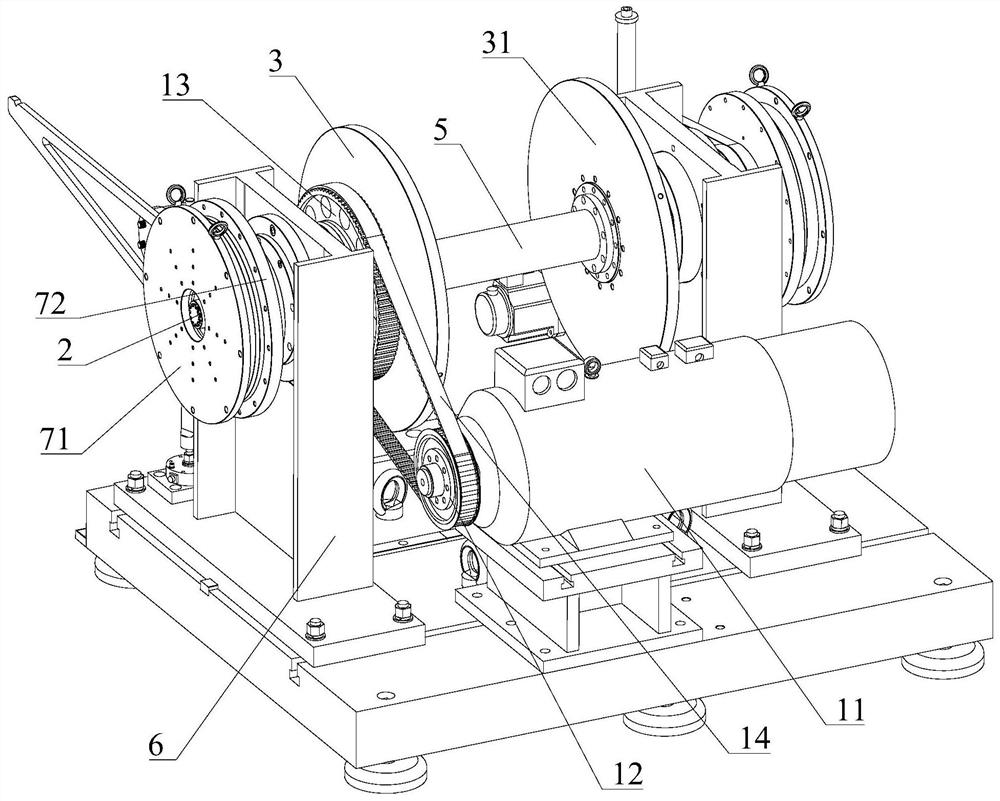

Torsional fatigue test driving mechanism, testing machine, testing method and storage medium

A technology of torsional fatigue and driving mechanism, applied in the field of torsional fatigue test, can solve the problems of high use cost, high energy consumption, low energy consumption and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

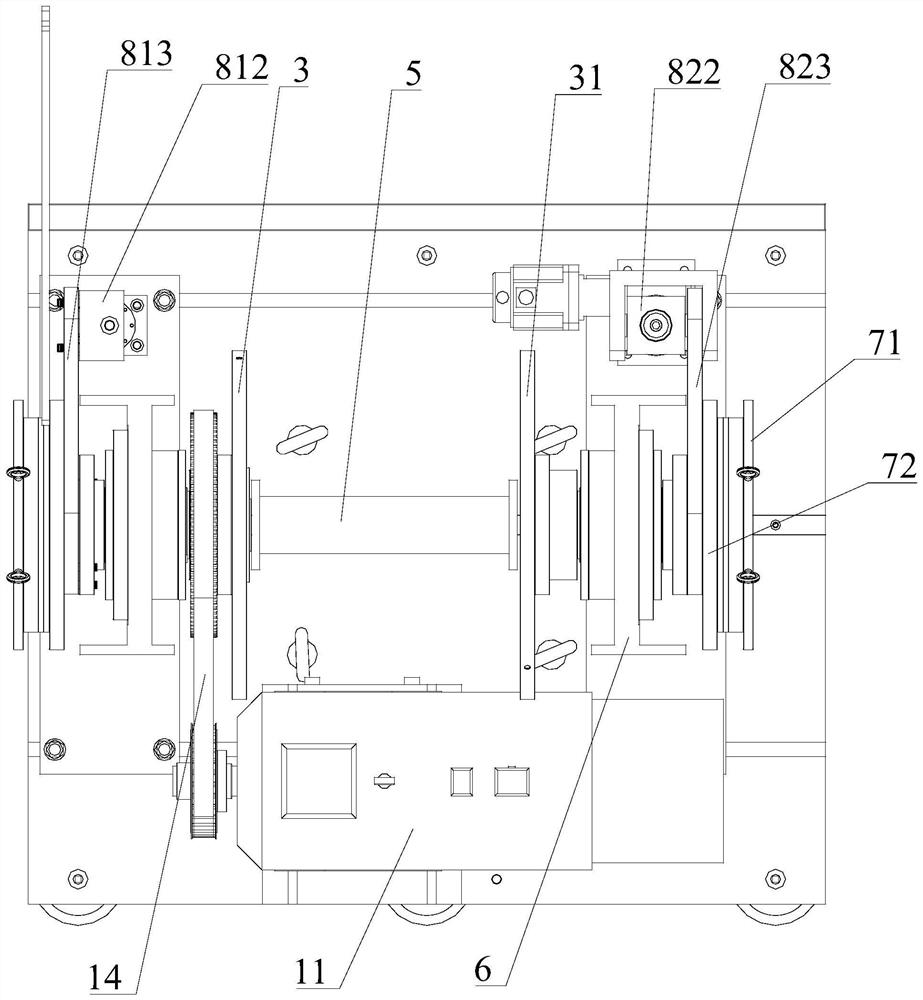

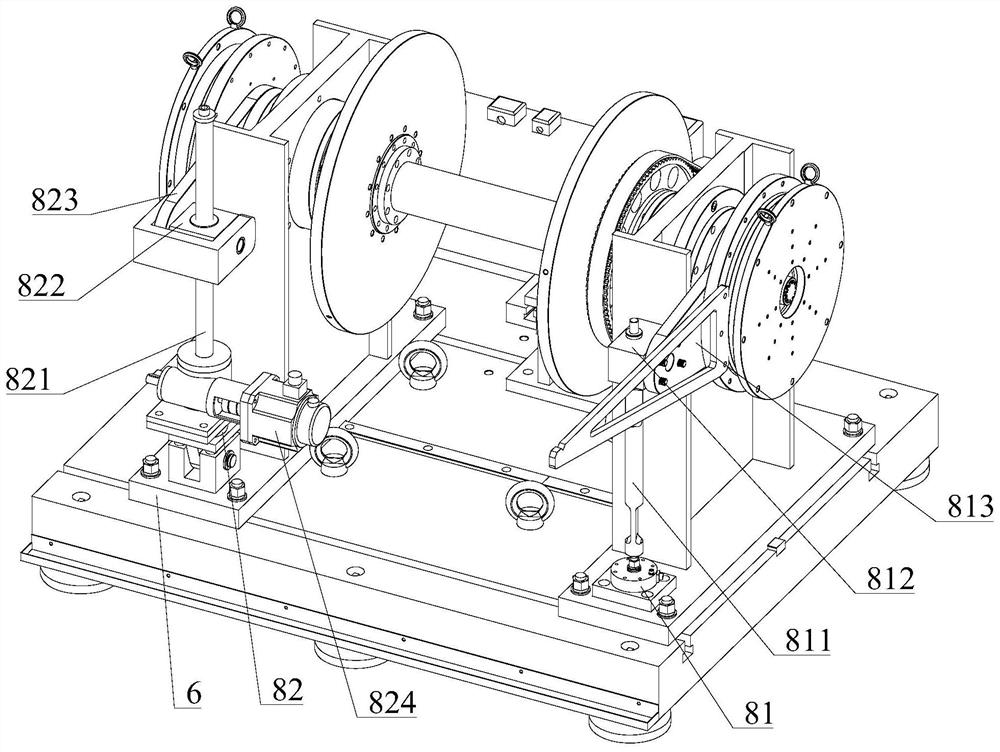

Method used

Image

Examples

specific Embodiment approach 1

[0107] It includes the following steps: determine the torsion angle α required for the torque fatigue test of the main specimen; the power source gradually increases the input torque so that the main specimen performs simple harmonic vibration in the range of positive and negative α angles; intermittently drives the spring vibrator to compensate The energy loss of the spring vibrator during the simple harmonic vibration to maintain the simple harmonic vibration of the spring vibrator.

specific Embodiment approach 2

[0109] Include the following steps:

[0110] Determine the torque boundary value required for the torque fatigue test of the main specimen; the power source gradually increases the input torque so that the main specimen reaches the torque boundary value and generates simple harmonic vibration in the positive and negative β angle interval; the torsion measuring mechanism detects the main specimen The difference between the current torque value and the torque boundary value; according to the feedback of the torsion measuring mechanism, the difference is dynamically compensated by the work done by the power source, so as to maintain the simple harmonic vibration of the spring vibrator.

[0111] It should be noted that the β angle is not preset, and the β angle is determined according to the torque boundary value, that is, the magnitude of the torque boundary value determines the size of the β angle.

[0112] It should also be noted that, in the second specific embodiment, the tor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com