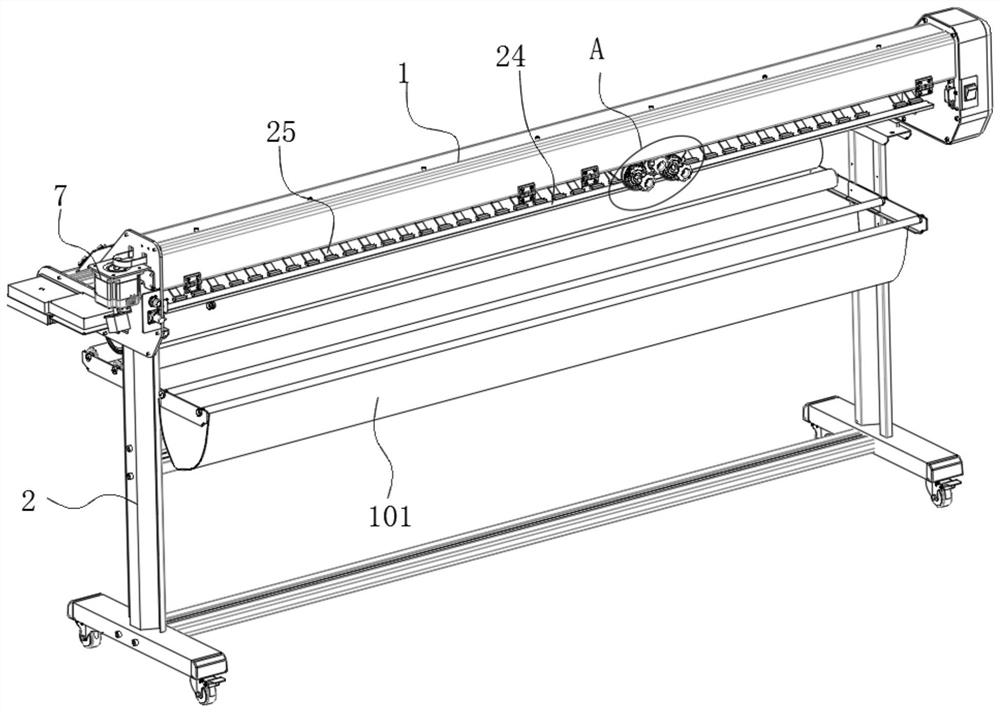

[0045] To make the purpose, technical solutions and advantages of the embodiments of the present disclosure clearer, the technical solutions of the embodiments of the present disclosure will be clearly and completely described below in conjunction with the drawings of the embodiments of the present disclosure.

[0046] see Figure 1-19, a cutter mechanism for cutting sheet materials provided by the present invention, by setting two disc cutters 4 at a certain angle with the grinding surface 2401 on the bearing seat 24, and the disc cutters 4 The edge of the cutting surface is in contact with the grinding surface 2401 on the carrier 24 to form a shearing mode of staggered blade shearing, so that when cutting, the degree of wear on the blade surface of the disc cutter 4 can be greatly reduced, and the The cutting edge of the disc cutter 4 has a certain self-grinding effect, and can greatly improve the cut-off rate of the cutout. On the first central axis 11, the two disc cutter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com