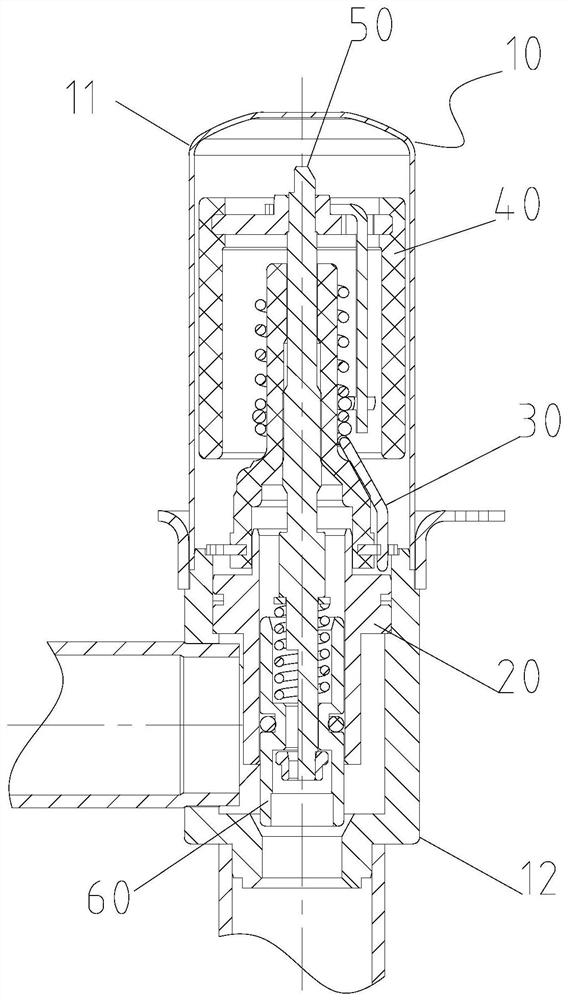

Electronic expansion valve

A technology of electronic expansion valve and valve seat, which is applied in the direction of lifting valve, valve device, valve details, etc., can solve the problem of low coaxiality and achieve the effect of ensuring coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The assembly steps of the device provided in Embodiment 1 are:

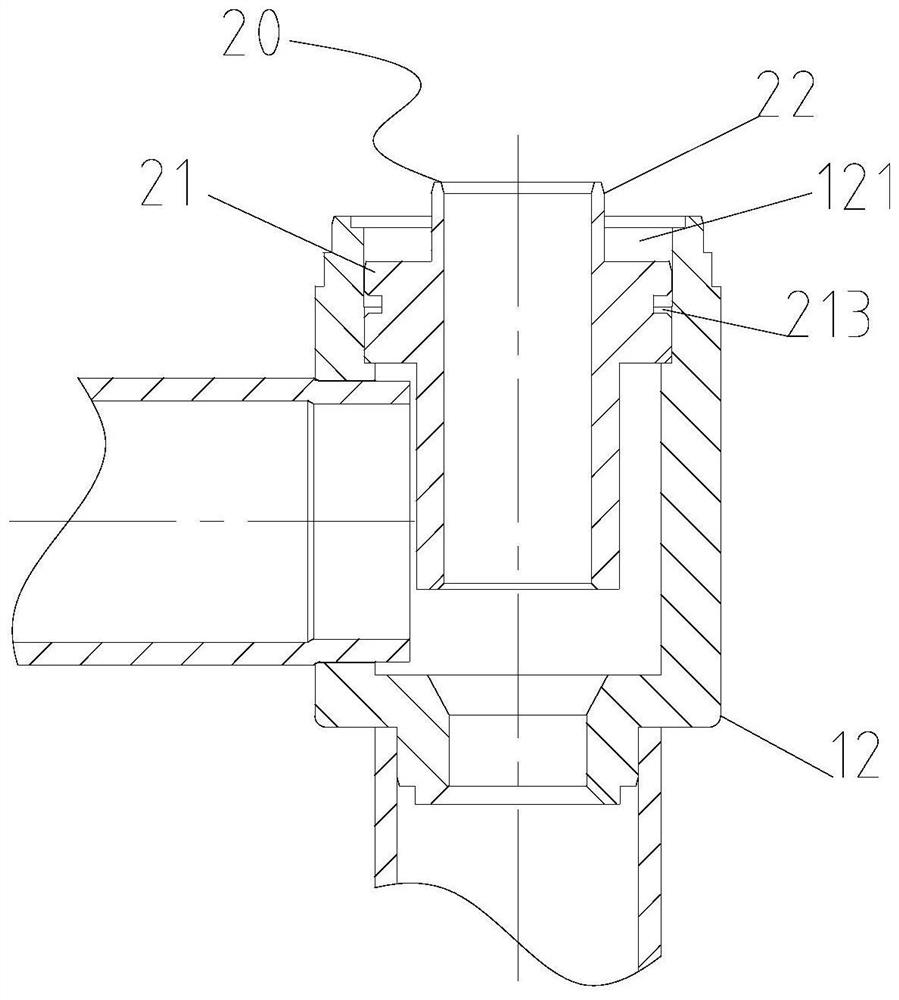

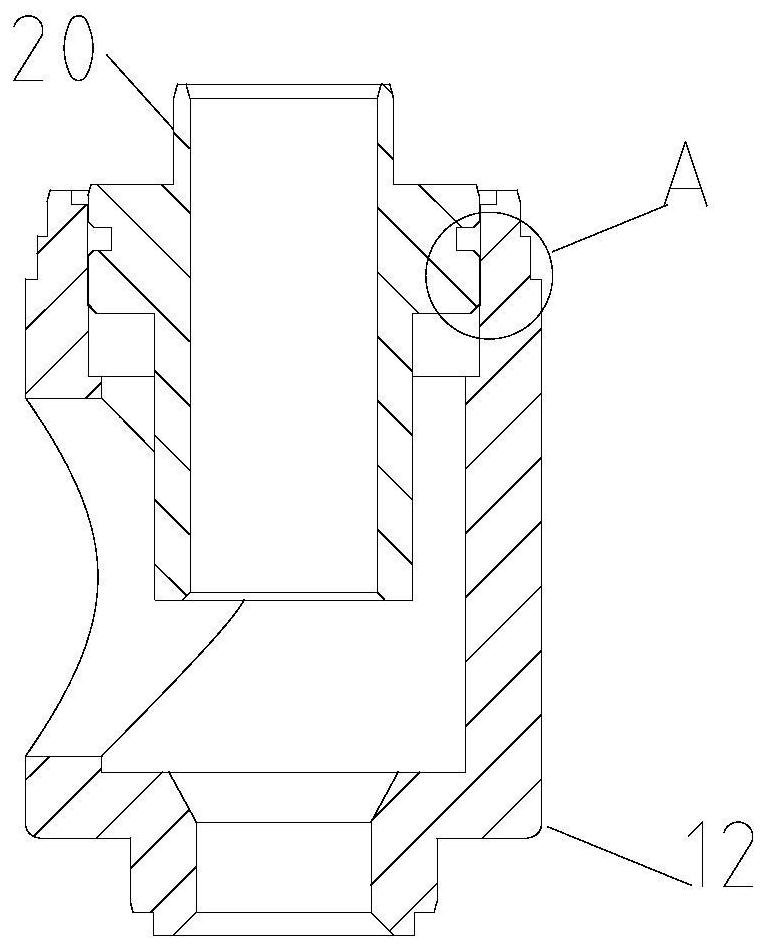

[0050] (1) Put the guide sleeve 20 into the valve seat 12, the fourth section 212 of the guide sleeve 20 is in clearance fit with the first section 121a of the valve seat 12, so that the guide sleeve 20 can be positioned and guided;

[0051] (2) Press-fit the guide sleeve 20 so that the lower surface of the installation boss 21 is in contact with the stepped surface of the limiting boss 121c, and the fourth section 212 of the guide sleeve 20 is closely matched with the second section 121b of the valve seat 12 . At this time, there is a gap of 0.01mm to 0.04mm on one side between the third section 211 of the guide sleeve 20 and the first section 121a of the valve seat 12 as a welding seam, and a welding ring is placed in the welding ring groove 213;

[0052] (3) Assemble the first pipe fitting and the second pipe fitting on the valve seat 12 , and weld the first pipe fitting, the second pipe fitting, the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com