hand tool machine

A technology of tools and machines, applied in the field of hand-held tools and machines, can solve problems such as difficult manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

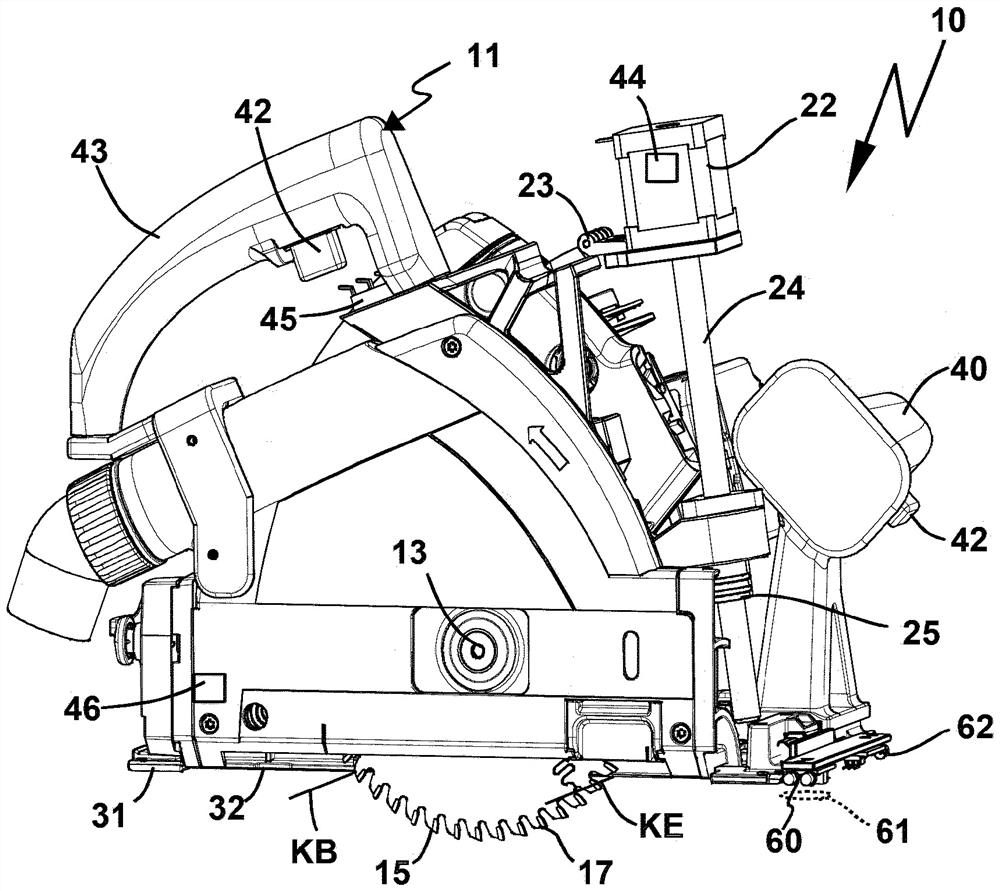

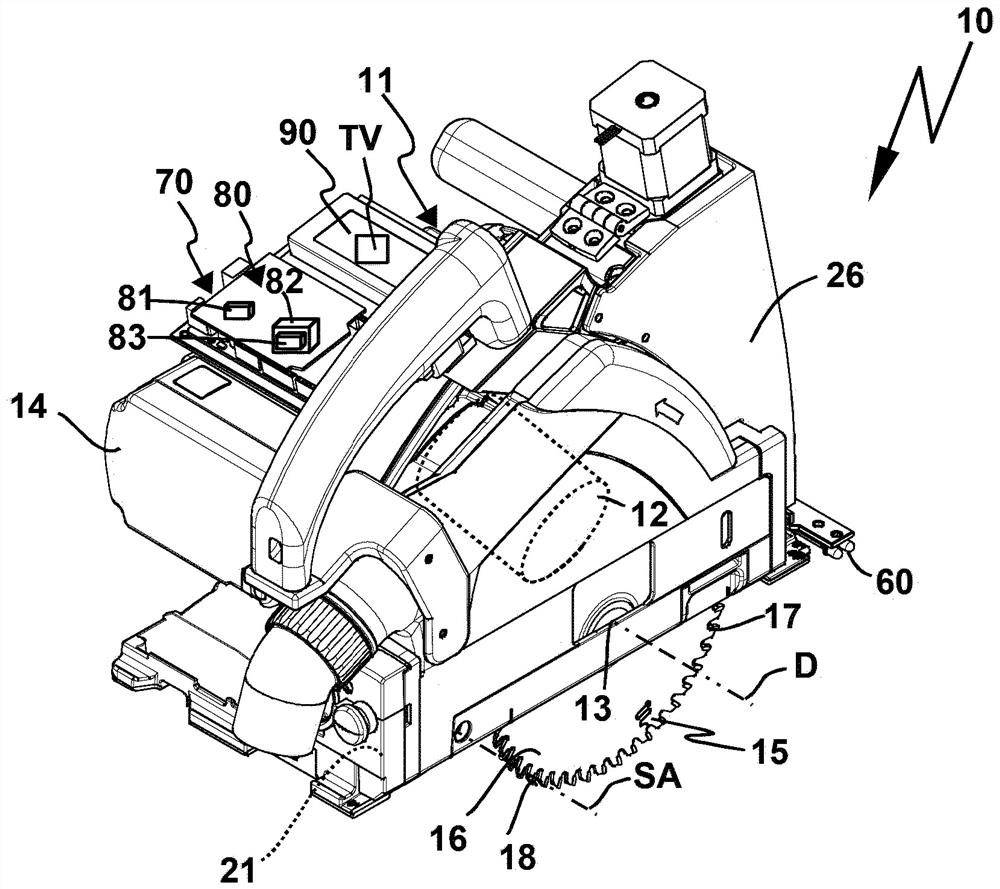

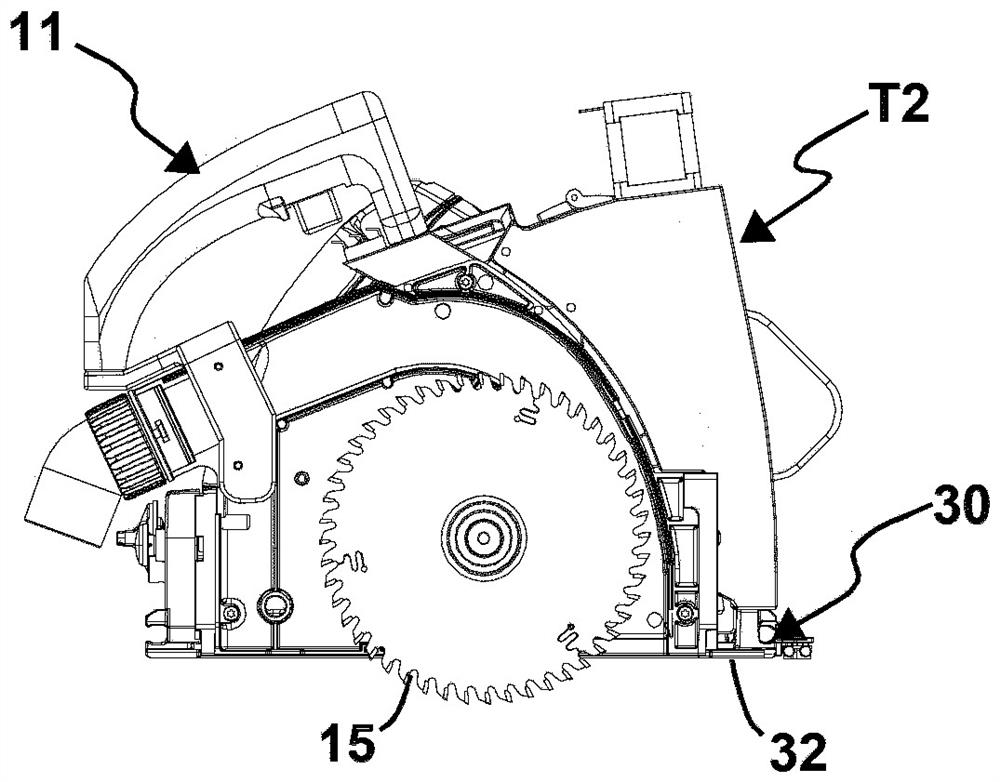

[0092] The machine tool 10 according to the figures has a guide element 30 with a guide plate 31 on which a guide surface 32 is arranged. A guide protrusion 52 of the guide receptacle 33 for guiding the guide rail 50 is provided at the guide surface 32 .

[0093] The machine tool 10 can be guided with its guide surface 32 directly along the workpiece surface WO of the workpiece W in order to introduce saw cuts thereon, for example. However, it is also possible to place the guide rail 50 with its bearing surface 53 on the workpiece surface WO in order to guide the machine tool 10 . The machine tool then slides with its guide surface 32 along a guide surface 51 which is arranged on the side of the guide rail 50 opposite the bearing surface 53 . Here, the guide projections 52 can engage into the guide receptacles 53 in order to guide the machine tool 10 in the normal working direction AR.

[0094] The machine tool 10 has a drive unit 11 with a drive motor 12 for driving the too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com