Cable duct inspection robot

A technology for inspection robots and cable ducts, applied to cable laying equipment, etc., can solve problems such as inability to maintain and repair, impact on the surrounding environment, and excessive engineering waste, and achieve the effects of simple structure, weight reduction, and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described in detail below with reference to the accompanying drawings.

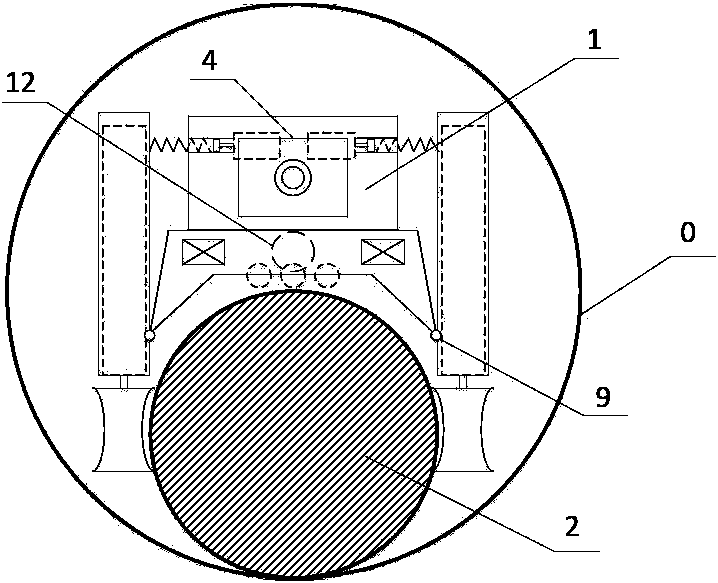

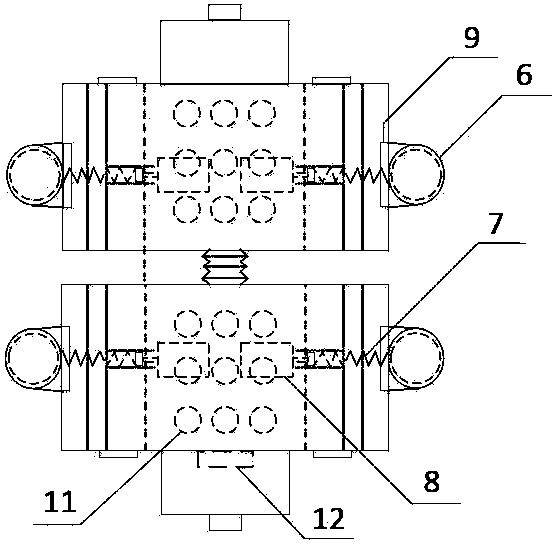

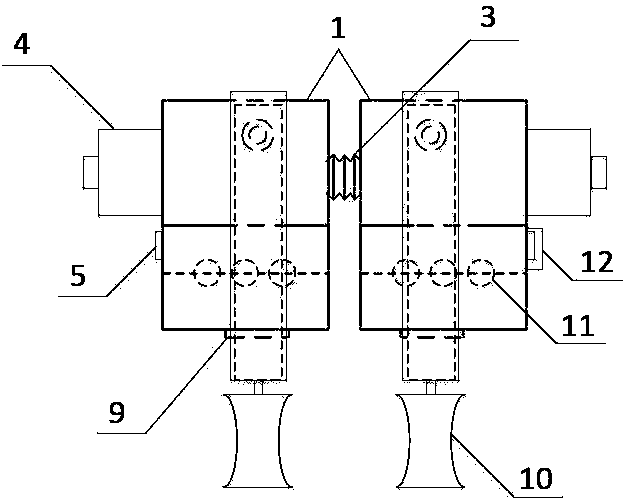

[0027] like figure 1 , 2 , 3, the present invention includes a two-segment vehicle body 1, a camera detection assembly arranged in the front and rear of the vehicle body 1, a walking mechanism and its auxiliary moving mechanism arranged on both sides of the vehicle body 1; the camera detection assembly includes Two high-definition cameras 4 and two sets of variable-brightness LED lights 5. The traveling mechanism includes two sets of traveling wheels 10 and a motor that drives the traveling wheels 10 to roll. The rotating shafts of the traveling wheels 10 connected to the motors are arranged vertically. The side of the cross-section is concave arc to clamp the cable 2 laid in the pipeline 0 to move. 10. The pushing mechanism for clamping the cable 2; the vehicle body 1 is provided with a controller, and the controller is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com