Heavy-load AGV transport vehicle

A technology of transport vehicles and expansion plates, which is applied in the field of AGV transport vehicles, can solve the problems of inability to transport goods and insufficient flexibility in transporting goods, and achieve the effects of good shock absorption, flexible use, and improved capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

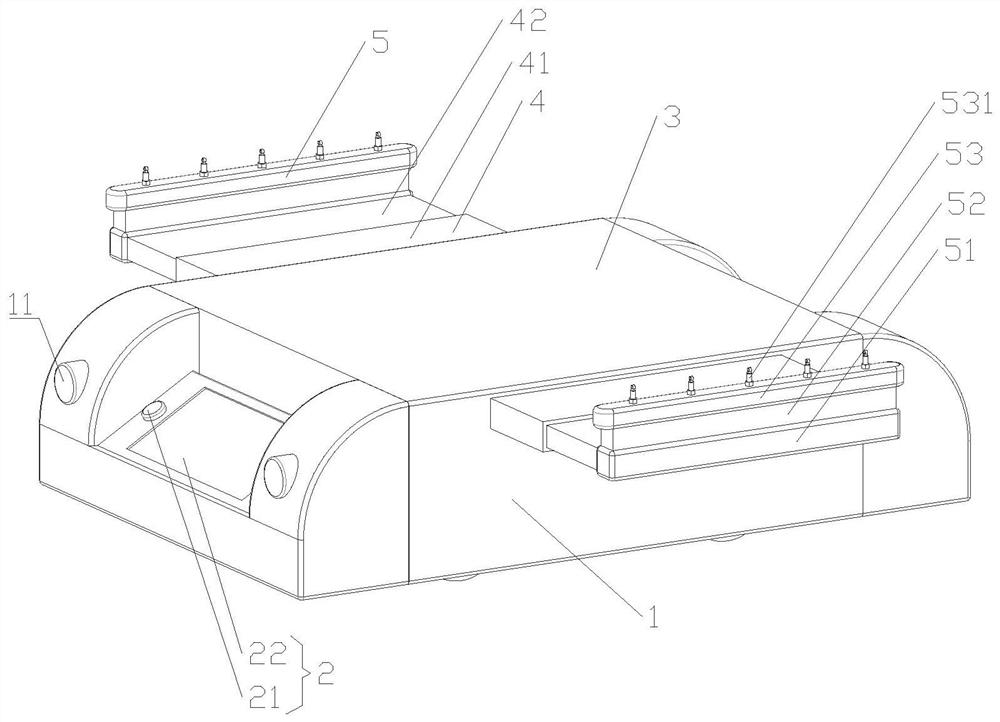

[0016] Such as figure 1 As shown, a heavy-duty AGV transport vehicle provided by the present invention includes an AGV transport vehicle 1, a control host, a display control panel 2, a load plate 3, a shock absorber, a first telescopic plate assembly 4 and a second telescopic plate assembly 5. The control host is installed inside the AGV transport vehicle 1. The control host is electrically connected to a WIFI module. The display control panel 2 is embedded in the rear end of the AGV transport vehicle 1. A shock absorber is installed on the top of the AGV transport vehicle 1. The top of the device is fixedly connected to the load plate 3, the left and right sides of the AGV transport vehicle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com