Vacuum-adsorbing screw loading device

A vacuum adsorption and screw technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of loud air blowing pipe noise, easy to cause danger, and screws cannot pass through, so as to prevent air pipe blockage, avoid excessive noise, and reduce downtime. The effect of feeding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

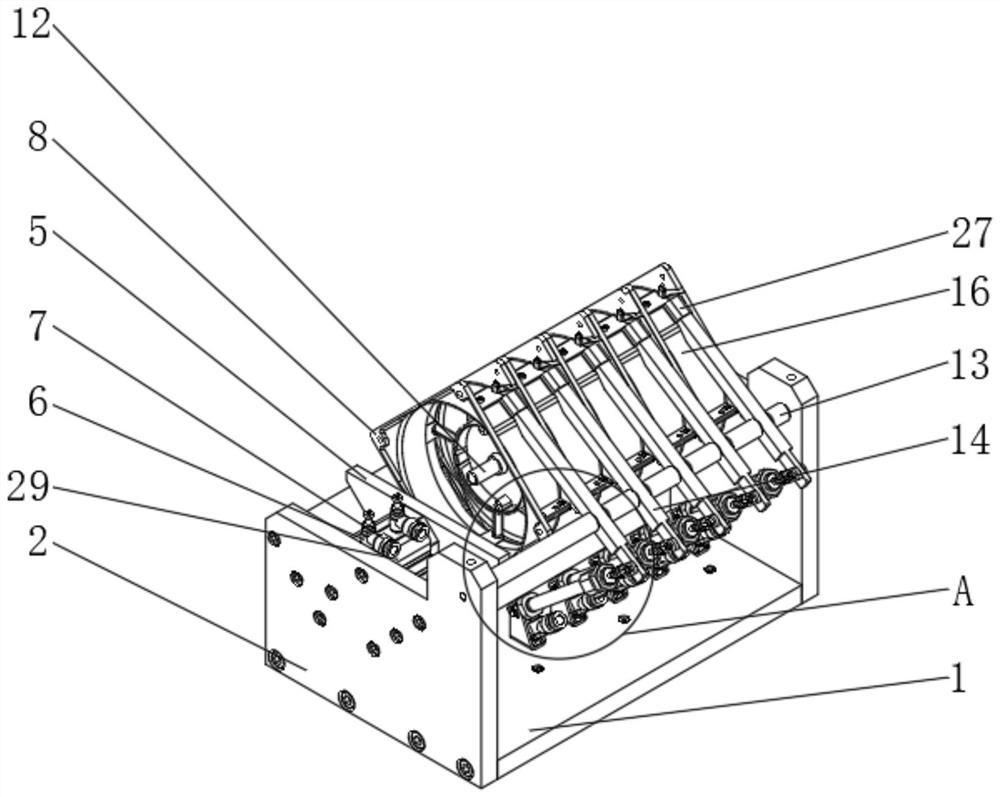

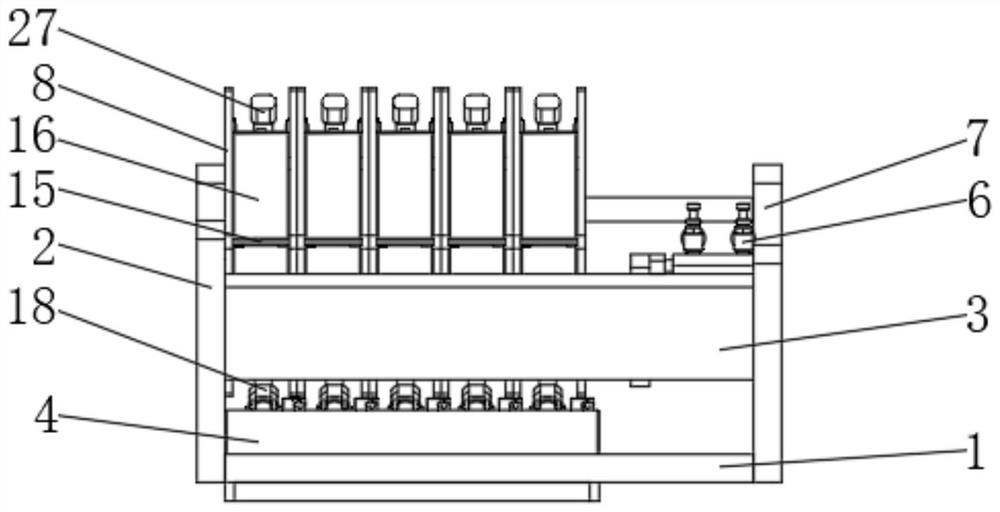

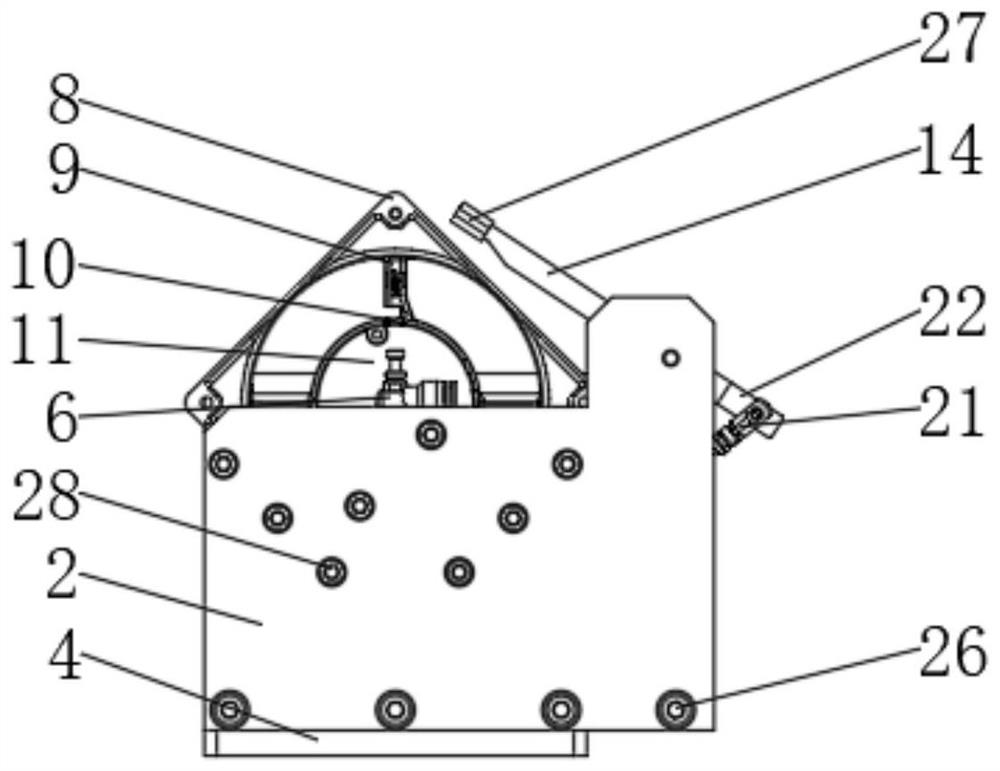

[0025] A vacuum adsorption screw-up device, comprising a base 1, a fixed plate 2, an inclined plate 3, a controller 4, a baffle plate 5, an adapter 6, a connection port 7, an installation frame 8, a limit rod 9, and a sliding sleeve 10. The outer side of the base 1 is connected with a fixed plate 2 by bolts, the inner side of the fixed plate 2 is connected with a slant plate 3 by bolts, the inside of the base 1 is fixedly sleeved with a controller 4, and the slant plate 3 The inner side of the baffle plate 5 is fixedly connected with a baffle plate 5, the outer side of the baffle plate 5 is fixedly connected with a connecting block 29, the inner side of the slant plate 3 is fixedly connected with a mounting frame 8, and the inside of the mounting frame 8 is fixedly connected with a limit rod 9 A sliding sleeve 10 is fixedly connected to the inner side of the limiting rod 9 , a driving cylinder 11 is slidingly connected to the inside of the sliding sleeve 10 , and an air nozzle ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap