Prefabricated box-type transformer substation

A box-type substation and pre-installed technology, applied in the field of substations, can solve the problems that pre-installed box-type substations cannot be converted to low voltage, do not have ordinary low voltage and isolation voltage, and cannot respond to sudden problems in time. To achieve the effect of reducing the cost of substation, convenient management of power transmission, and meeting the needs of safe power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

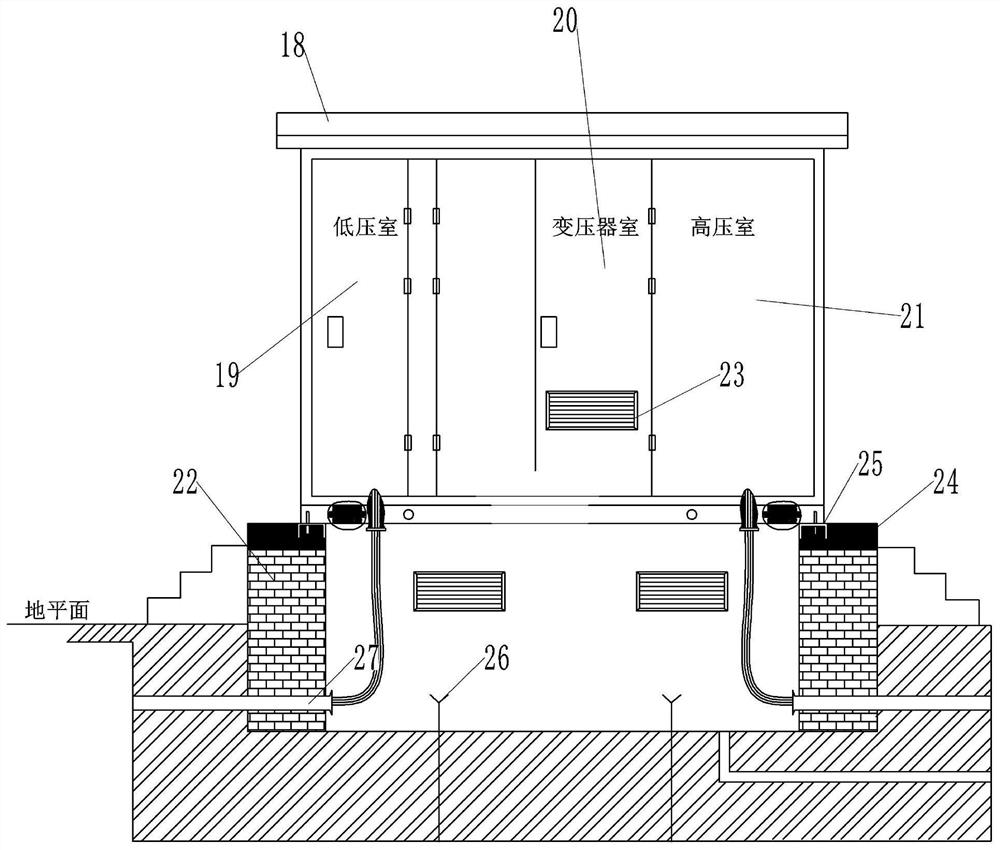

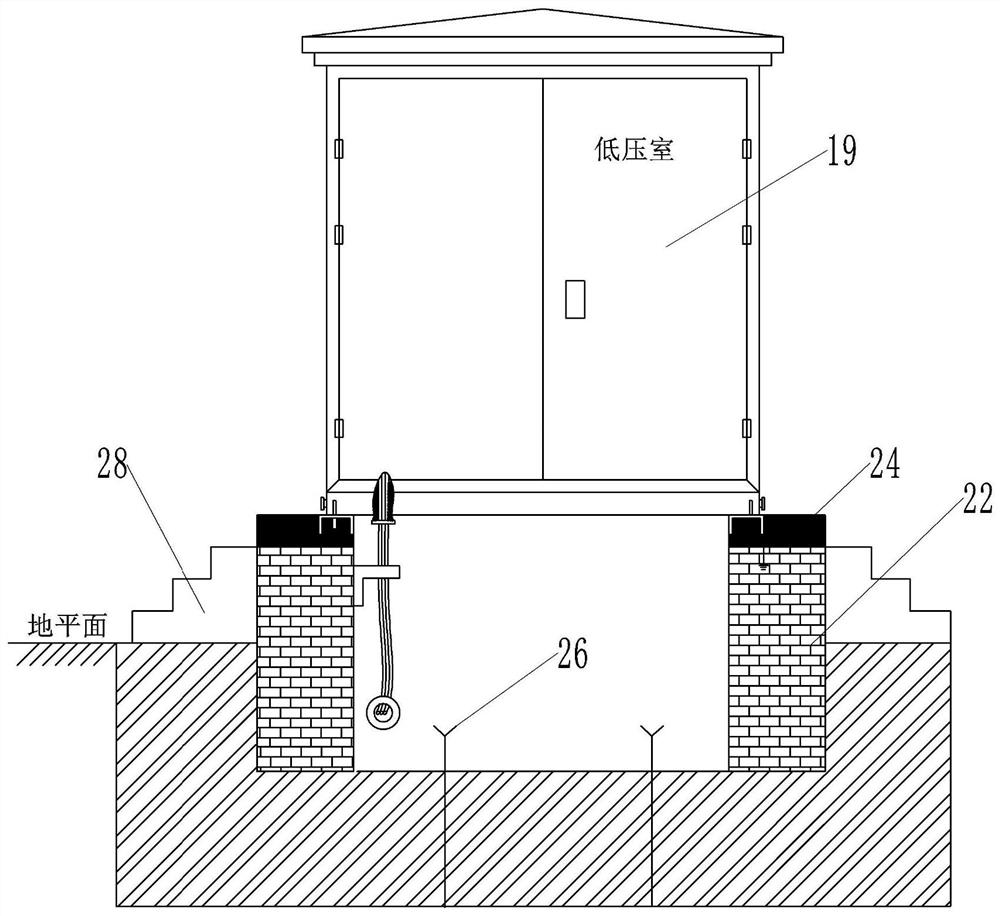

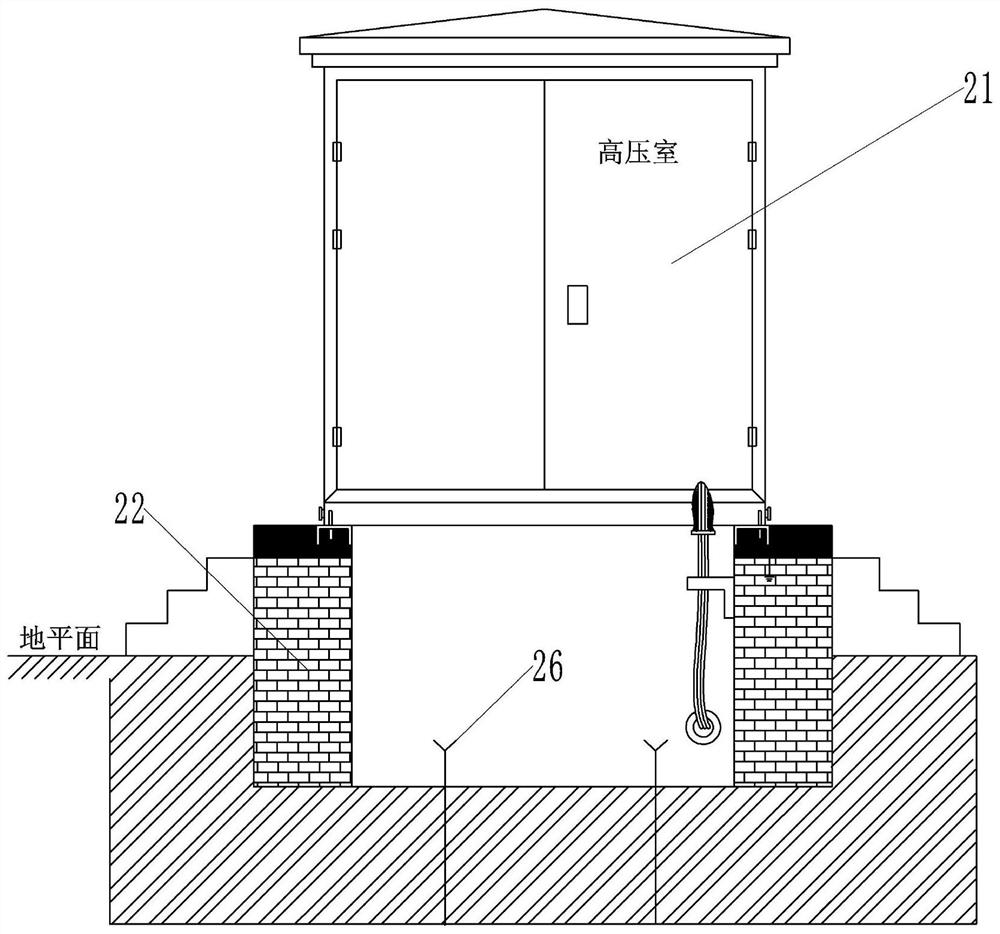

[0019] The reference signs in the drawings of the description include: substation shell 18, low-voltage room 19, transformer room 20, high-voltage room 21, brick wall 22, ventilation window 23, concrete ring beam 24, channel steel 25, grounding iron 26, cable hole 27, maintenance ladder 28, dividing plate 29.

[0020] The specific implementation process is as follows:

[0021] Such as Figure 1-Figure 5 As shown, a prefabricated box-type substation mainly includes a substation shell 18, an installation base and a transformer. The transformer adopts a high-performance dual-output transformer, and the transformer is installed inside the substation shell 18. The upper end of the base is fixedly connected.

[0022] The interior of the substation shell 18 is provided with a partition 29, and the partition 29 is used to divide the interior of the substation shell 18 into three parts, na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com