A quartz powder grinding device

A grinding device and technology of quartz powder, which is applied in the field of grinding, can solve problems such as insufficient grinding of quartz powder and inability to adjust the fineness of grinding, and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

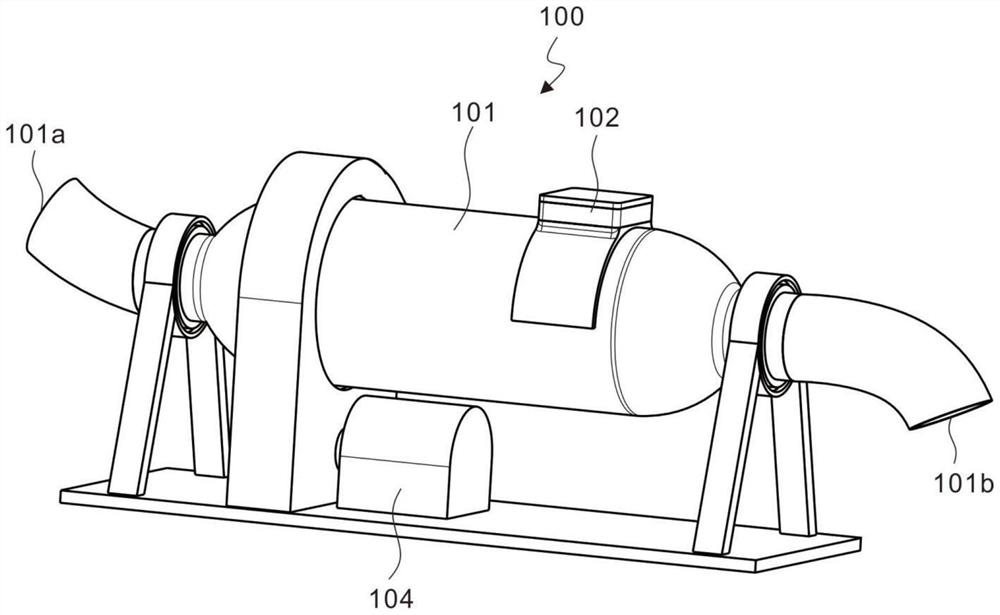

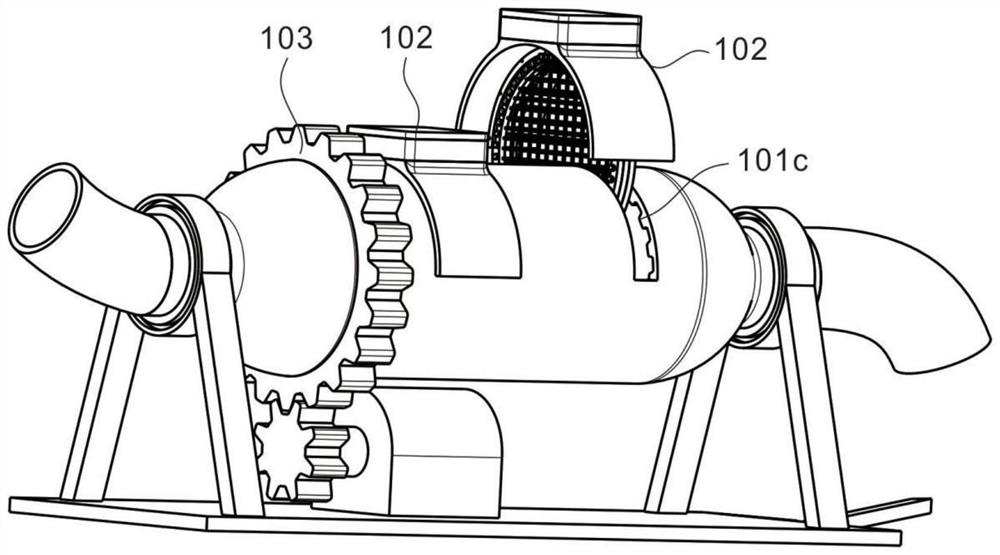

[0033] refer to figure 1 , image 3 with Figure 8 , is the first embodiment of the present invention, and this embodiment provides a kind of quartz powder grinding device, and quartz powder grinding device comprises grinding unit 100, and quartz powder and deionized water enter from feed port 101a, grind, when grinding fully Afterwards, it flows out from the discharge port 101a through the filter screen gap of the layered assembly 102.

[0034] It should be noted that steel balls of various specifications are arranged in the drum 101, and the drum 101 is driven to rotate by the first driving member 104, and the quartz powder is ground by the steel balls.

[0035] Specifically, the grinding unit 100 includes a drum 101, a layered component 102 that cooperates with the drum 101 and acts as a barrier, a first gear 103 that is arranged on the outer wall of the drum 101, and a gear that cooperates with the first gear 103 The first driving member 104 is a stepping motor, and its...

Embodiment 2

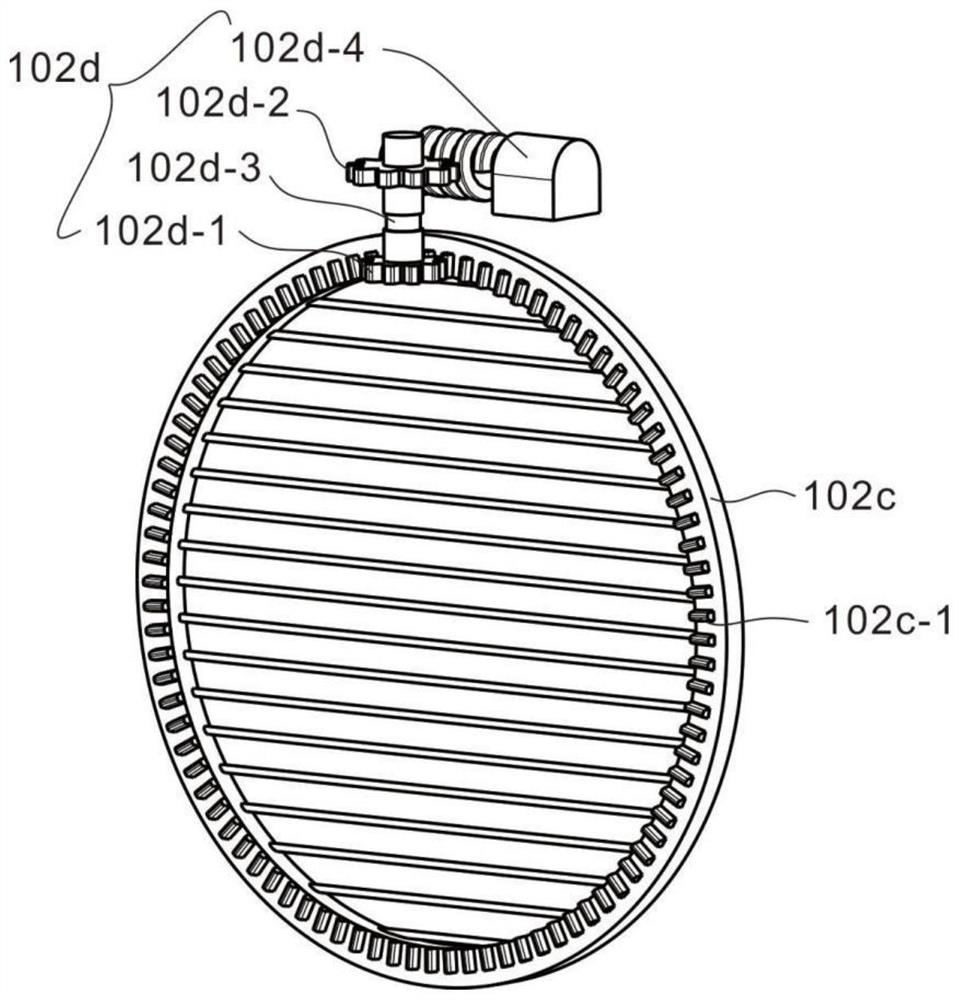

[0044] refer to figure 2 , Figure 4~7 , Figure 9 with Figure 10 , is the second embodiment of the present invention, which is different from the first embodiment in that: it also includes a discharge unit 200, and there are two second filter elements 102c. In the last embodiment, the quartz powder grinding device includes a grinding unit 100. Quartz powder and deionized water enter from the feed port 101a for grinding. flow out.

[0045] Steel balls of various specifications are arranged in the drum 101, and the drum 101 is driven to rotate by the first driving member 104, and the quartz powder is ground by the steel balls.

[0046] The grinding unit 100 includes a drum 101, a layered assembly 102 that cooperates with the drum 101 and acts as a barrier, a first gear 103 arranged on the outer wall of the drum 101, and a first drive that cooperates with the first gear 103 Item 104.

[0047] Both ends of the drum 101 are respectively provided with a material inlet 101a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com