Pipe gallery transportation rail translation type turnout

A transportation track and translational technology, applied in the field of rail transportation, can solve the problem that the turnout cannot meet the requirements of the pipe corridor transportation track change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

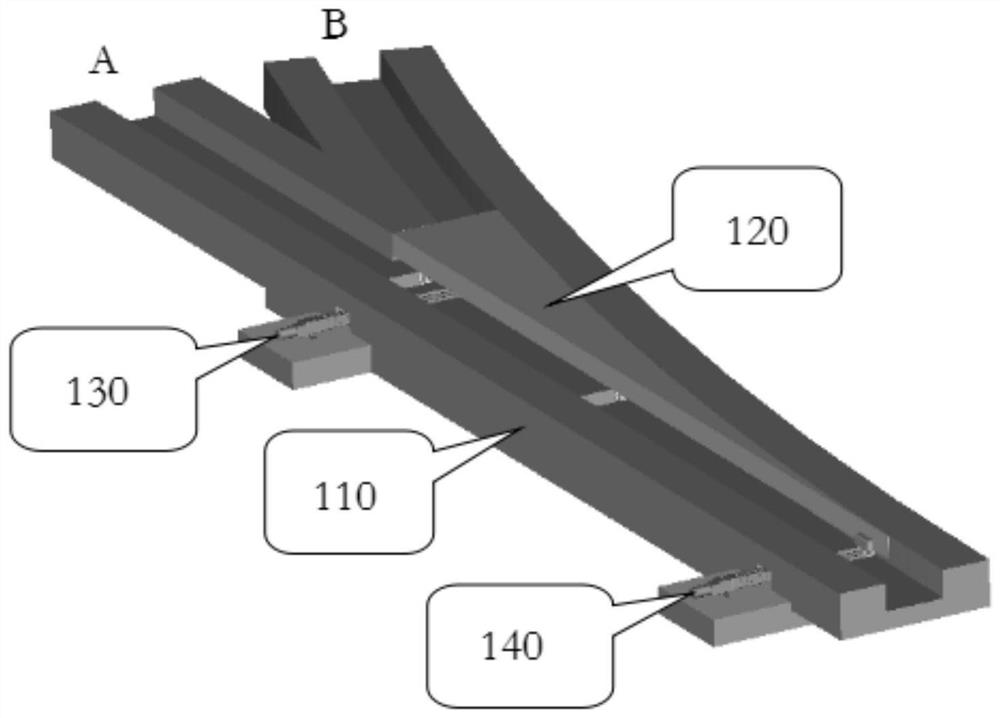

[0053] This embodiment provides a translational turnout for the transportation track of the pipe gallery, such as figure 1 shown, including:

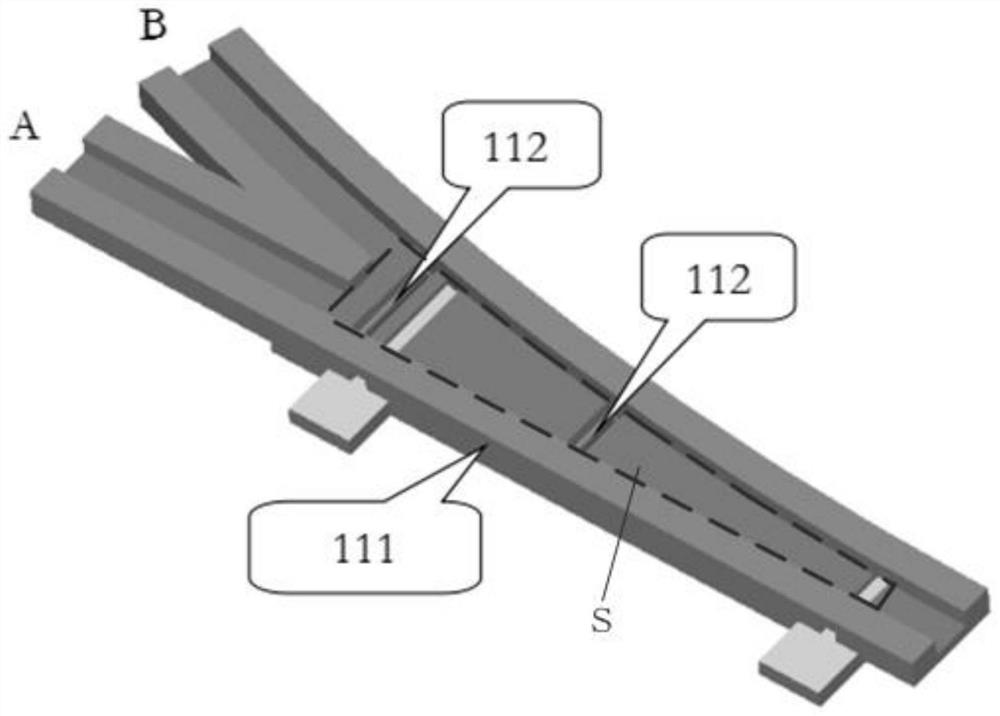

[0054] The turnout basic rail 110, the turnout basic rail 110 includes the A-share track and the B-share track, the turnout basic rail 110 adopts a pipe gallery transportation track structure, and there is a groove area S at the junction of the A-share track and the B-share track (such as figure 2 As shown, the groove area S is marked with a dotted line);

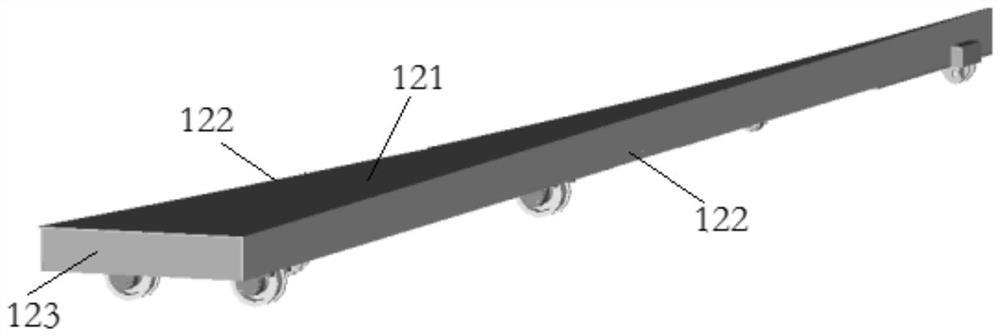

[0055] The switch moving rail 120 is arranged in the groove area S of the switch basic rail 110, and the switch moving rail 120 can move horizontally and laterally in the groove area S of the switch basic rail 110;

[0056] The switch driving device (for example: the main switch driving device 130 and the switch auxiliary driving device 140 ), connected with the switch moving rail 120 , is used to drive the switch moving rail 120 to move horizontally and laterally in the groove are...

Embodiment 2

[0090] This embodiment provides a pipe gallery transportation track structure, such as Figure 7 As shown, the structure is laid on the bottom of the pipe gallery. It is a "concave" track structure formed with the bottom of the pipe gallery. It is composed of two tracks. Carrier vehicles provide carrying and guiding functions.

[0091] Among them, the upper plane of the structure is the running rail surface; the two inner elevations of the groove in the middle of the track are the guide rail surface, which is located below the running rail surface.

[0092] Such as Figure 8 As shown, the running wheels (carrying wheels) of the utility vehicle run on the running rail surface of the track, and the guide wheels run on the guide rail surfaces on both sides of the groove in the middle of the track.

[0093] In the specific implementation process, the pipe gallery transportation track structure is the best choice to solve urban traffic congestion and environmental pollution. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com