Glass full-size warping evenness detection device and detection method

A detection device and flatness technology, applied in the field of optical detection, can solve problems affecting the performance of glass products, failure to achieve comprehensive detection, and products entering the market, so as to improve quality and performance, reduce the output of defective products, and save The effect of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

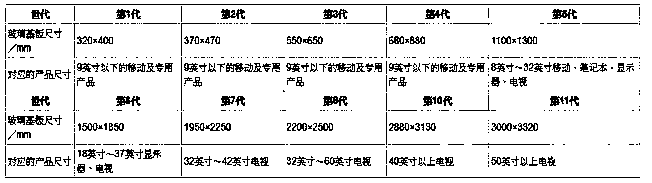

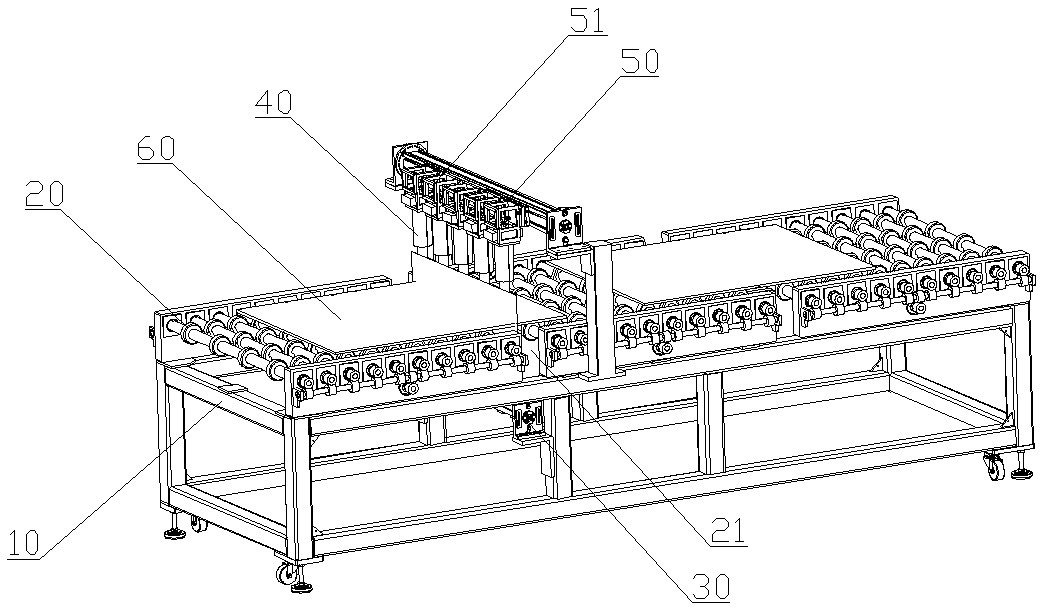

[0034] figure 2 It shows a structural schematic diagram of an embodiment of the glass full-scale warping flatness detection device of the present invention, and is also a schematic diagram of a preferred embodiment. like figure 2 As shown, the glass full-scale warping flatness detection device described in this embodiment includes: a frame 10, a conveying module 20, a lighting module 30, an imaging module 40, a camera module 50, and an image processing module ( not shown in the figure), wherein, the frame 10 is used to carry the module set on it; the transport module 20 is set above the frame 10, and is used to transport the sample 60 to be tested; the The illumination module 30 is arranged under the frame 10, and is used to provide illumination for warpage flatness detection, and the light emitted by the illumination module is incident on the sample to be tested in the transport module; the imaging module Group 40 is arranged above the frame, and the light emitted by the ...

Embodiment 2

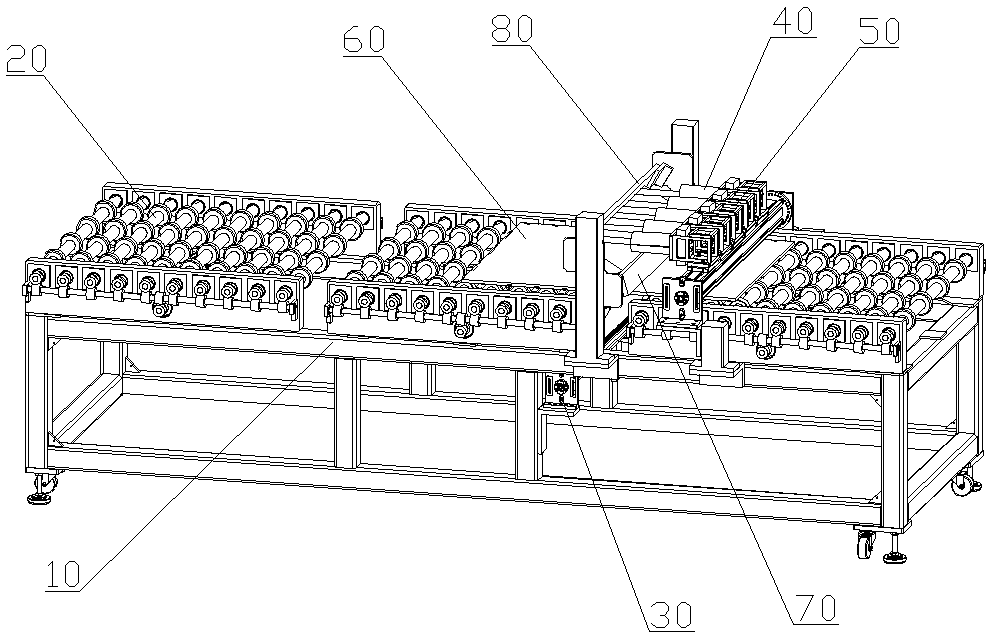

[0040] It is worth mentioning that this embodiment is optimized on the basis of the first embodiment, which can meet the detection requirements of higher standards. Therefore, the structure of each module described in the first embodiment is also applicable to the second embodiment. I won't repeat them here. Further, such as image 3 As shown, a reflector 70 is also provided above the frame 10 in this embodiment, and a uniform flat plate 80 is provided at the front end of the imaging module 40. The uniform flat plate 80 in this embodiment is preferably a white uniform flat plate. During detection, the light The light emitted by the module enters the reflector 70 after passing through the sample 60 to be tested, and is projected onto the uniform flat plate 80 after being reflected by the reflector 70. The image on the uniform flat plate is collected by the imaging element 50, and the collected image Send it to the image processing module to perform the calculation of the warpa...

Embodiment 3

[0043] This embodiment provides a method for detecting full-scale warping and flatness of glass, which includes the following steps:

[0044] Step A, place the sample to be tested at the front end of the conveying module, and the sample to be tested moves to the rear end of the conveying module under the drive of the conveying module; in this step, as described in Embodiment 2, the automatic feeding mechanism can be used to The sample to be tested is placed at the front end of the conveying module;

[0045] Step B. When the sample to be tested moves to the gap area of the conveying module, the linear light emitted by the linear light source in the illumination module enters the sample to be tested after passing through the standard grid;

[0046] Step C, the linear light transmitted by the sample to be tested enters the imaging module for imaging;

[0047] Step D, the line array camera in the camera module collects continuous segmented images of the sample to be tested, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com