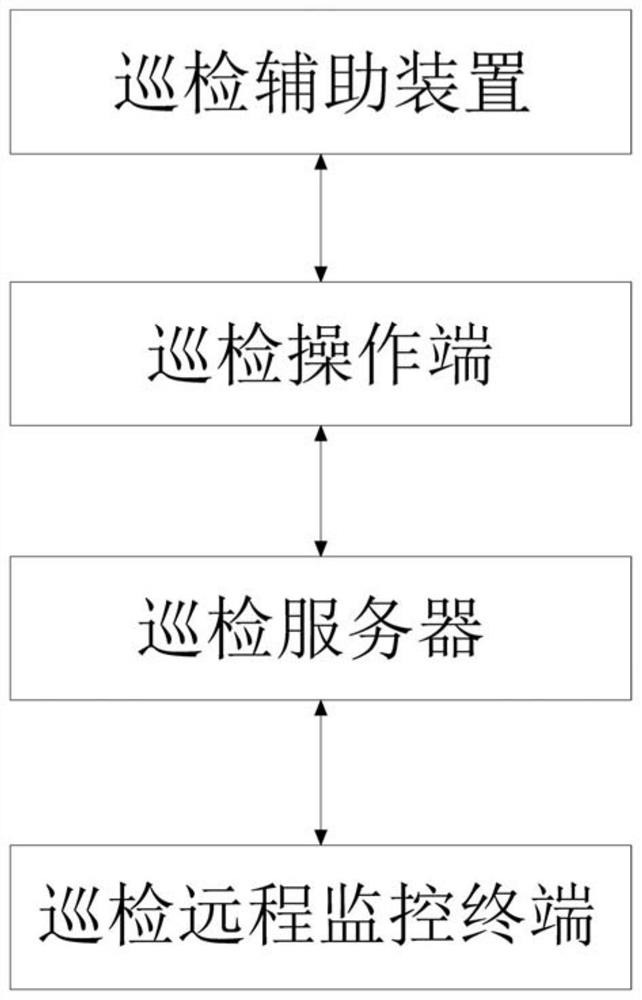

Patrol and point inspection auxiliary system

An auxiliary system and spot inspection technology, applied in two-way work systems, closed-circuit television systems, TV system components, etc., can solve problems such as inadequate inspections, incomplete inspections, and incorrect recorded information, so as to avoid occurrence probability, Ensure the effect of inspection in place and great supervision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

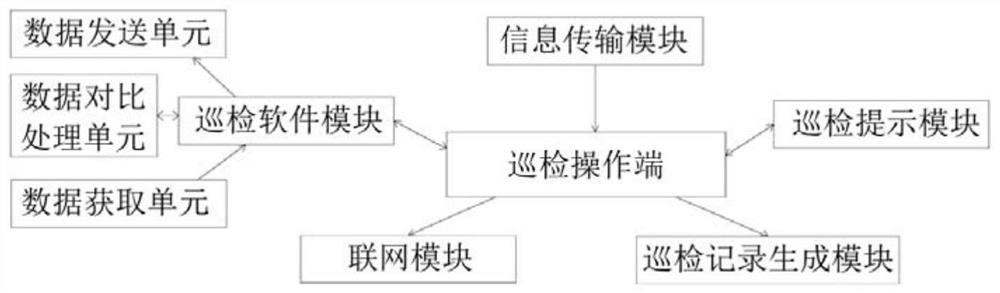

[0038] The inspection personnel first wear the inspection auxiliary device, and connect the interface unit of the inspection auxiliary device with the smartphone and PC at the inspection operation terminal through the USB interface and data cable, and connect the inspection inspection auxiliary system to the inspection operation terminal. Access to the Internet, the inspection personnel operate the inspection operation terminal, start the inspection software module to select the inspection line, and perform on-site inspection of the equipment according to the prompts of the inspection auxiliary system. During the inspection process, input the equipment parameters and working conditions according to the system inspection voice, and communicate with Compare the historical data, fill in the exception information and confirm the report.

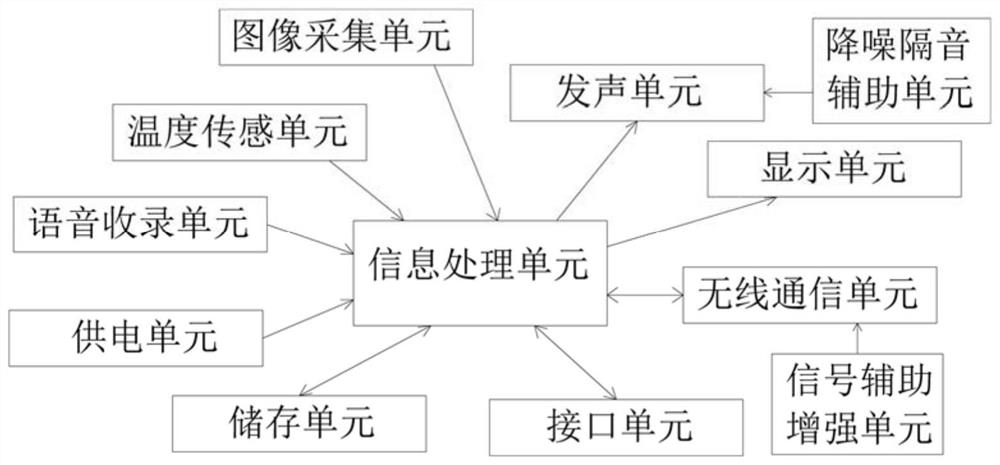

[0039] After wearing the inspection auxiliary device and starting to select the required inspection line, the power supply unit first supplies po...

Embodiment 2

[0048] This embodiment is similar to Embodiment 1, the difference is that the sound generating unit in this embodiment is equipped with a noise-reducing and sound-insulating auxiliary unit. Since the machine will generate relatively large noise during operation at the equipment site of the unit, by reducing The noise insulation auxiliary unit can reduce the impact of noise on the inspection site on sound reception, so that inspection personnel can clearly and accurately obtain inspection operation instructions.

[0049] And in the wireless communication unit in this embodiment, the auxiliary signal enhancement unit is added online. Due to the large coverage of the power plant unit, the communication signal reception in some areas of the power plant is poor, and the auxiliary signal enhancement unit can effectively improve the inspection auxiliary device. The stability of signal sending and receiving ensures the normal and smooth transmission of information data when the inspect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com