a cast explosive

A technology for melting and casting explosives and dinitrofurazanyl, which is applied in the direction of explosives, etc., can solve the problems of reducing the safety of explosives and insufficient metal acceleration ability, and achieves good safety performance, increased Gurney coefficient, and high metal acceleration ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The present invention is implemented with reference to the following mass percentage composition: 50% of 3,4-dinitrofurazan-based furoxan, 44% of 5,5-bitetrazole-1,1-dihydroxyammonium dioxide, 5% of aluminum powder %, 1% of 80# microcrystalline wax.

[0017] Preparation method: in a jacketed steam melting pot, melt 500g of 3,4-dinitrofurazan-based furoxan and 10g of microcrystalline wax, add 440g of 5,5-bitetrazole-1,1-di Dihydroxyammonium oxide and 50g of aluminum powder are mixed evenly and poured into a heat-resistant polyethylene plastic bag. After solidification, they are kneaded into powder and sieved to obtain a powder sample. Pour the powder into the mold and heat it to melt, and after natural cooling, the grain sample can be obtained.

Embodiment 2

[0019] The present invention is implemented with reference to the following mass percentage composition: 56% of 3,4-dinitrofurazan-based furoxan, 38% of 5,5-bitetrazole-1,1-dihydroxyammonium dioxide, 5% of aluminum powder %, 1% of 80# microcrystalline wax.

[0020] The manufacturing method of this example is carried out with reference to Example 1.

Embodiment 3

[0022] The present invention is implemented with reference to the following mass percentage composition: 45% of 3,4-dinitrofurazan-based furoxan, 43% of 5,5-bitetrazole-1,1-dihydroxyammonium dioxide, 10% of aluminum powder %, 80# microcrystalline wax 2%.

[0023] The manufacturing method of this example is carried out with reference to Example 1.

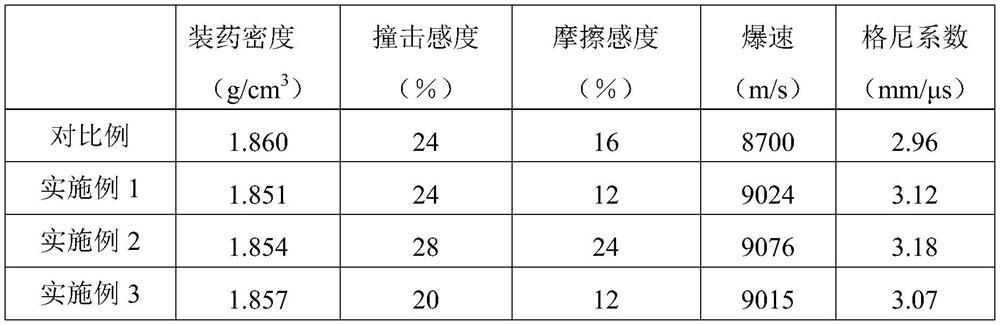

[0024] Table 1

[0025]

[0026] Compared with the comparative example, the present invention can greatly improve the detonation speed and the Gurney coefficient under the condition of the same charge density, wherein the detonation speed is increased by up to 2.99%, the Gurney coefficient is increased by up to 7.43%, and the mechanical sensitivity is comparable to the comparative example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com