3 Pillow Packing Machine Triple Center Sealing Device

A sealing device, packaging machine technology, applied in packaging sealing/fastening, packaging material feeding device, packaging, etc., can solve the problems of melting and cracking, inability to use thin films, easy tearing of films, etc., to improve quality and Reliability, cost savings, and aesthetically pleasing seals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

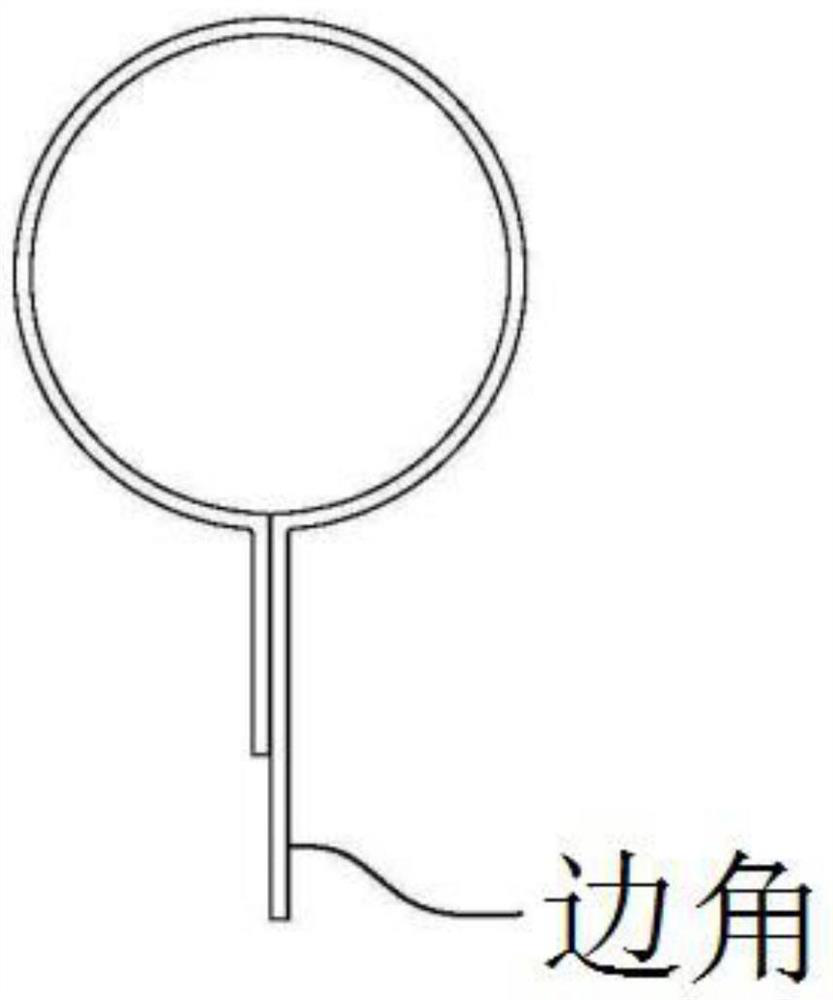

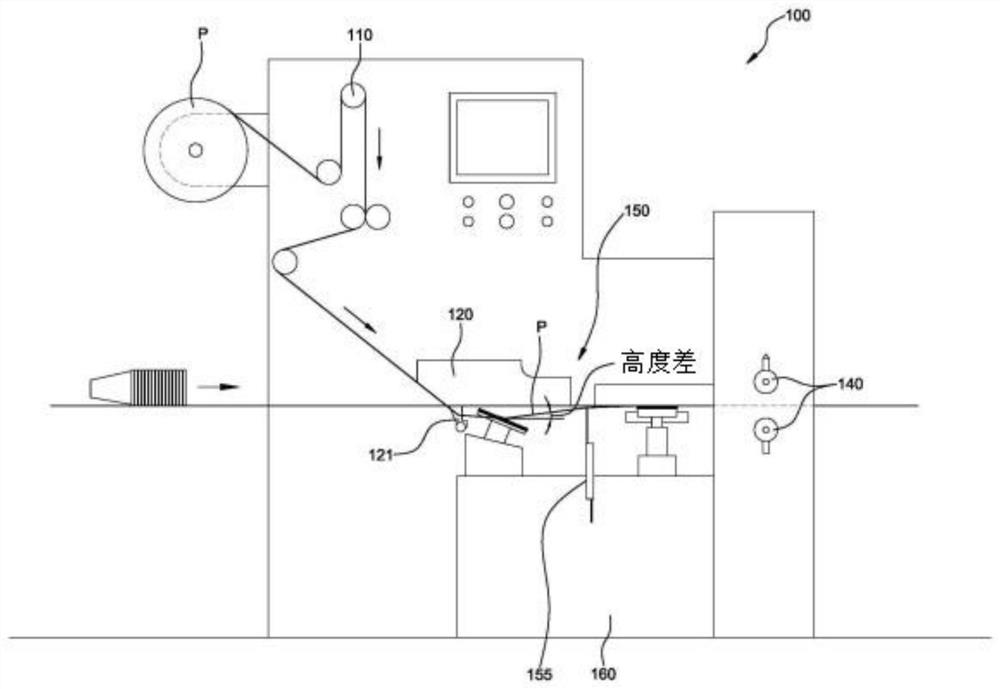

[0050] A triple center seal suitable for the pillow packaging machine of the present invention such as image 3 and even Figure 10 composition shown.

[0051]In order to describe the present invention below, if it is judged that the specific description of related known functions or configurations may unnecessarily obscure the gist of the present invention, the detailed description will be omitted.

[0052] In addition, the terms described later are terms set in consideration of the functions of the present invention, and may vary depending on the manufacturer's intention or customary practice, and therefore the definitions thereof are determined based on the entire content of the present specification.

[0053] In addition, the size and thickness of each component shown in the drawings are arbitrarily shown for convenience of description, and the present invention is not necessarily limited to those shown in the drawings.

[0054] First of all, the present invention relate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com