A safety detection device for power distribution

A technology of safety detection and traveling mechanism, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of easy slipping of friction wheels, inconvenient determination of cable node positions, rise in wire temperature, etc., and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

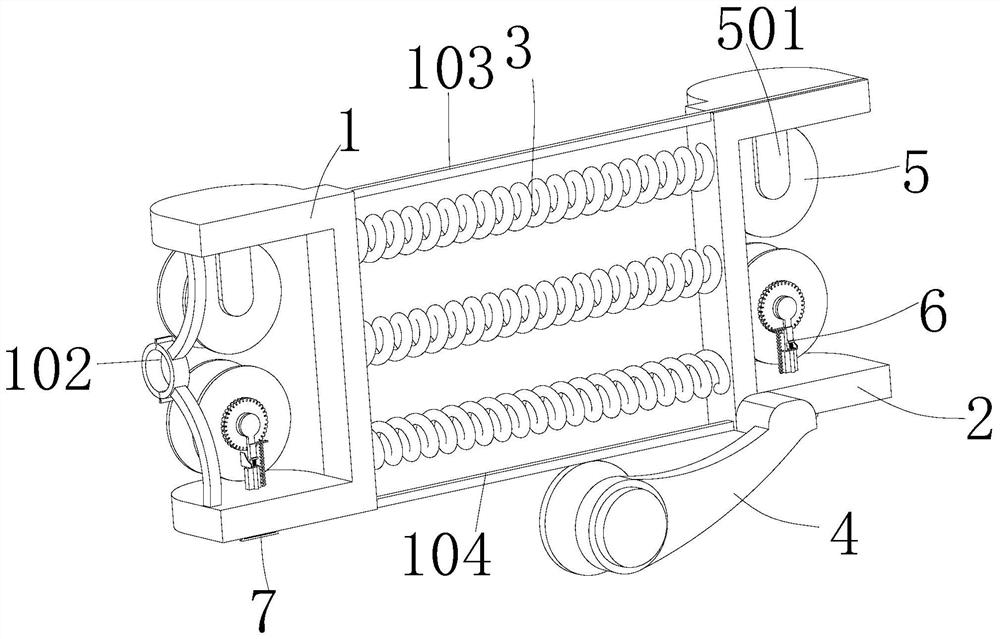

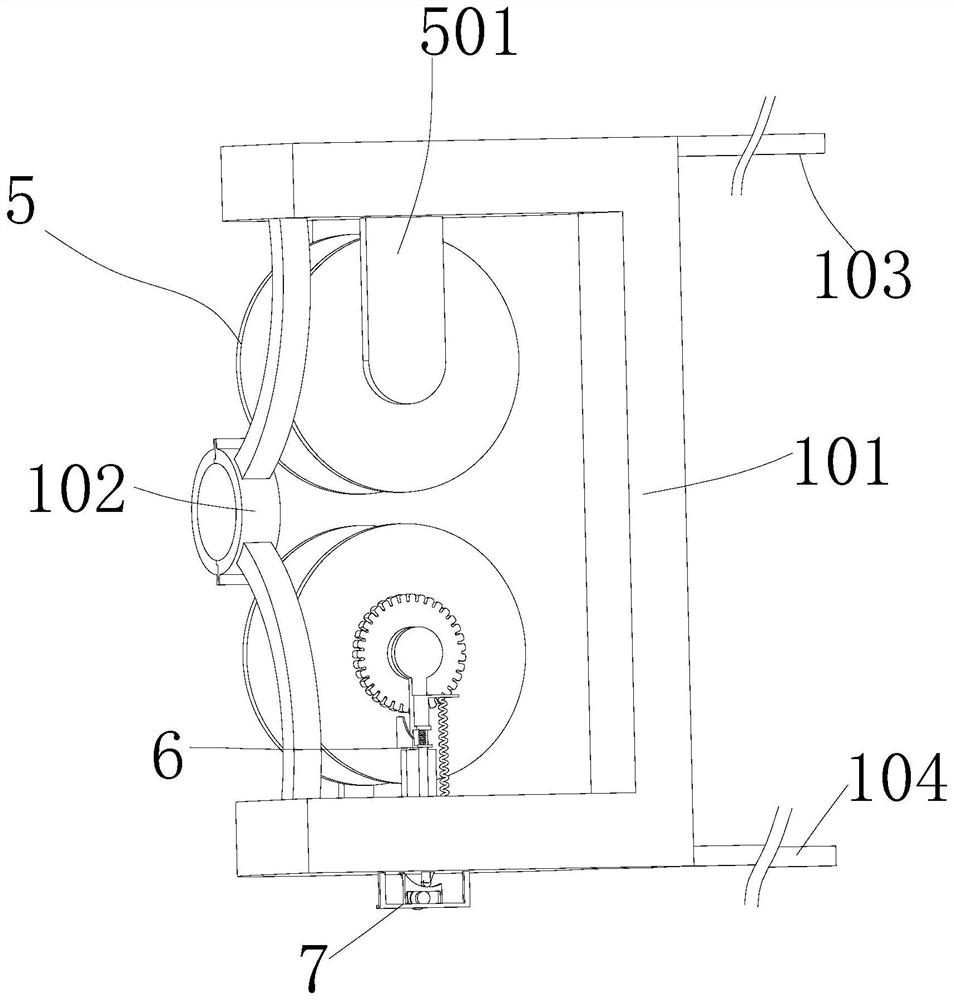

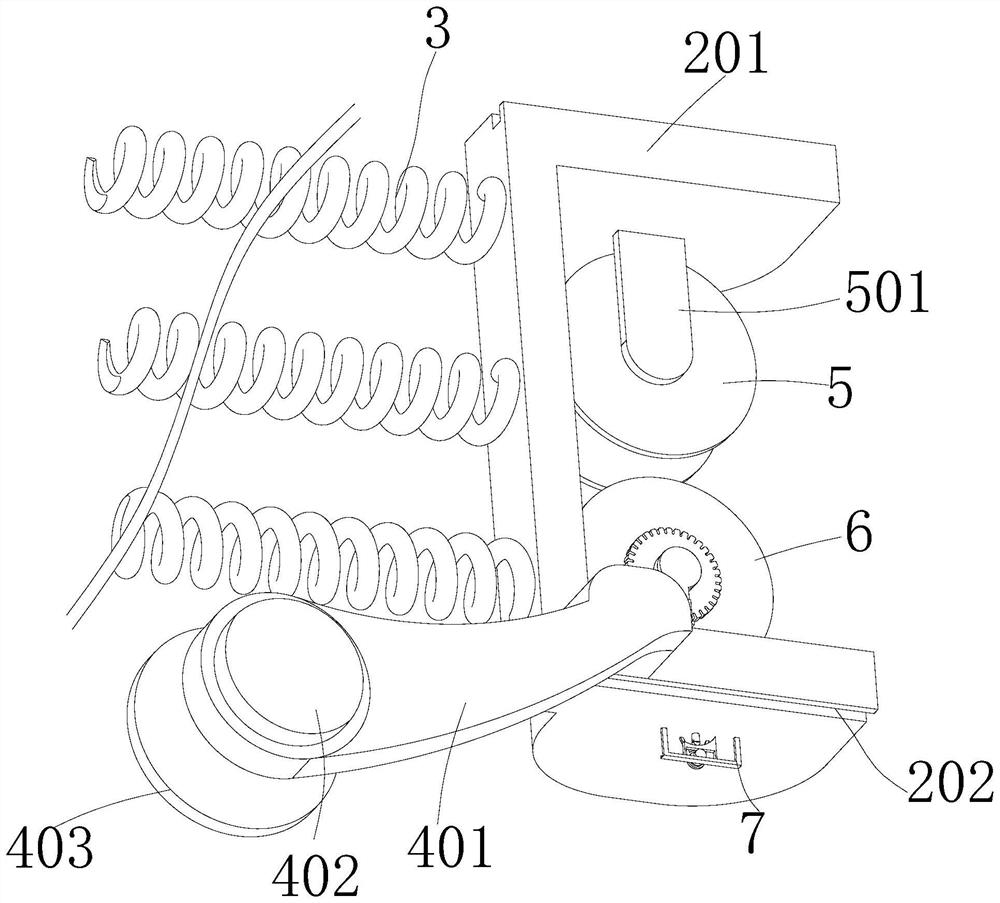

[0025] Example one, as Figure 1-7As shown, it includes a front running mechanism 1 and a rear running mechanism 2, the front running mechanism 1 and the rear running mechanism 2 are slidably connected, the front running mechanism 1 and the rear running mechanism 2 are alternately locked, and the front running mechanism 1 and the rear running mechanism 2 They are fixedly connected by a compression spring 3, a power mechanism 4 is fixedly installed on the front side of the lower end of the rear traveling mechanism 2, and the power mechanism 4 is engaged with the front traveling mechanism 1. The inner upper ends of the front traveling mechanism 1 and the rear traveling mechanism 2 are fixedly installed with a fixed Wheel 5, a pressing mechanism 6 is fixedly installed on the inner lower ends of the front traveling mechanism 1 and the rear traveling mechanism 2, and a pressing mechanism 7 is fixedly installed on the outer lower ends of the front traveling mechanism 1 and the rear t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com