Drum-type laminator with controllable laminating distance for PVC films

A roller type, laminating machine technology, applied in the field of floor laminating machine, can solve the problems of uneven PVC film lamination, complicated process, time-consuming and labor-intensive, etc., and achieve the effect of precise length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

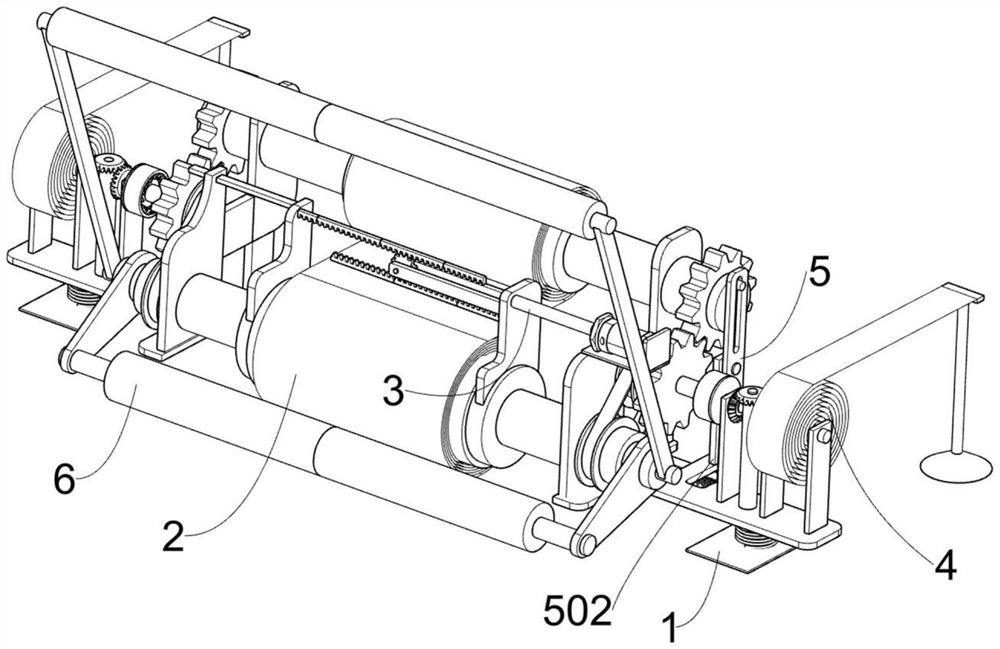

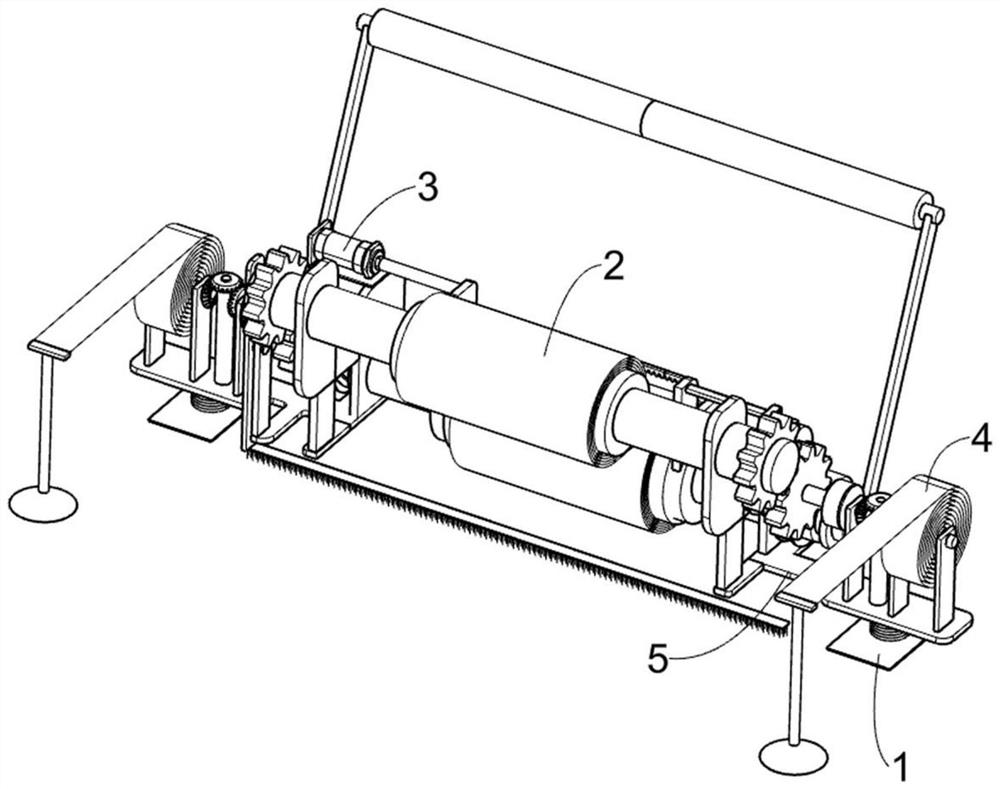

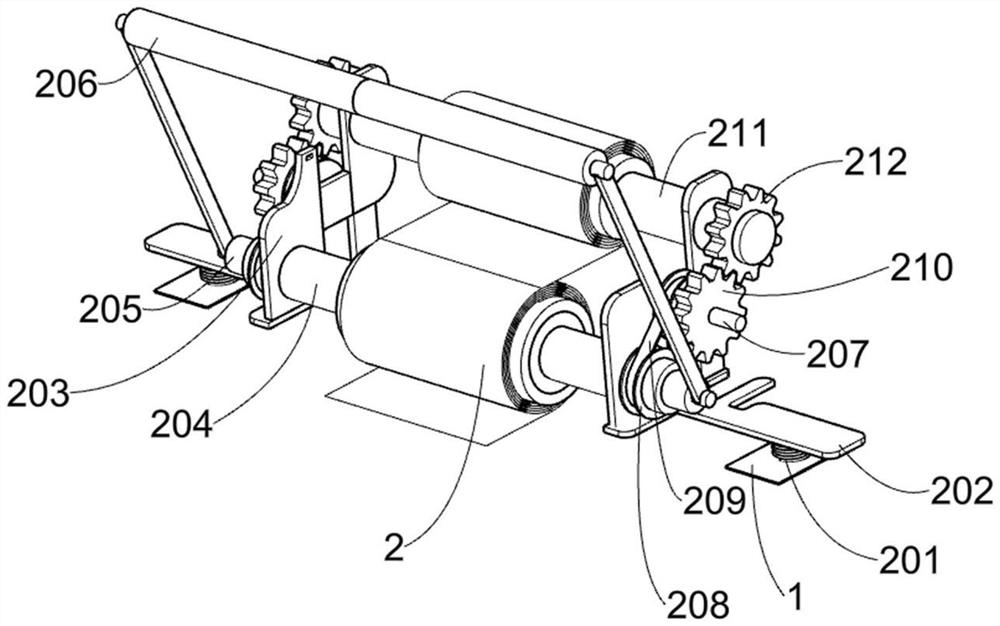

[0020] Embodiment: a kind of roll-type laminating machine with controllable lamination distance for PVC film, such as Figure 1-7 As shown, it includes a first support plate 1, a roller-type film-attaching mechanism 2, a clamping mechanism 3, a distance control mechanism 4 and a cleaning mechanism 5, and the roller-type film-attaching mechanism 2 for bonding the PVC film to the floor is set On the two first support plates 1, the clamping mechanism 3 for clamping the rolled PVC film is arranged on the roller type film sticking mechanism 2, and the distance control for controlling the length of the PVC film is pasted. The mechanism 4 is arranged at both ends of the roller-type film-attaching mechanism 2 , and the cleaning mechanism 5 for cleaning the position where the film-attachment needs to be performed is arranged at one side of the roller-type film-attaching mechanism 2 .

[0021] Specifically, the drum-type film sticking mechanism 2 includes a spring 201, a bottom plate 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com