Dehumidification mechanism of hardware storage cabinet and working method thereof

A storage cabinet and hardware storage technology, which is applied to the cleaning method of tools, metal processing equipment, cleaning methods and utensils, etc., can solve the problems of labor-intensive, low cleaning efficiency, incomplete cleaning, etc., and achieves reduction of manual turnover and dehumidification. Thoroughly improve the effect of dehumidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

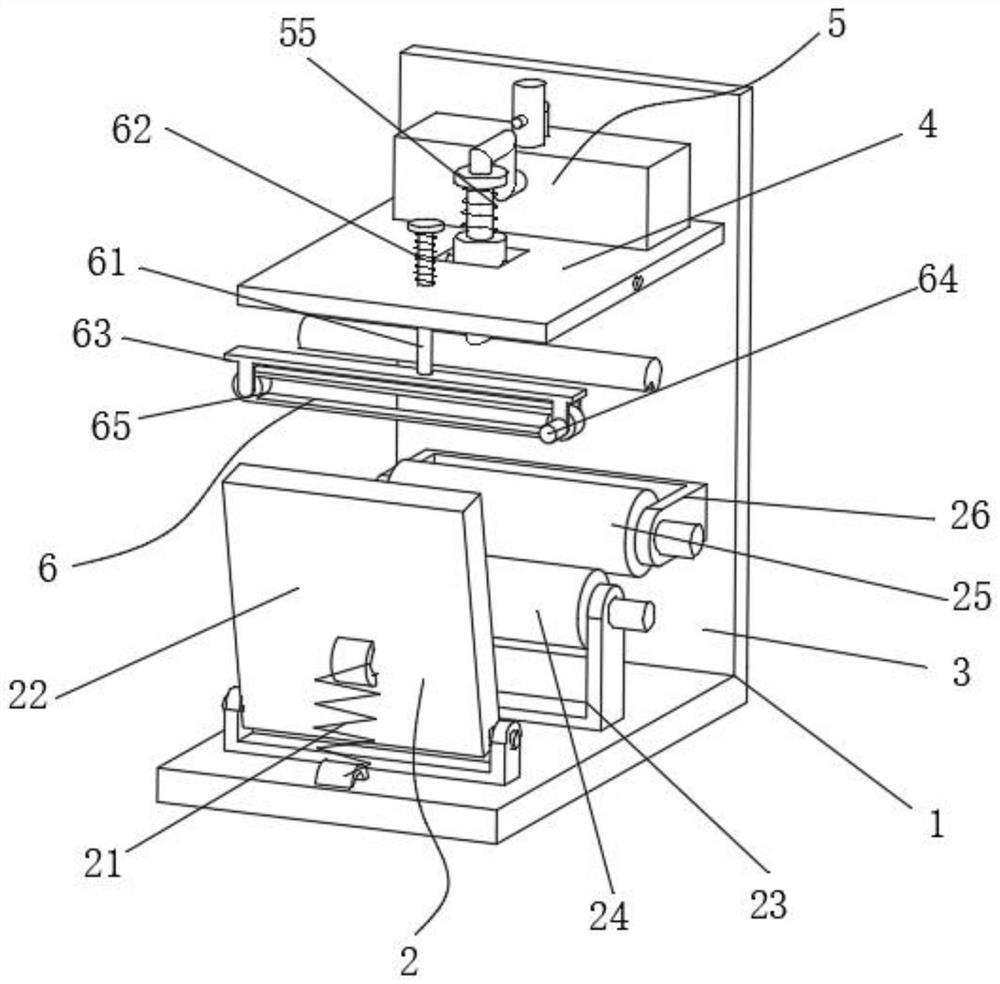

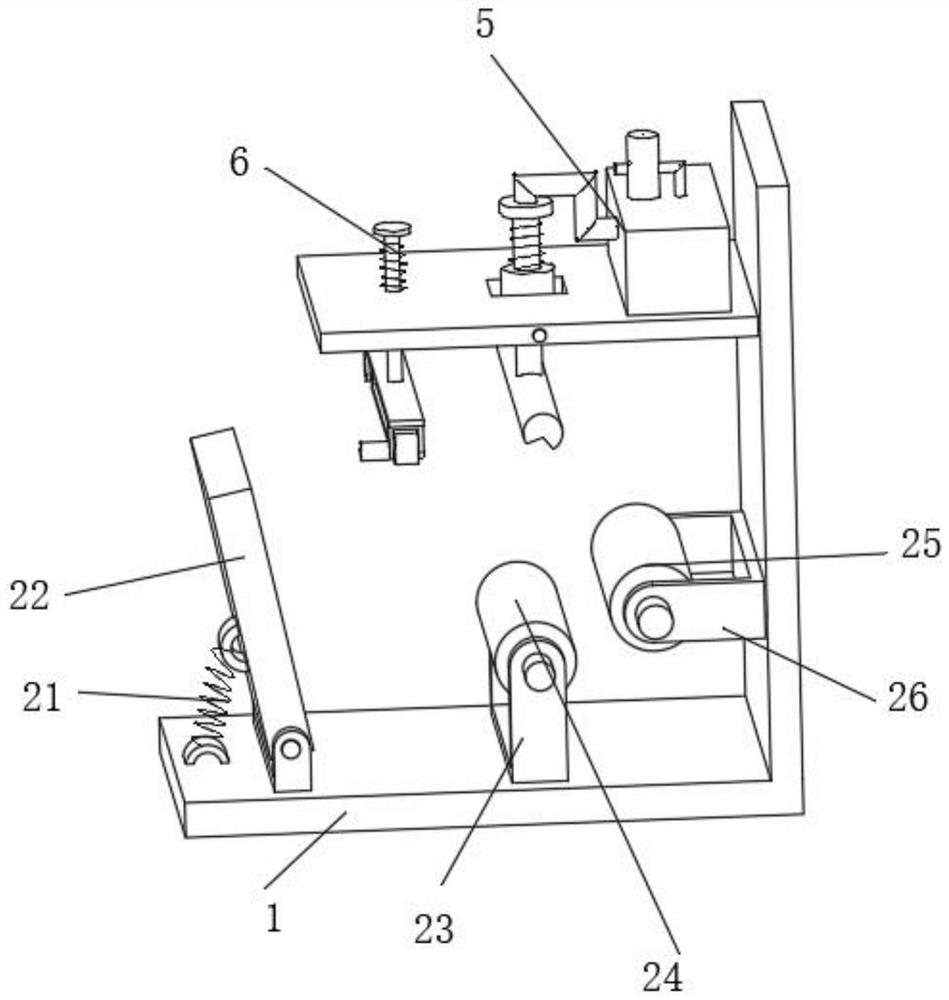

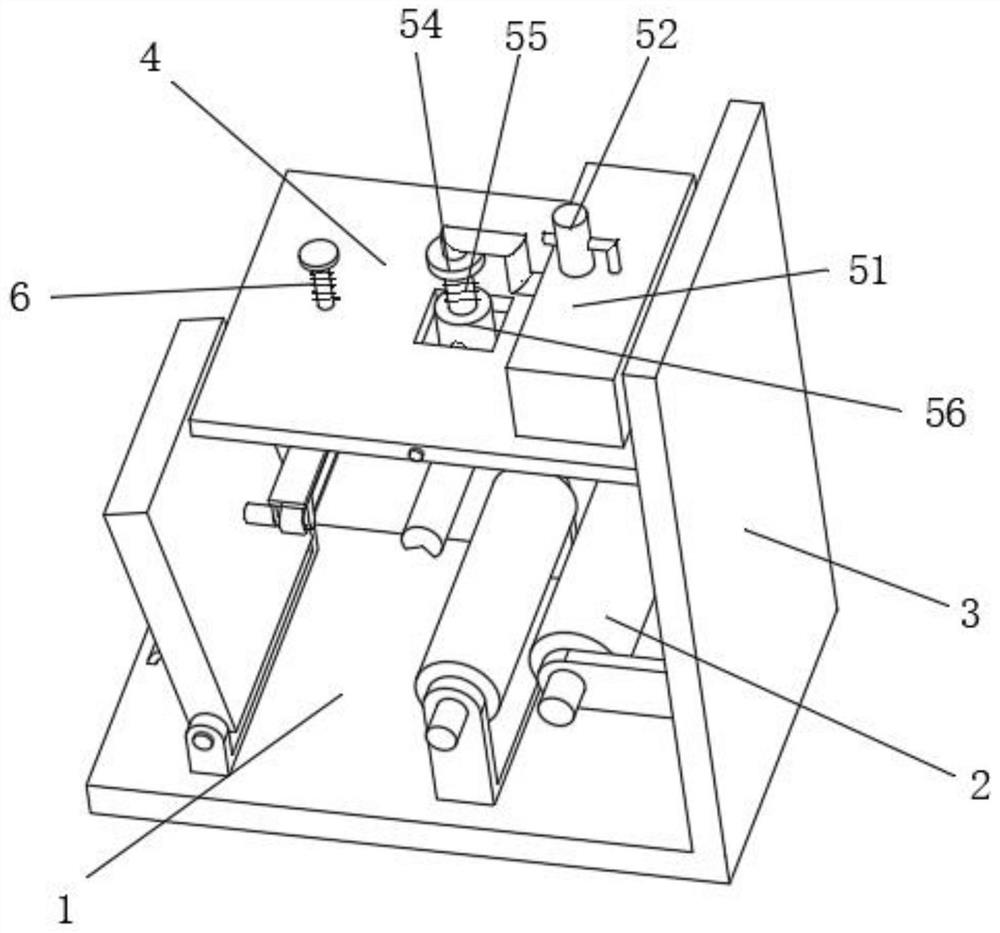

[0030] As an embodiment of the present invention, the clamping and turning structure 2 includes a clamping spring 21, a clamping plate 22, a first roller frame 23, a first rubber roller 24, a second rubber roller 25, and a second roller frame 26. The holding plate 22 is mounted on the top side of the base 1 through a hinge, the bottom side of the clamping plate 22 and the top side of the base 1 are fixed with a clamping spring 21 at an oblique angle, and the first roller frame 23 is welded on the On the top side of the base 1, the first rubber roller 24 is installed inside the first roller frame 23 through the roller shaft fit, the second roller frame 26 is welded on one side of the fixed plate 3, and the second rubber roller 25 is fitted through the roller shaft Installed on the second roll frame 26, the first roll frame 23 and the second roll frame 26 are arranged at right angles, and the clamping plate 22 is arranged in parallel with the first rubber roller 24. During work, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com